Isophase differential beam forming device

A beam and sliding device technology, which is applied in the field of phase difference beamforming devices, can solve problems such as increased loss, large insulator area, and distribution constraints, and achieve the effects of easy bending and deformation, reduced manufacturing costs, and avoided loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] For reasons of convenience only, in the following description, specific directional terms, such as "up", "down", "left", "right", etc., are used with reference to the corresponding drawings and It should not be regarded as a limitation on the present invention, and when the defined direction of the drawings changes, the directions indicated by these words should be interpreted as correspondingly different directions.

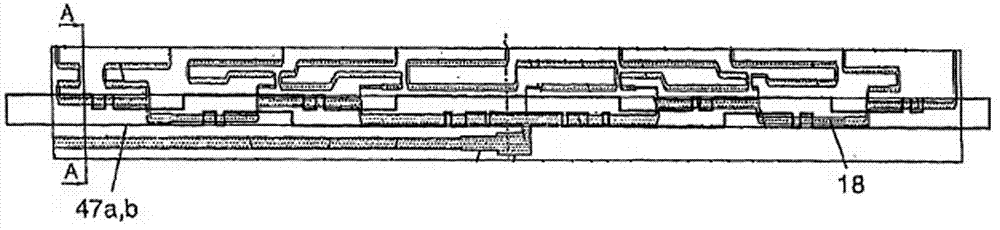

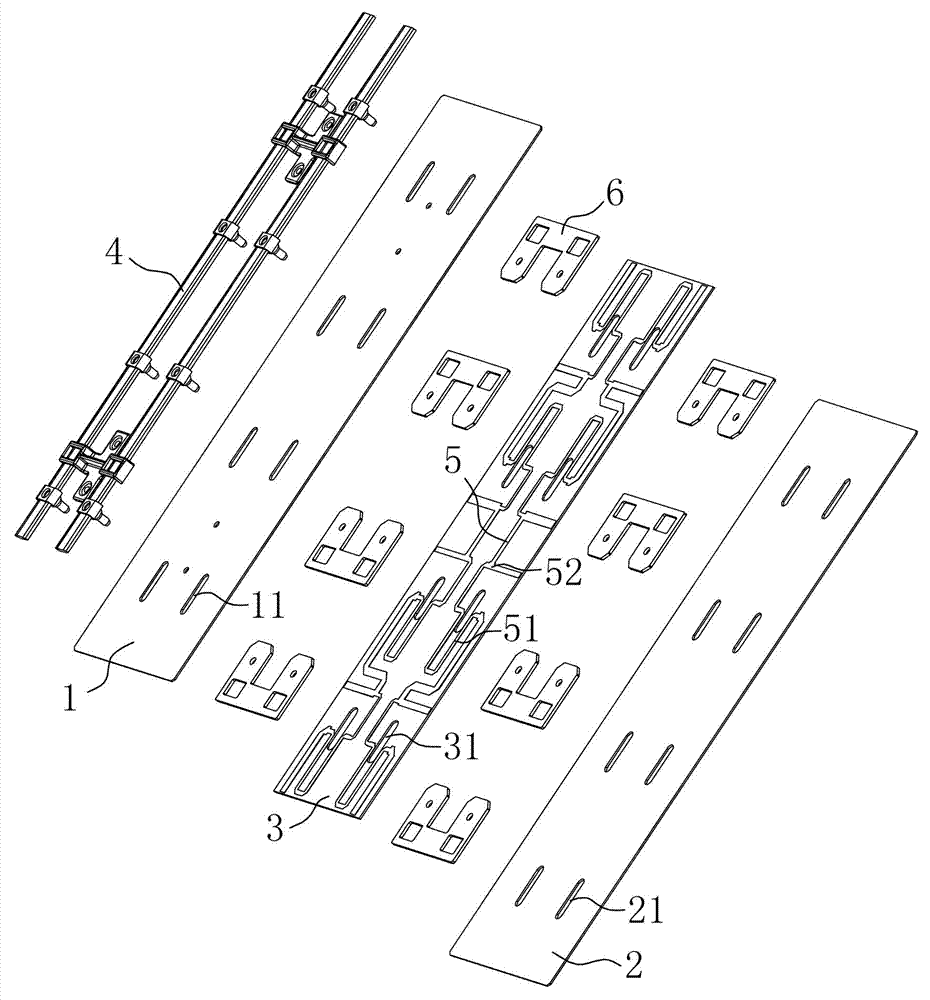

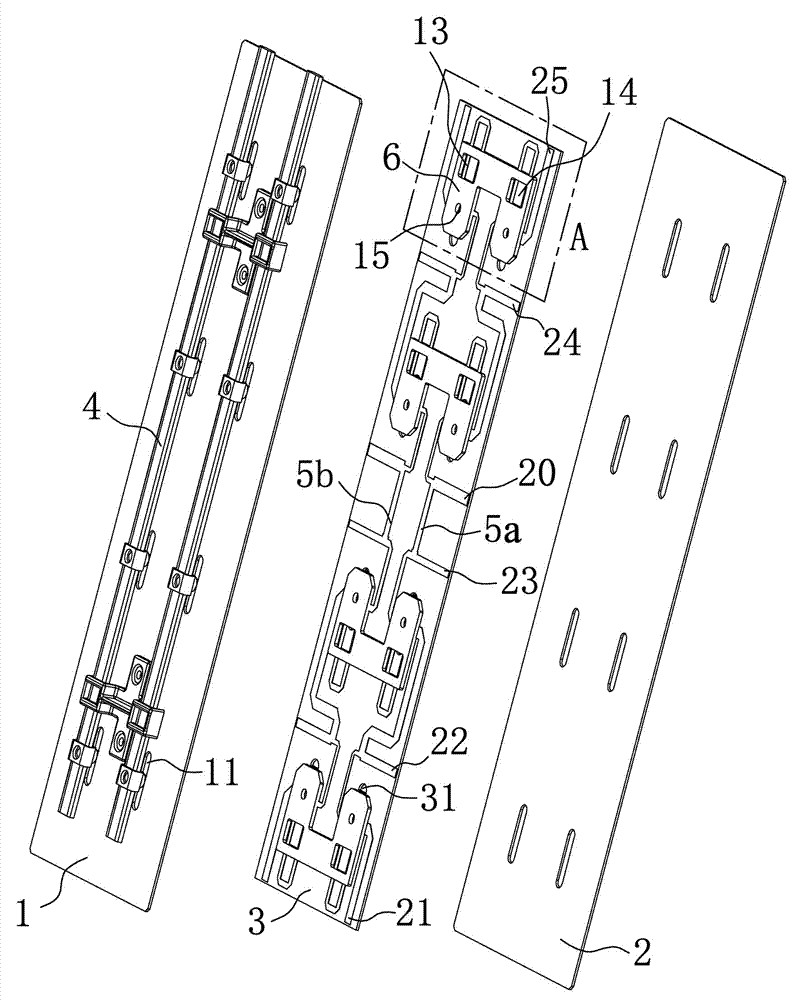

[0031] see figure 2 The equal-phase differential beamforming device provided by the embodiment of the present invention includes a first metal reflector 1, a second metal reflector 2, an insulating dielectric sheet 6, a sliding device 4, a dielectric substrate 3, and a feeder network etched on the dielectric substrate 3 5. The feeder network 5 includes fixed transmission lines 51 and power distribution subunit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com