Improved spark plug

A technology of spark plugs and jet holes, which is applied in the field of internal combustion engine parts, can solve the problems of reduced fuel combustion efficiency, increased hydrocarbon displacement, engine power loss, etc., and achieves the effects of enhancing ignition efficiency, strong flame, and large range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

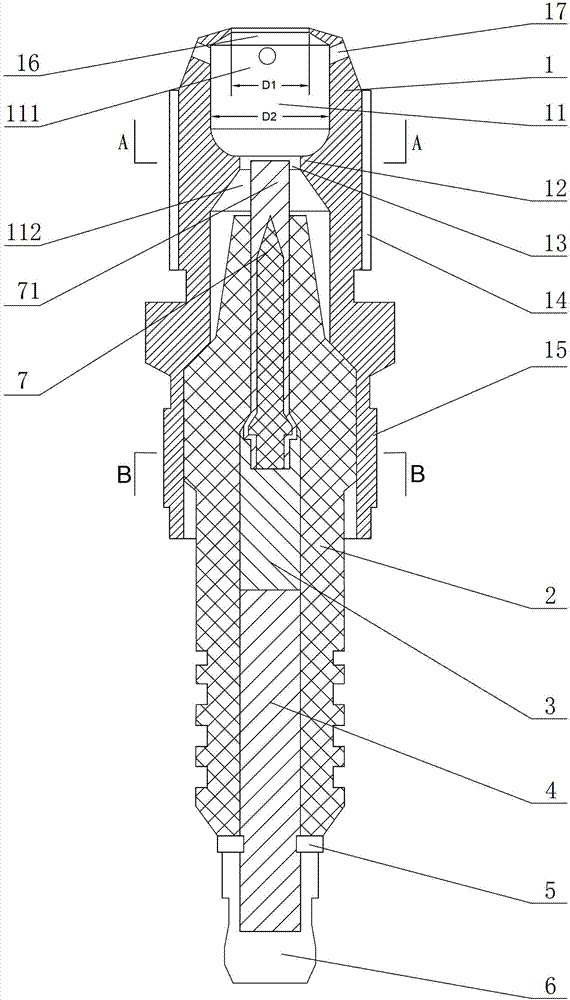

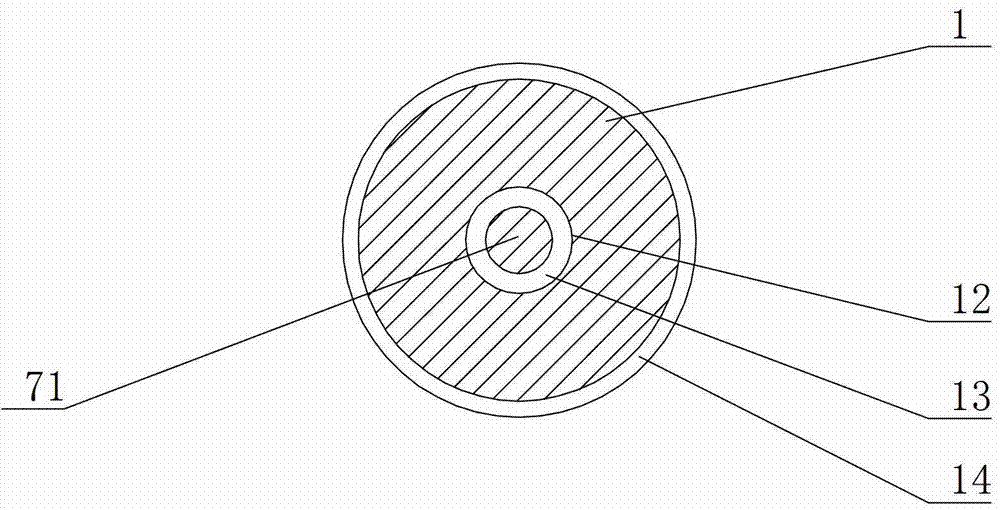

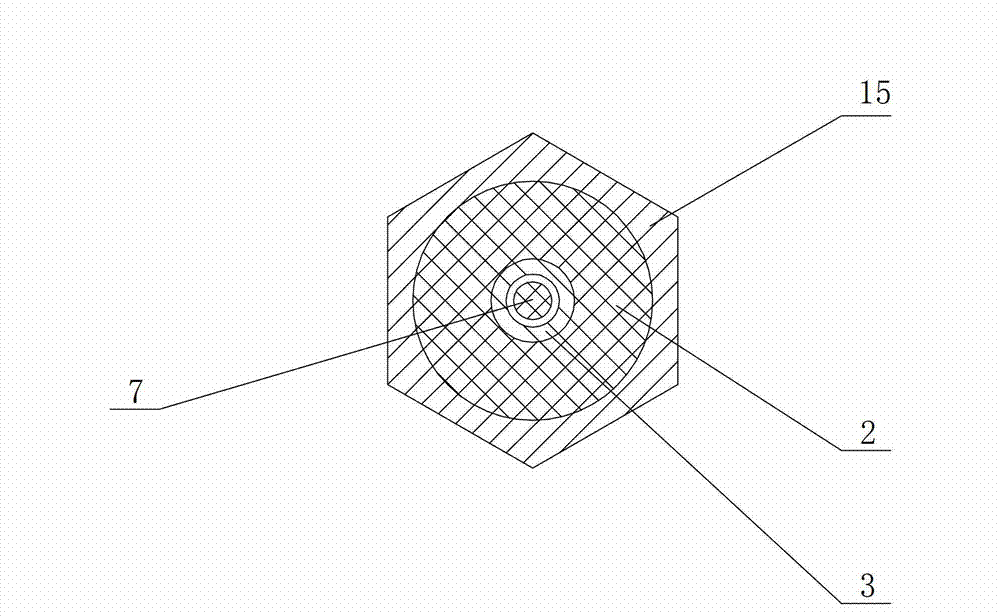

[0012] Below in conjunction with accompanying drawing, the preferred embodiment of a kind of improved spark plug of the present invention is described in detail:

[0013] figure 1 What is shown is a structural schematic diagram of an improved spark plug of the present invention. Like the conventional spark plug, the improved spark plug is installed on the cylinder head of the internal combustion engine for use. The improved spark plug mainly includes a shell 1 and an insulating ceramic core 2 . Shell 1 is made of steel, such as figure 2 As shown, the upper end of the shell 1 is cylindrical, and the outer wall of the cylinder is provided with threads 14, which are used to seal the spark plug on the cylinder head, as image 3 As shown, the lower end of the shell 1 has a hexagonal tail 15 to adapt to the twisting of the pipe wrench.

[0014] The inside of the casing 1 is a cavity that penetrates up and down. The upper half of the cavity is a fire-spraying chamber 11 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com