Hybrid beans vine-breaking mechanism of harvester

A kind of miscellaneous beans and frame technology, which is applied in the direction of agricultural machinery and implements, harvesters, applications, etc., can solve the problems of tractor pile congestion and failure of implements, and achieve reliable operation, strong adaptability, and structure Design novel and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

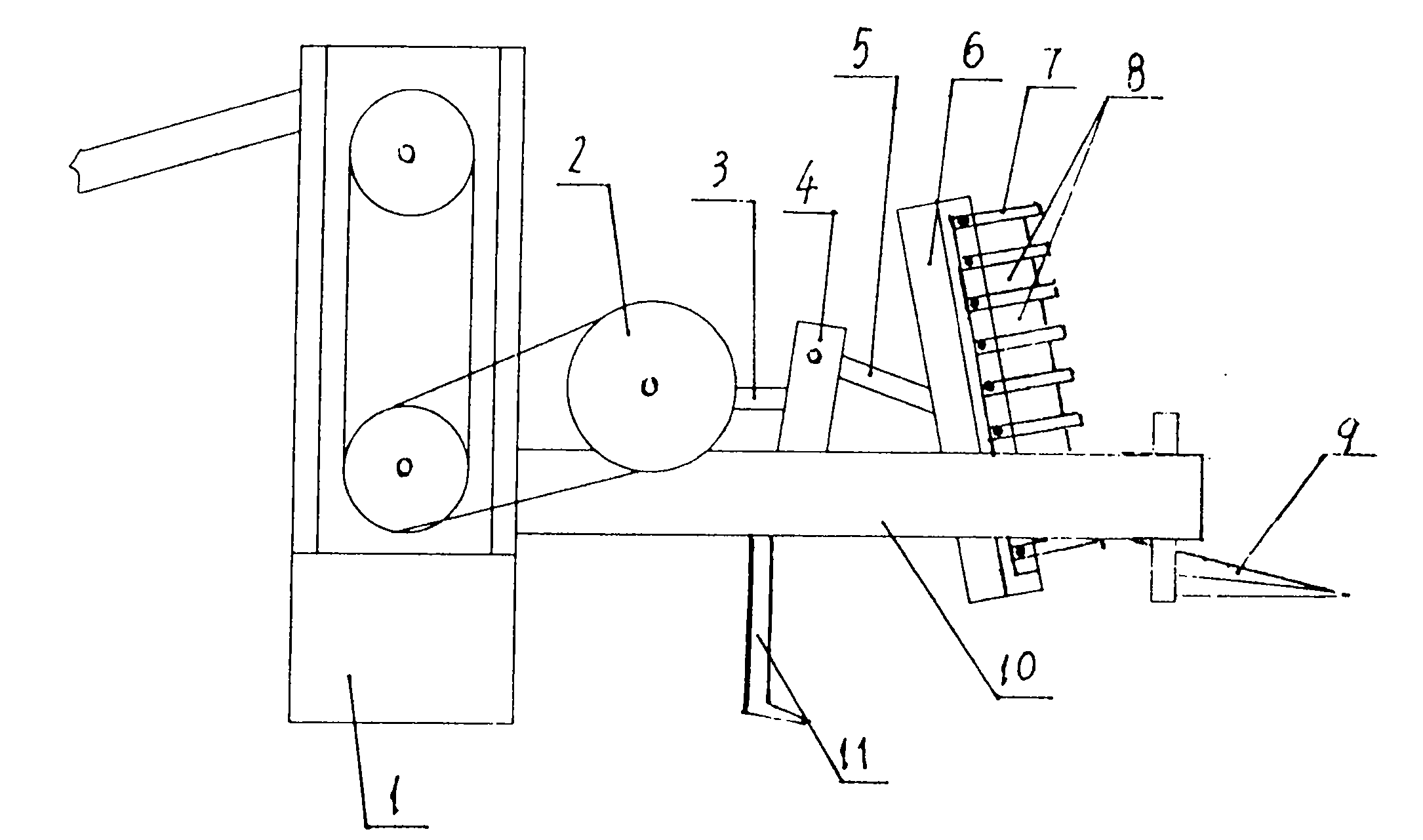

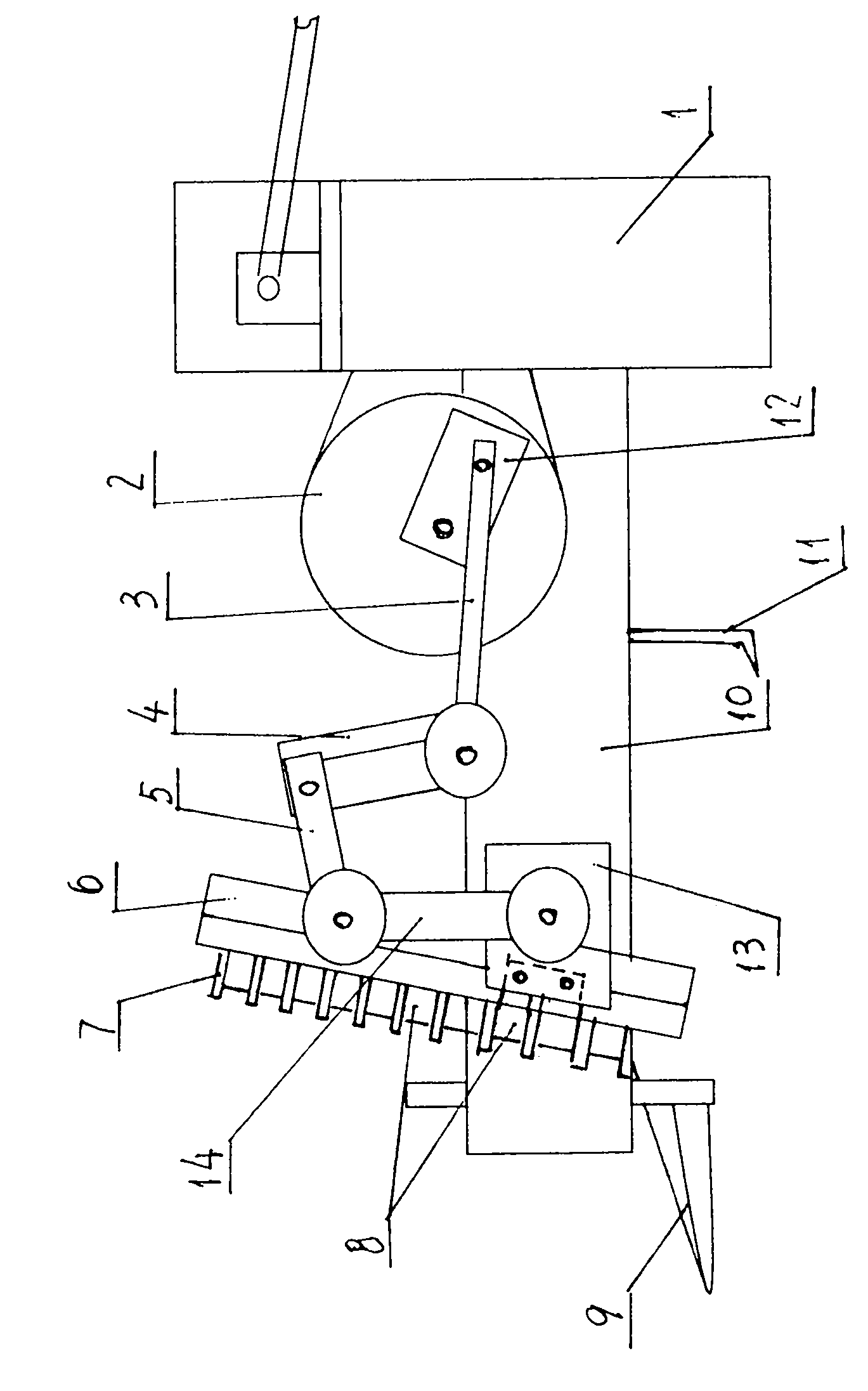

[0010] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. The vine breaking mechanism of the miscellaneous bean pulling machine includes a miscellaneous bean lifting machine frame 1, a longitudinal beam 10 is fixedly installed on the front side of the miscellaneous bean pulling machine frame 1, and the longitudinal beam 10 is sequentially arranged on the longitudinal beam 10 from front to back. Grain device 9, blade guard seat plate 6, rocking bar seat plate 4 and drive sprocket 2, wherein crop divider 9 can be adjusted up and down on the longitudinal beam 10, and blade guard seat plate 6 and rocking bar seat The plate 4 is fixed on the longitudinal beam 10, and the driving sprocket 2 is rotatably installed on the longitudinal beam 10; the eccentric wheel 12 is coaxially fixed on the side of the driving sprocket 2; the rocker 5 is hinged and installed swingably On the rocker seat plate 4; on the edge gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com