Coffeemaker brewing mechanism capable of automatically removing residues

A coffee machine and automatic technology, applied in kitchen utensils, household utensils, beverage preparation devices, etc., can solve the problems of limited application of filter bags, high cost, complex structure, etc., and achieve the effect of simple and reasonable structure, low cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the drawings and embodiments.

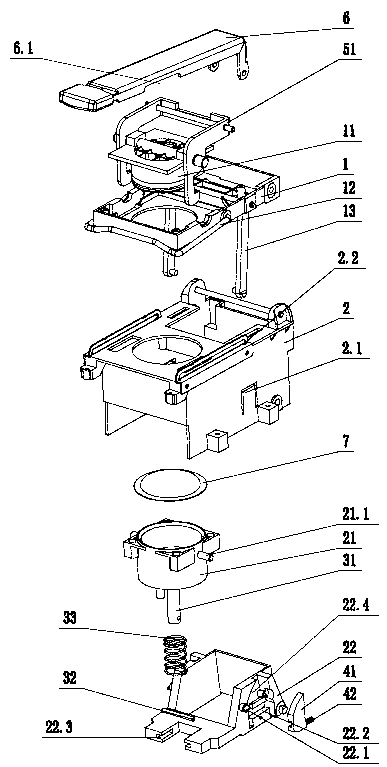

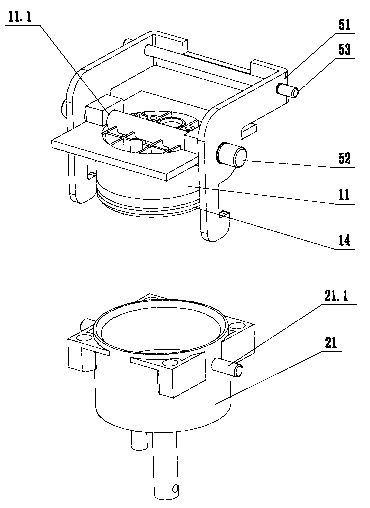

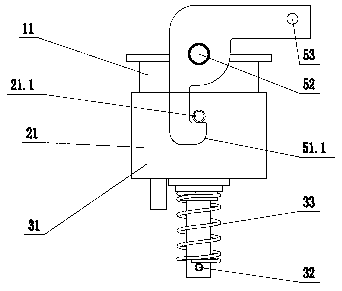

[0025] See Figure 1-Figure 8 , A coffee machine brewing mechanism with automatic slag removal, comprising an upper cover 1 and a base 2 that are hingedly matched. The upper cover 1 is provided with a brewing head 11, a slag scraping rod 12 and a connecting rod 13, and the base 2 is provided with a funnel 21. Rotating bracket 22 and chute 2.2. The funnel 21 is fitted with a push rod 31; the push rod 31 is slidably arranged up and down and connected to the rotating support 22 to form a crank connecting rod mechanism. The rotating support 22 is connected to the upper through the connecting rod 13 The cover 1 is connected to achieve linkage; the upper cover 1 flips up and down and cooperates with the rotating bracket 22 and the push rod 31, and at the same time drives the slag scraping rod 12 to slide back and forth in the chute 2.2.

[0026] One end of the push rod 31 is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com