Frame type hydraulic clamping grid die-casting machine

A die-casting machine and grid pressure technology, which is applied in the field of frame-type hydraulic locking template grid die-casting machine, can solve the problems of increasing the weight of the die-casting machine, inaccurate voltage conversion, and many welding seams, so as to achieve convenient transportation and assembly and reduce maintenance frequency , the effect of large protective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

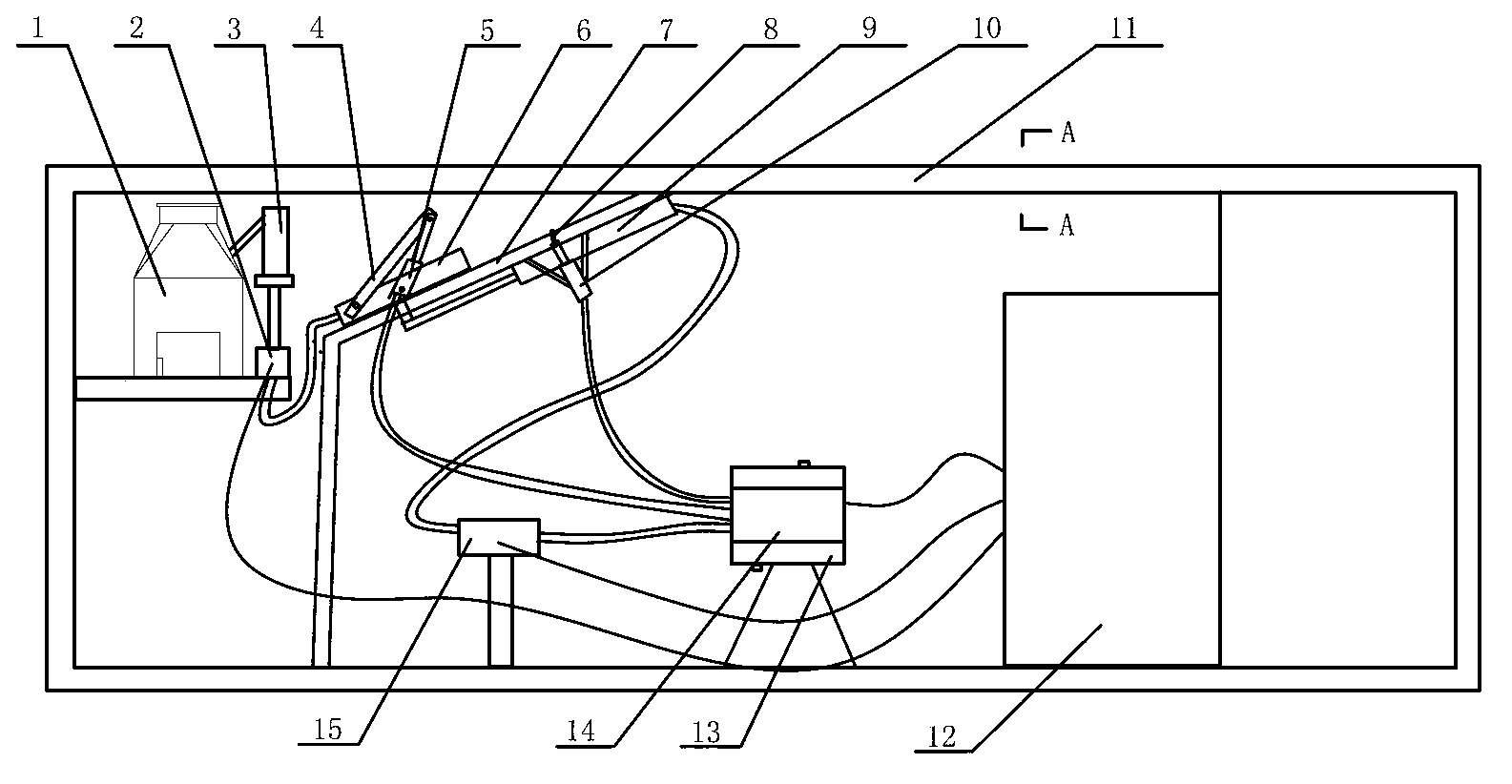

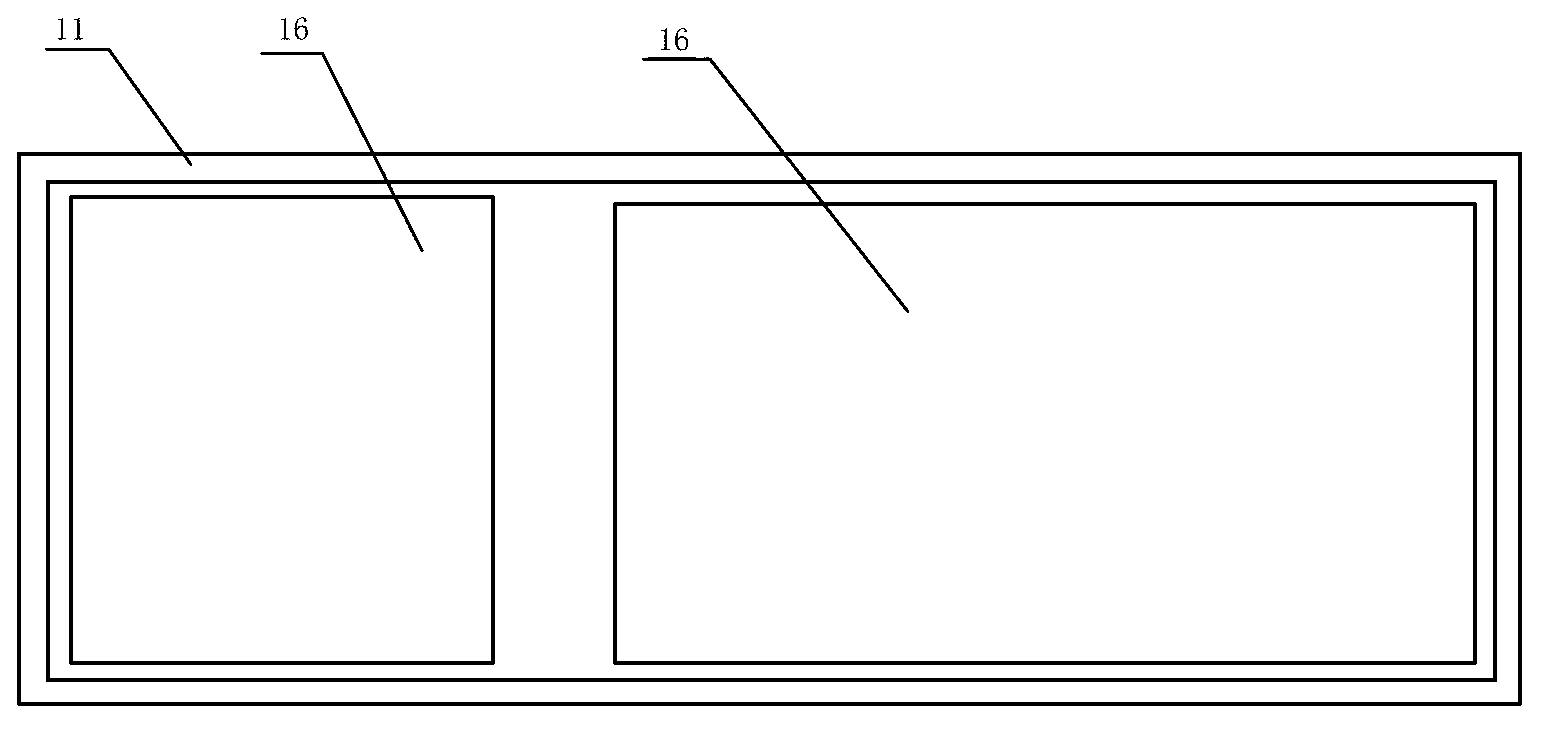

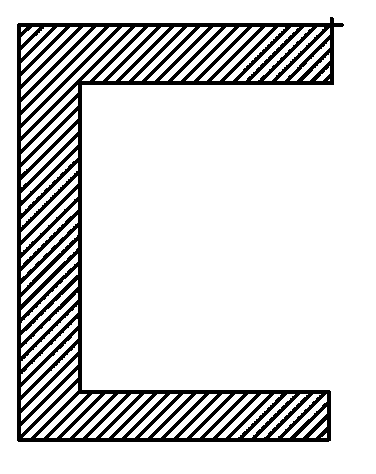

[0018] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0019] Such as Figure 1-Figure 3 As shown, the frame-type hydraulic lock formwork grid die-casting machine of the present invention includes a cuboid frame 11, a lead pot 1 is installed at the left end of the frame 11, the lead pot 1 is connected to the lead liquid pump 3, and the lead liquid pump 3 is connected to the die-casting machine. Machine 2, guide rail 7 is set on the right side of die-casting machine 2, mold 6 is installed on guide rail 7, guide rail 7, lead liquid pump 3 and die-casting machine 2 are all fixed on frame 11, proportional valve 15 is installed at the bottom of frame 11, and the mold is moved The oil cylinder 9 is connected to the hydraulic station 14 through the proportional valve 15, the mold-moving cylinder 9 is connected to the mold 6, the upper die 4 is installed on the mold 6, the clamping cylinder 5 is installed on the upper die 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com