Clamping and machining method for large thin-wall taper sleeves

A processing method and technology of tapered sleeves, which are applied in the field of clamping and processing of thin-walled tapered sleeves, can solve the problems of thin-walled long tapered sleeves that are difficult to clamp, difficult to control machining accuracy, and easy to deform, so as to improve the surface finish , Improve machining accuracy and reduce vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0033] The clamping and processing method of a large thin-walled tapered sleeve includes the following steps:

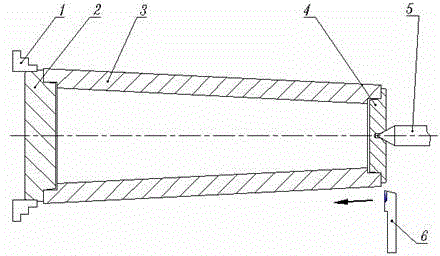

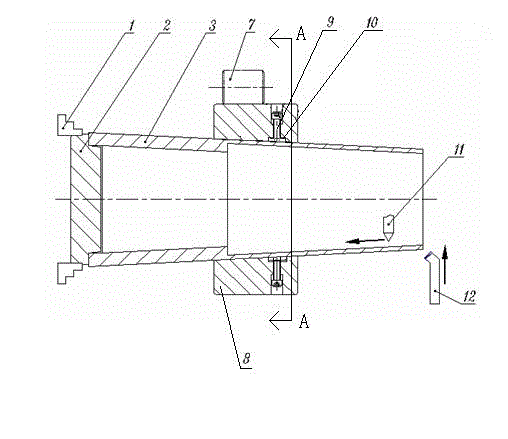

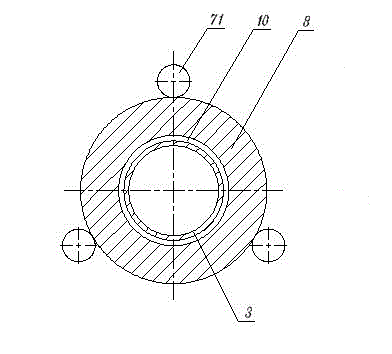

[0034] (1) First, clamp and turn the outer conical surface:

[0035] like figure 1 As shown, prepare the thin-walled conical sleeve blank to be processed. The blank is a hollow truncated cone. According to the inner diameter of the large end and the small end of the thin-walled conical sleeve to be processed, select the large-end stuffy cover with seam design 2 and the small-end stuffy cover 4, the two ends of the thin-walled tapered sleeve 3 to be processed are processed in advance to match the steps of the big-end stuffy cover and the small-end stuff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com