Cold drawing processing technology of rocker support rod of spinning frame

A processing technology and spinning frame technology, which is applied in the field of cradle rod forming of spinning frame, can solve the problems of poor corrosion resistance of galvanizing, low material surface hardness, and knife lines on the processing surface, etc. Stabilizing, indentation-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

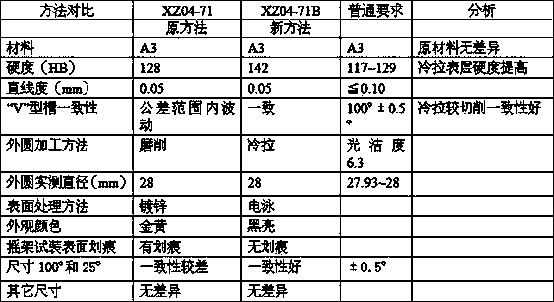

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A cold-drawing processing technology for the cradle rod of a spinning frame, comprising the following steps:

[0016] (1) The first cold-drawn V-groove: Put the Φ32 A3 steel bar in the double-roller cold-drawing die for the first cold-drawn V-shaped groove. Through the first cold-drawing V-shaped groove treatment, a V-shaped groove with a groove depth of 5.5mm on the outer circle of the round bar blank and a formed 100o is obtained;

[0017] (2) The first annealing: the first annealing is performed after the first cold drawing V-groove treatment, the annealing temperature is 680oC, and the annealing time is 4 hours;

[0018] (3) The shape of the second rough drawing: choose the cold drawing die with an inner diameter of Φ30 mm, a 5.5mm inner circle top, and a 100o protrusion for the second rough drawing shape treatment; obtain an outer diameter of Φ30mm and a groove depth of 5.5mm , The cradle strut a of the V-shaped groove forming 100o;

[0019] (4) The second anneal...

Embodiment 2

[0026] A cold-drawing processing technology for the cradle rod of a spinning frame, comprising the following steps:

[0027] (1) The first cold-drawn V-groove: Put the Φ32 A3 steel bar in the double-roller cold-drawing die for the first cold-drawn V-shaped groove. Through the first cold-drawing V-shaped groove treatment, a V-shaped groove with a groove depth of 5.5mm on the outer circle of the round bar blank and a formed 100o is obtained;

[0028] (2) The first annealing: the first annealing is performed after the first cold drawing V-groove treatment, the annealing temperature is 680oC, and the annealing time is 4 hours;

[0029] (3) The shape of the second rough drawing: choose the cold drawing die with an inner diameter of Φ30 mm, a 5.5mm inner circle top, and a 100o protrusion for the second rough drawing shape treatment; obtain an outer diameter of Φ30mm and a groove depth of 5.5mm , The cradle strut a of the V-shaped groove forming 100o;

[0030] (4) The second anneal...

Embodiment 3

[0037] A cold-drawing processing technology for the cradle rod of a spinning frame, comprising the following steps:

[0038] (1) The first cold-drawn V-groove: Put the Φ32 A3 steel bar in the double-roller cold-drawing die for the first cold-drawn V-shaped groove. Through the first cold-drawing V-shaped groove treatment, a V-shaped groove with a groove depth of 5.5mm on the outer circle of the round bar blank and a formed 100o is obtained;

[0039] (2) The first annealing: the first annealing is performed after the first cold drawing V-groove treatment, the annealing temperature is 680oC, and the annealing time is 4 hours;

[0040] (3) The shape of the second rough drawing: choose the cold drawing die with an inner diameter of Φ30 mm, a 5.5mm inner circle top, and a 100o protrusion for the second rough drawing shape treatment; obtain an outer diameter of Φ30mm and a groove depth of 5.5mm , The cradle strut a of the V-shaped groove forming 100o;

[0041] (4) The second anneal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com