Bi-directional barb exiting sliding block mechanism

A technology of two-way barbs and sliders, applied in the field of slider mechanisms, can solve the problems of insufficient strength, unstable work, and low safety of the reverse small shifting block structure 42, and achieve simple structure, convenient processing and assembly, and not easy to wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

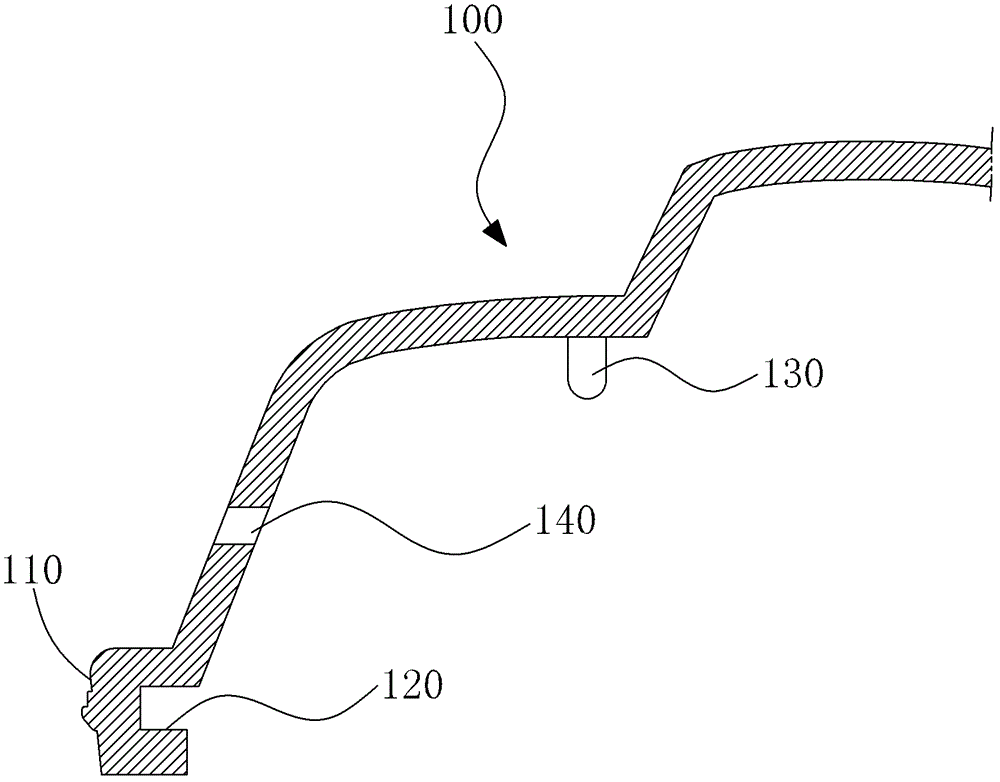

[0027] Please refer to 3, which shows a schematic cross-sectional view of a product with two-way barbs on the side. The product 100 has an outer barb 110 and an inner barb 120 on the side, a rib structure 130 on the inner top surface of the product 100, and a horizontal hole 140 on the side of the product.

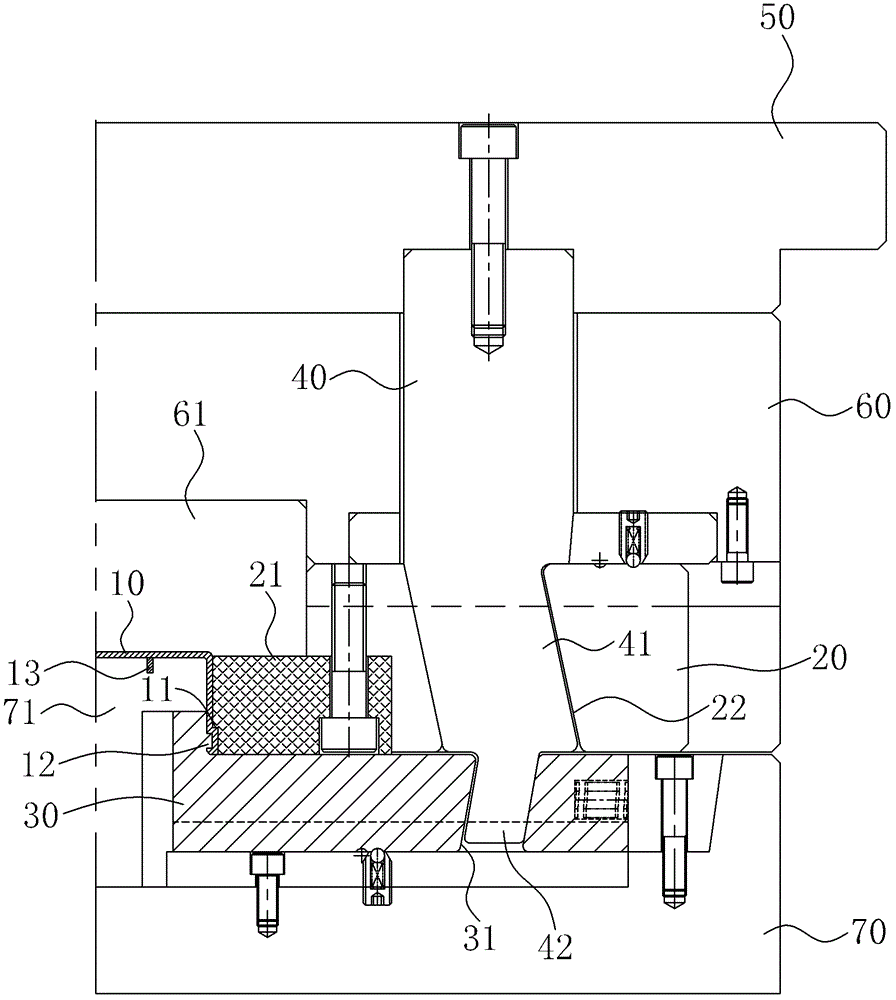

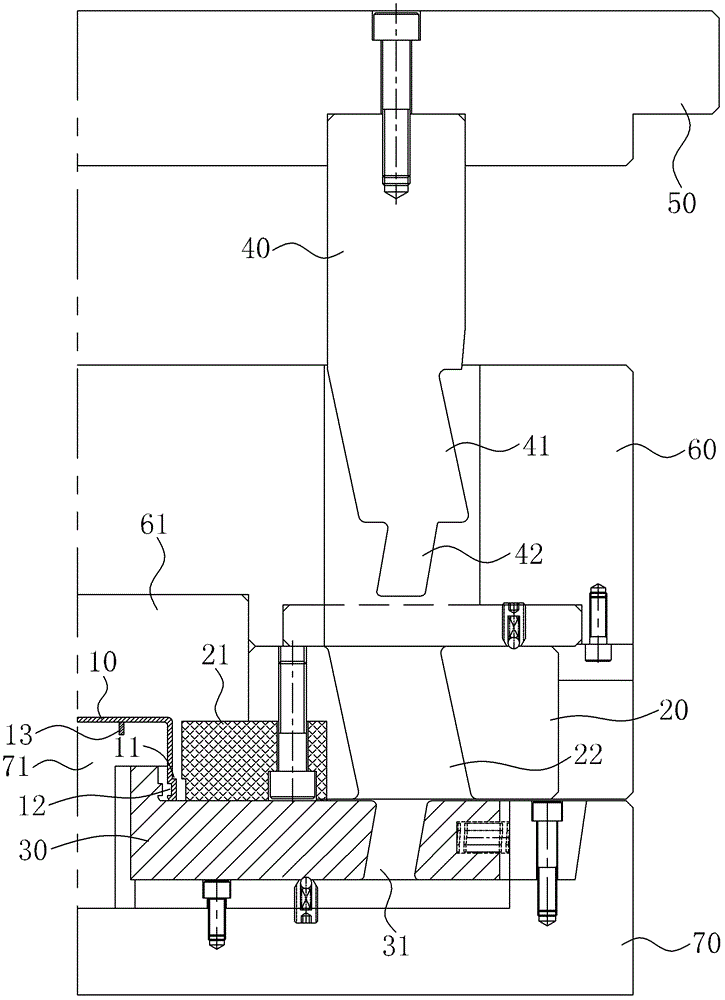

[0028] see Figure 4 to Figure 7 As shown, the two-way barb exit slider mechanism of the present invention is applied in a mold for molding the product 100. The mold includes an upper fixing plate 200, a female template 300, a female mold core 310, a male template 400, and a male mold core 410 , is characterized in that the two-way barb exit slider mechanism of the present invention includes:

[0029] An outer slider 600, which is slidably arranged on the master template 300, its front end extends into the cavity t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com