Construction machinery and its supporting devices

A technology of engineering machinery and supporting devices, applied in cranes, transportation and packaging, vehicle maintenance, etc., can solve problems such as the large space occupied by the swing outrigger 4, difficulty in arranging the swing outrigger 4, and the limitation of the distance of the movable outrigger, and achieve structural Compactness, improved vehicle stability, and reduced vehicle weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

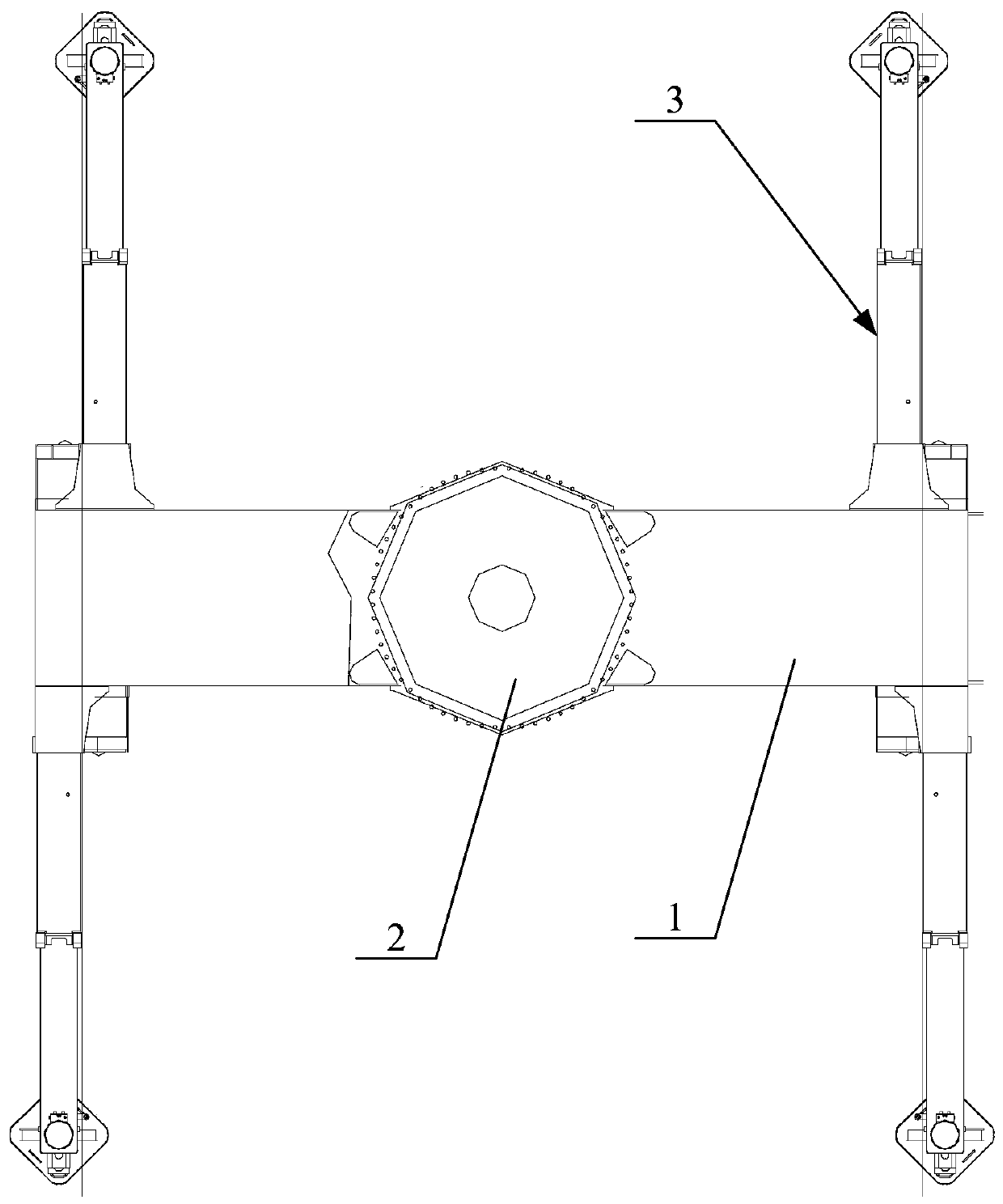

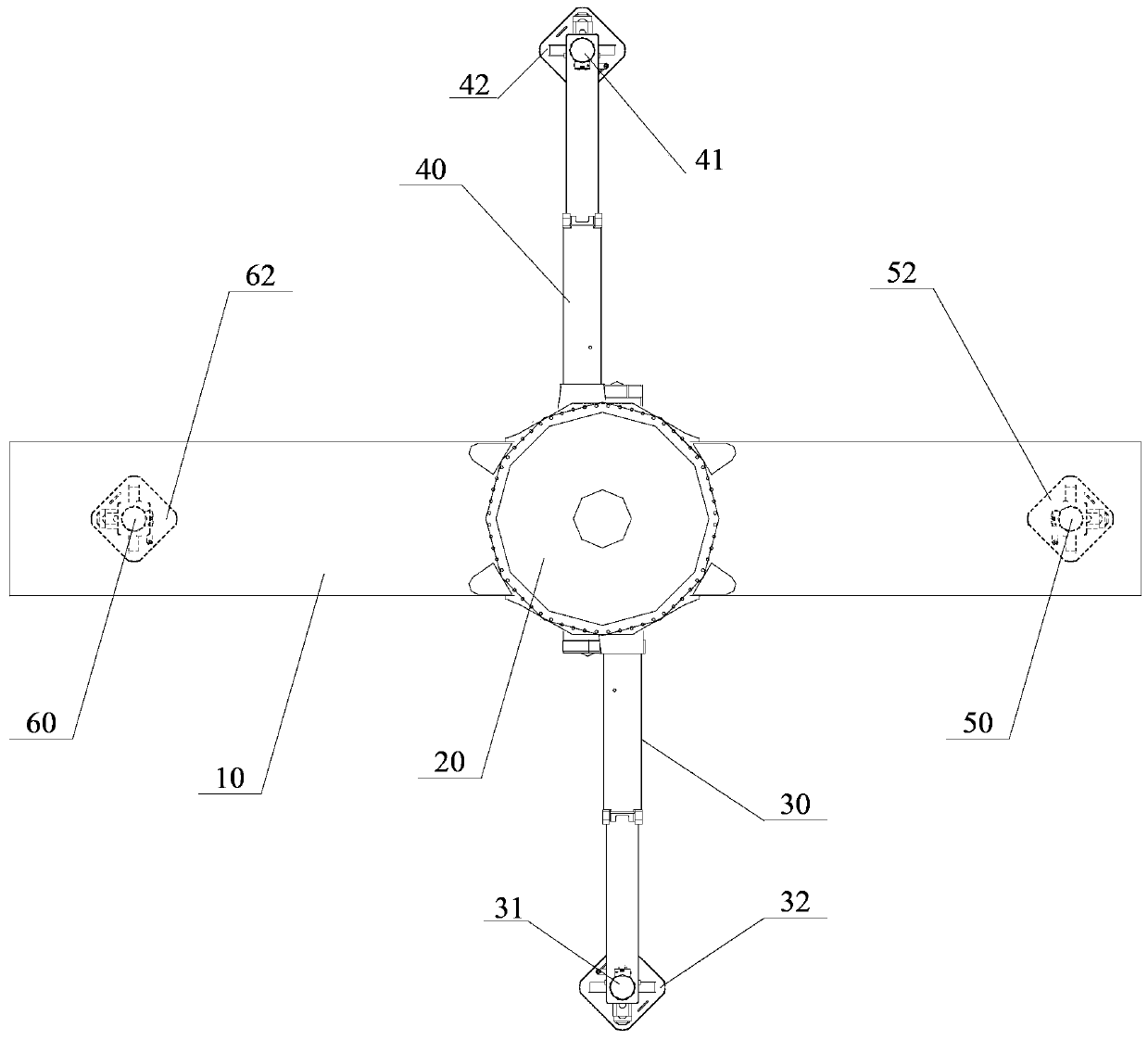

[0050] refer to image 3 , which shows an implementation structure of a support device for construction machinery, the support device includes: a first movable outrigger, a second movable outrigger, and at least one supporting mechanism. Wherein, the first movable outrigger is arranged at a position corresponding to the center of rotation 20 on the frame 10 of the engineering machine, and is telescopically arranged toward the right side of the frame 10 . The extended position of the first movable leg corresponds to the center of rotation 20 on the vehicle frame 10 . The second movable outrigger is disposed at a position corresponding to the center of rotation 20 on the vehicle frame 10 , and is telescopically disposed toward the left side of the vehicle frame 10 . At least one supporting mechanism is arranged on the vehicle frame 10 . The extended position of the second movable leg corresponds to the center of rotation 20 on the vehicle frame 10 .

[0051] Optionally, in th...

no. 2 example

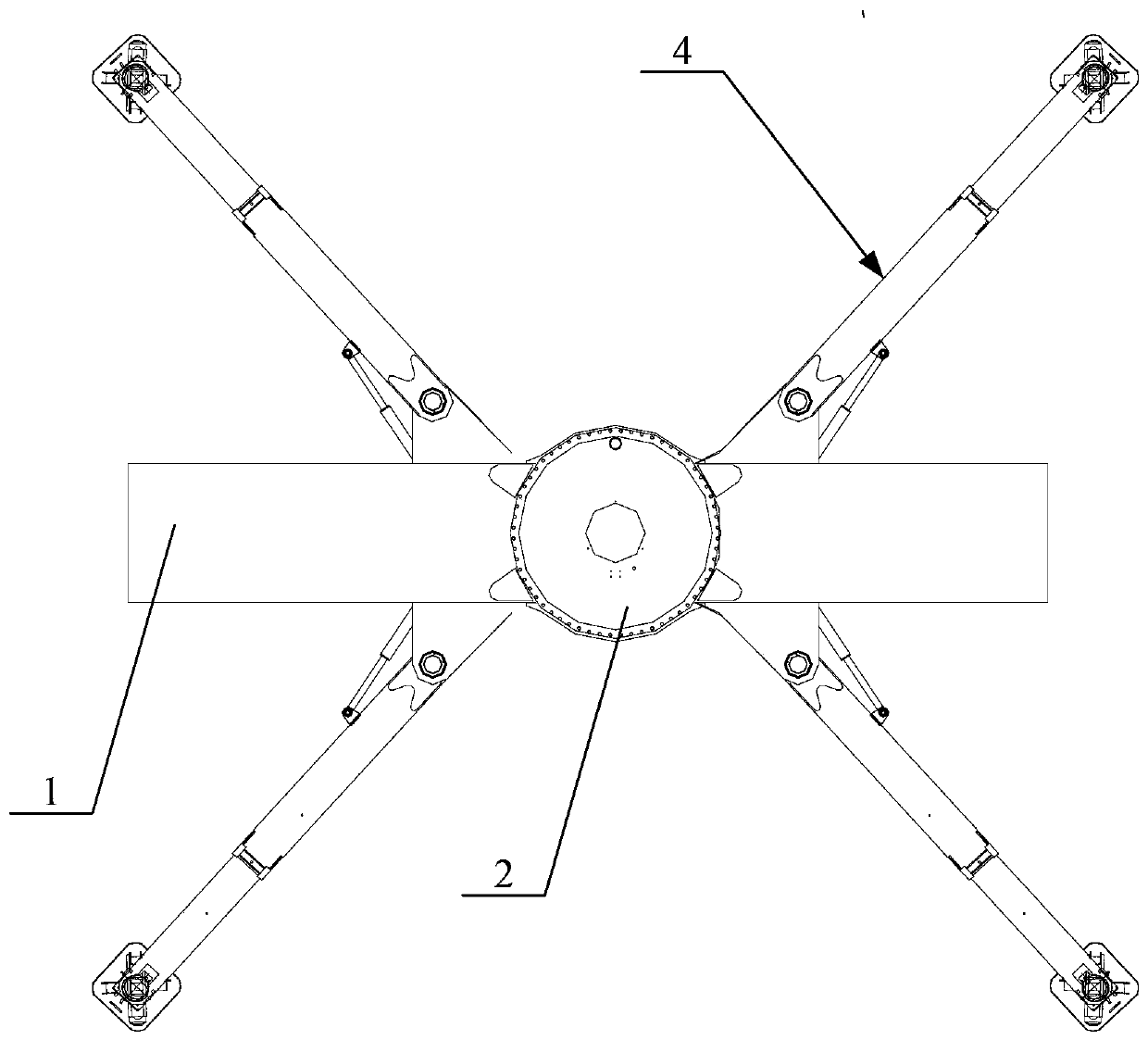

[0073] refer to Figure 4 , which shows another implementation structure of a support device for construction machinery, the support device includes: a first movable outrigger, a second movable outrigger, a third movable outrigger and a fourth supporting mechanism. Wherein, the first movable outrigger is arranged on one side of the vehicle frame 10 of the construction machine, and its protruding position corresponds to the rotation center 20 on the vehicle frame 10 . The second movable leg is arranged on the other side of the vehicle frame 10 , and its extended position corresponds to the center of rotation 20 on the vehicle frame 10 . The third movable outrigger is arranged at the rear of the vehicle frame 10 , and the fourth supporting mechanism is arranged at the front of the vehicle frame 10 .

[0074] In this embodiment, for some models whose outrigger span needs to be increased, a movable outrigger can be added at the rear of the vehicle frame to meet the requirement fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com