Debugging method of railway signal maintenance system

A technology of railway signal maintenance and debugging method, applied in railway signal and safety, etc., can solve the problems of manual recording not meeting the engineering debugging requirements of railway signal maintenance system, too many interfaces, misrecording, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

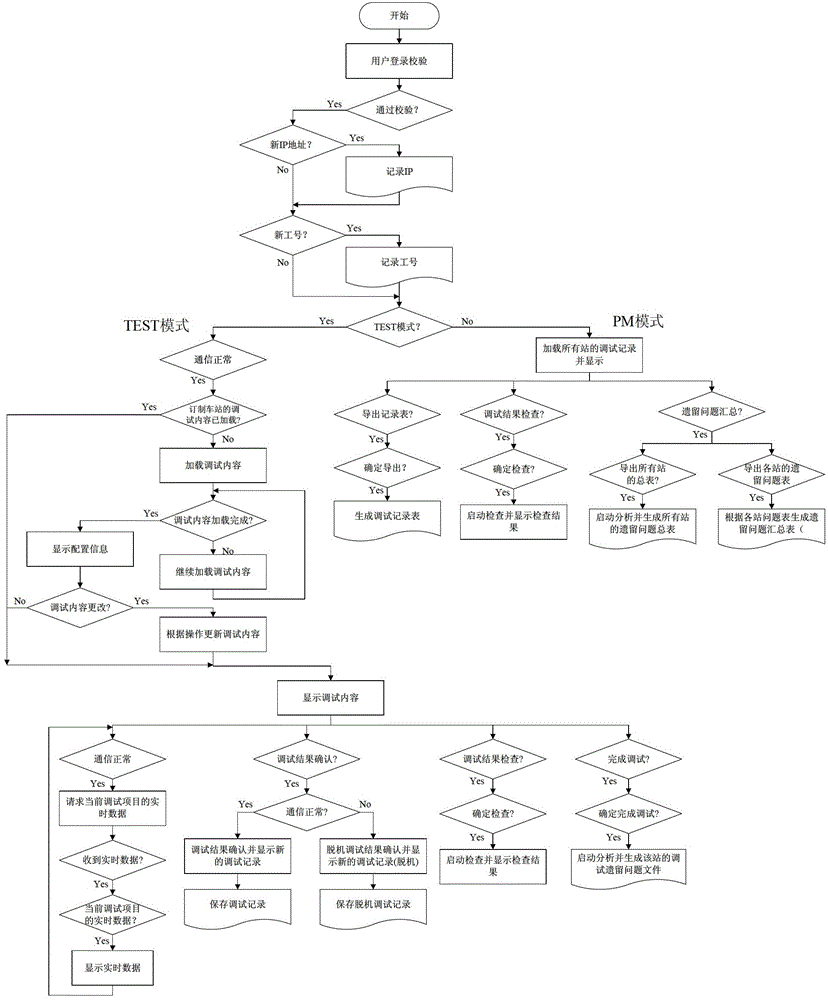

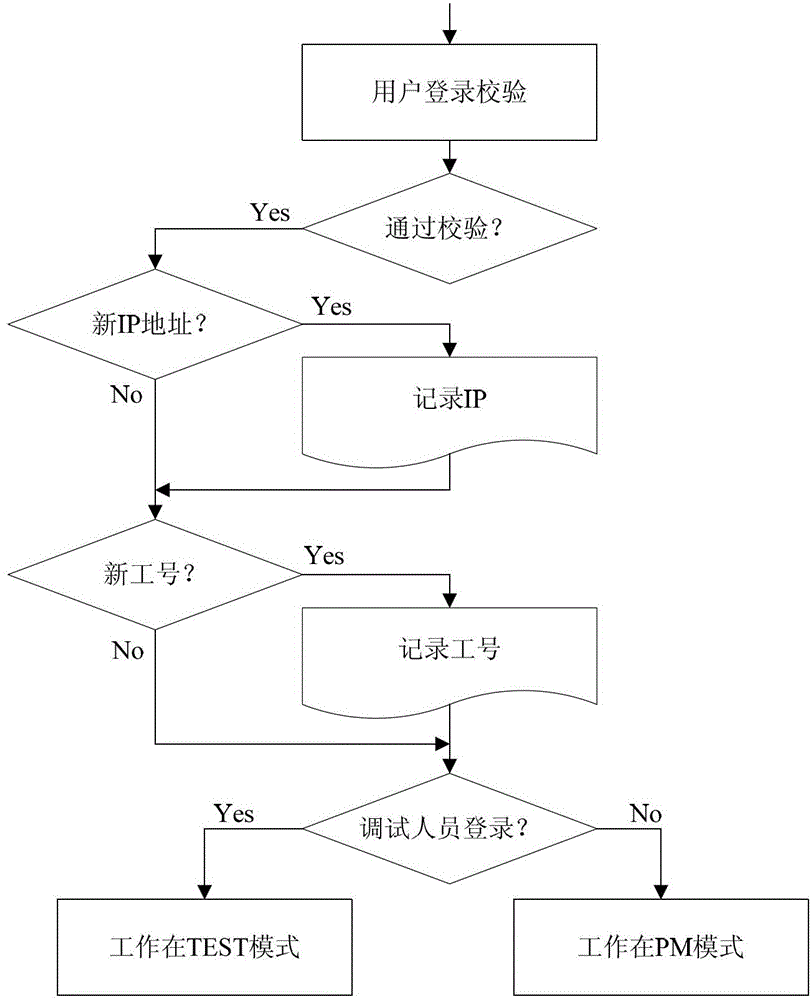

[0107] like figure 1 As shown, a debugging method of railway signal maintenance system, the method is based on the debugging record data of a single monitoring station, can obtain the debugging content of the station according to the standard debugging procedures, real-time debugging data, record the debugging information, and provide the confirmation of the debugging results , debugging result inspection, analysis of remaining problems, and finally a debugging record sheet and a remaining problem recording table that meet the requirements of standard debugging procedures and specifications can be generated; the specific process of the debugging method is as follows:

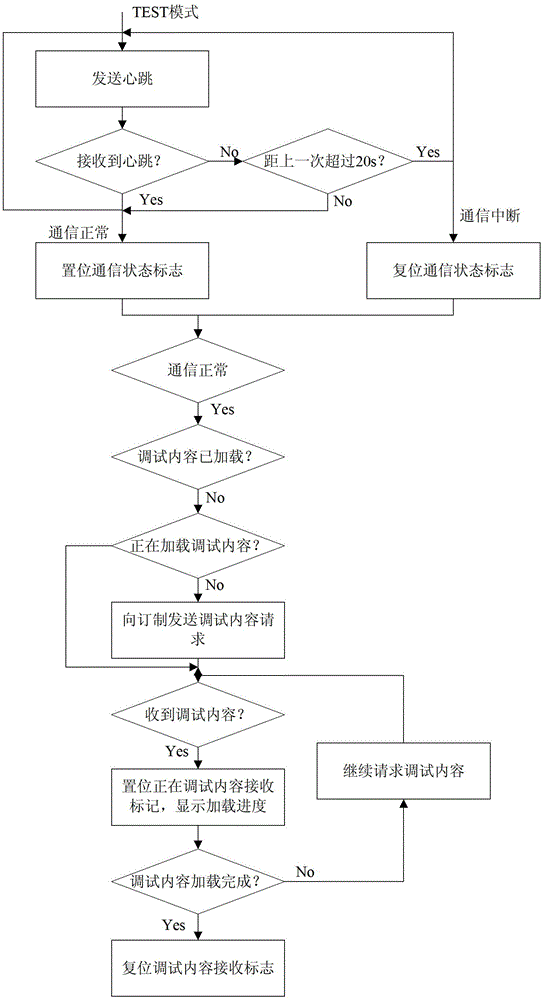

[0108] 1) Enter TEST mode;

[0109] 2) Interact with the customized signal centralized monitoring station to obtain real-time communication status, and automatically start the loading of debugging content when the communication is normal;

[0110] 3) Load the debugging content and display the loading progress; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com