Pallet box stacking structure

A pallet box, stacking technology, applied in rigid containers, containers, packaging and other directions, can solve the problems of difficult stacking guidance, damage to the box cover, high cost, and achieve the effects of convenient forklift operation, reliable position limit and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing.

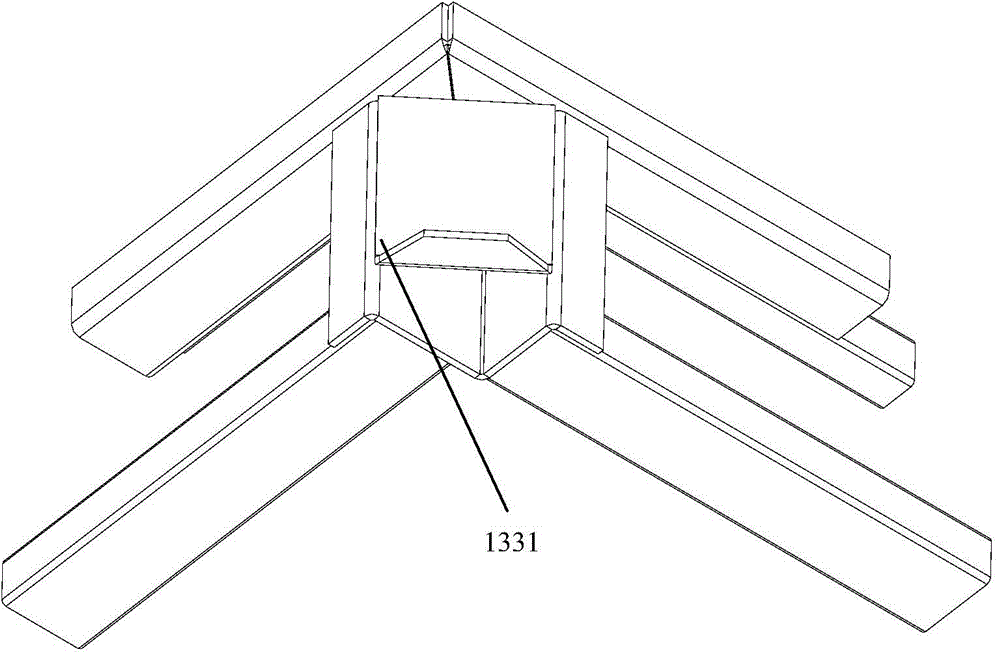

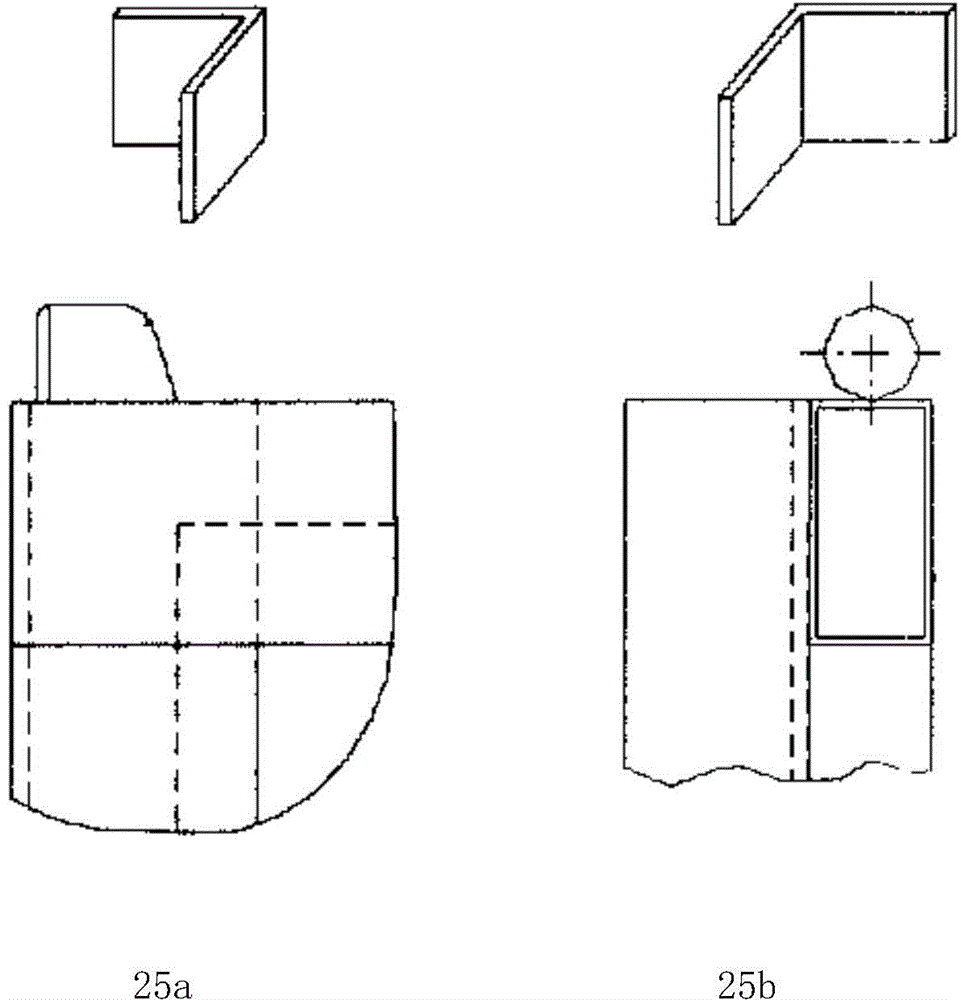

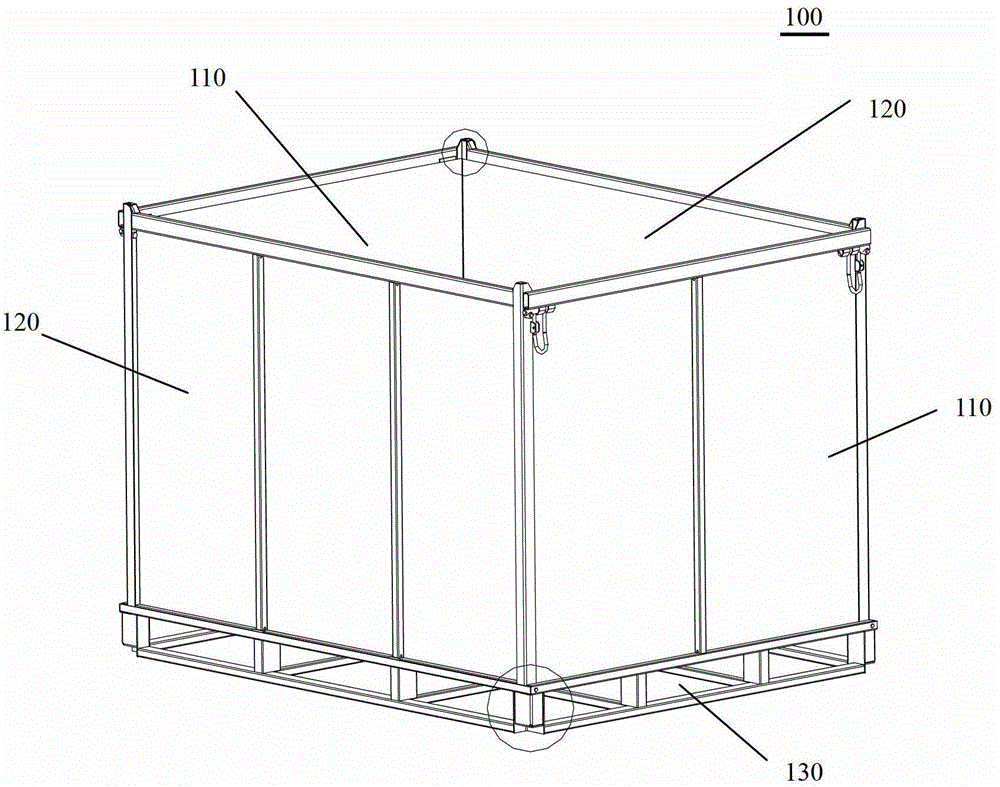

[0049] Such as Figure 1-15As shown, the pallet box is composed of a chassis 130, two end walls 110 and two side walls 120. A stacking space 134 is arranged at the four corners of the bottom of the chassis 130. The stacking space 134 is adapted to the pallet box limiter below. When two pallet boxes are stacked together, there are no side-by-side parts, which saves space and avoids interference. Stacking space 134 is formed by chassis corner post 132, and the cross-section of chassis corner post 132 is L-shaped, and the two supporting arms of L shape are corner post uprights 1321, 1322, and the space between corner post uprights forms cuboid stacking space 134 . In order to increase the rigidity of the chassis corner post 132, two bent side plates 1323 can be added to improve the rigidity of the chassis corner post, as Figure 23 shown.

[0050] The limiting device of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com