Liquid crystal display panel packing box and waterproof structure thereof

A liquid crystal panel and waterproof structure technology, which is applied in packaging, transportation and packaging, and packaging of vulnerable items. It can solve the problems of heavy weight and inconvenient handling of the integrated packaging box, and achieve the effect of reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

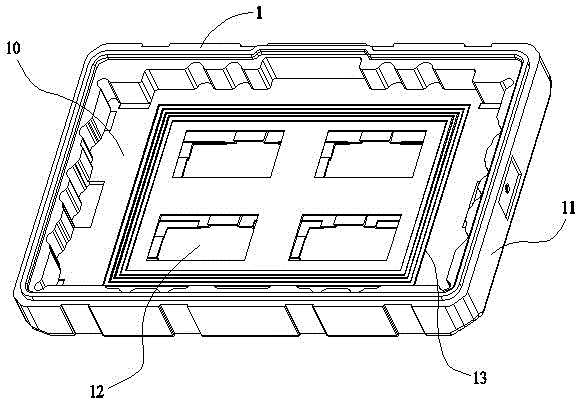

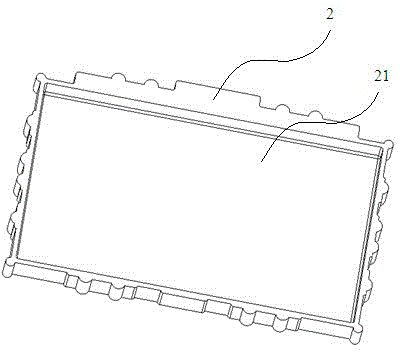

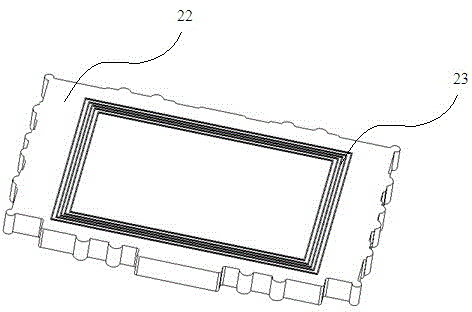

[0032] Please refer to Fig. 1, the embodiment of the present invention provides a liquid crystal panel packaging box 1, including a rectangular bottom plate 10 and a side wall 11 arranged along the edge of the bottom plate 10, the bottom plate 10 and the side wall 11 together form an accommodation space for placing LCD panel. At the same time, in order to prevent the liquid crystal panel from colliding with the bottom plate 10 and being damaged during transportation, the spacer 2 is arranged on the bottom plate 10, and then the liquid crystal panel is placed on the spacer 2, and the spacer 2 acts as a buffer. effect. The shape of the edge of the spacer 2 is adapted to the side wall 11 so that the spacer 2 will not become loose after being placed on the bottom plate 10 . 2 and 3 are schematic diagrams of the top surface 21 and the bottom surface 22 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com