Filling machine

A technology of filling machine and transmission device, which is applied in the field of bottle feeding screw mechanism, which can solve the problems of reducing work efficiency, increasing production cost, and being unable to adjust the vertical height and horizontal position of the bottle feeding screw, so as to improve labor efficiency and bottle feeding The effect of orderly operation and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

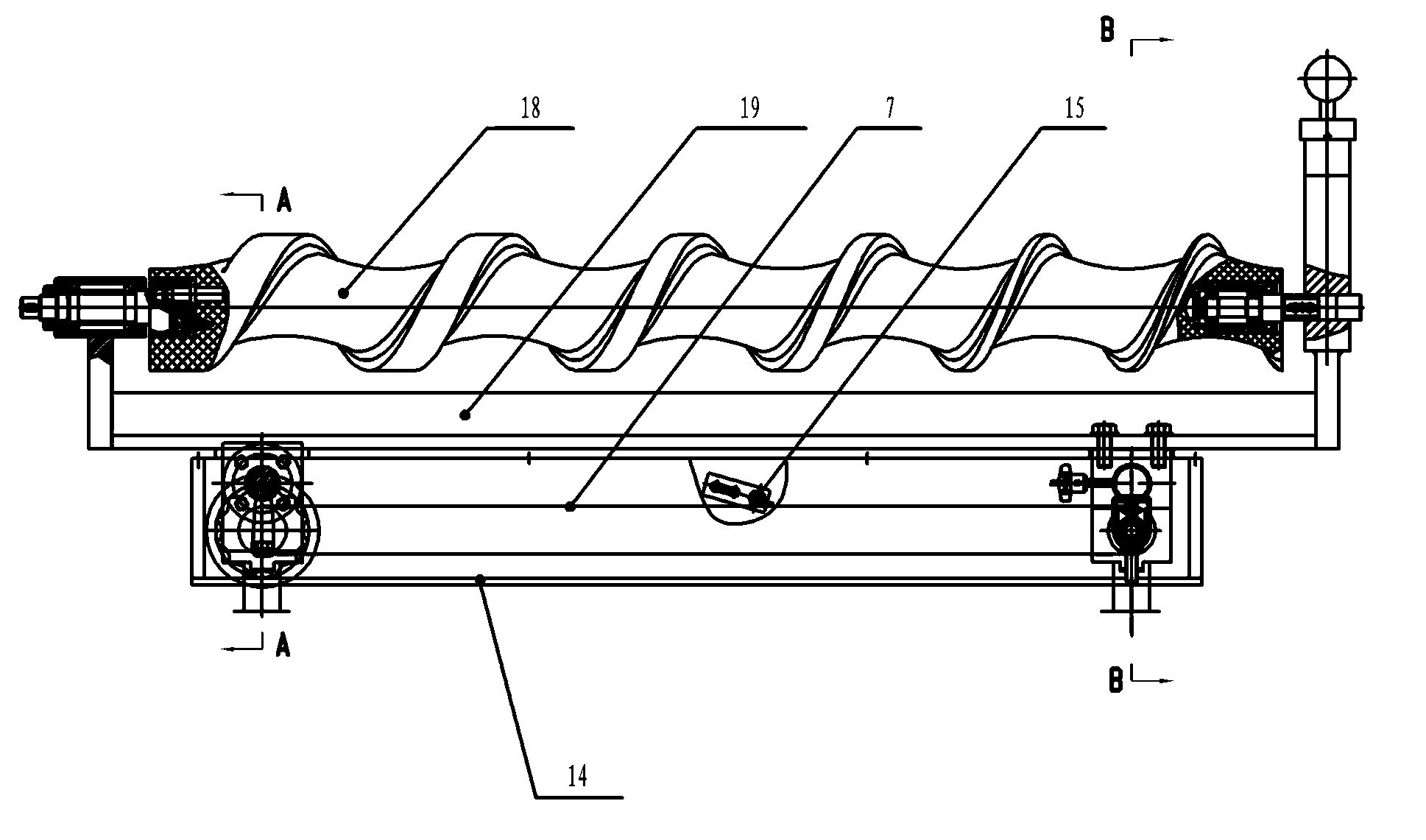

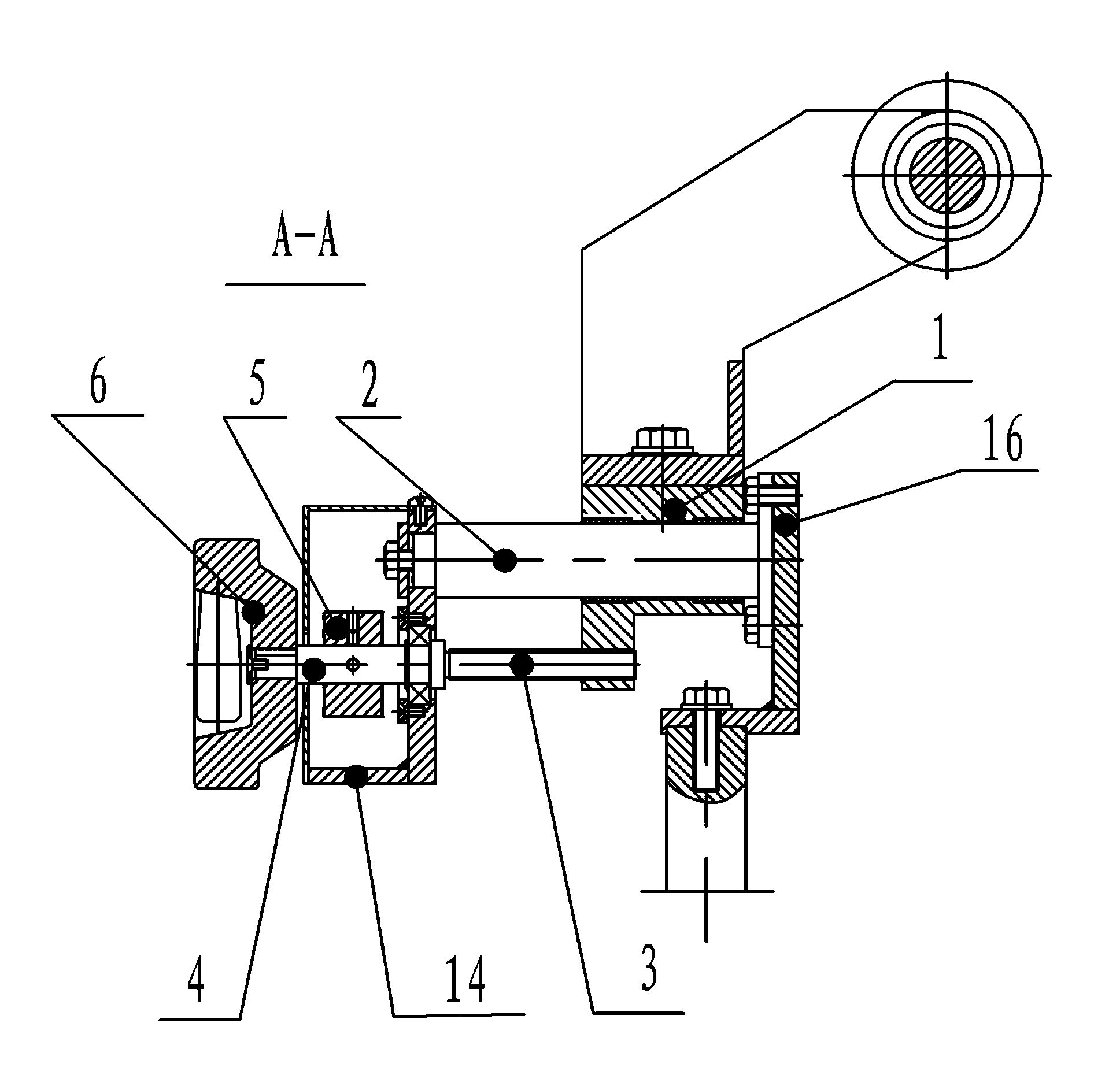

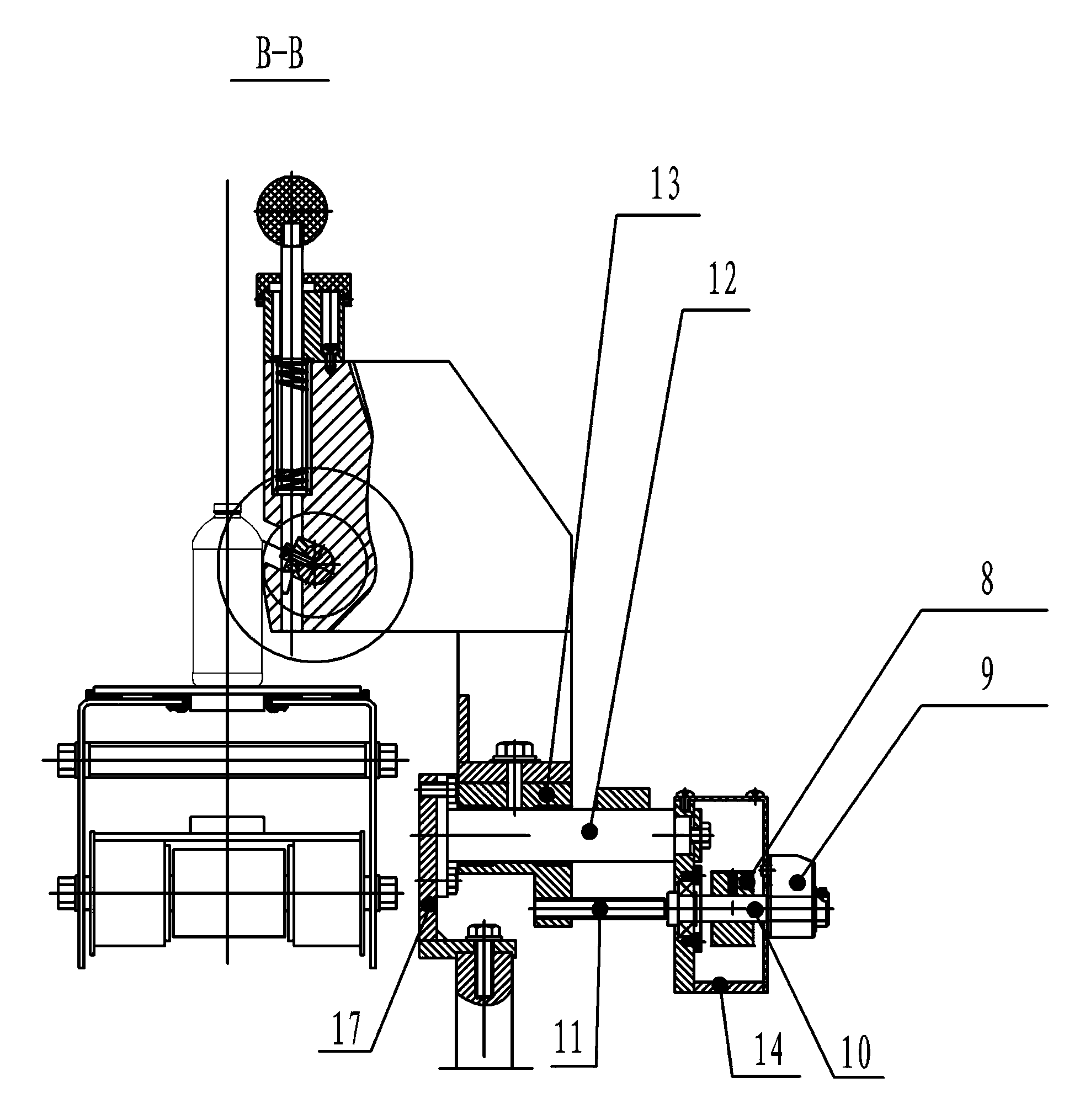

[0010] Embodiment 1: as Figure 1 to Figure 3 As shown, a filling machine includes a bottle feeding screw 18, the bottle feeding screw 18 is installed on a support frame 19, the support frame 19 is fixed on the left sliding seat 1 and the right sliding seat 13, and the left sliding seat 1 is installed on the left guide On the rod 2, the extended part of the left sliding seat 1 is connected to one end of the left rotating screw 3, and the other end of the left rotating screw 3 is fixed to the left rotating shaft 4, and the driving wheel 5 is fixed on the left rotating shaft 4, and one end of the left rotating shaft 4 is connected to control the left rotating shaft 4 The rotating adjustment hand wheel 6, the driving wheel 5 is connected with the driven wheel 8 through the synchronous belt 7 or the chain, the driven wheel 8 is installed and fixed on the right rotating shaft 10, the right rotating shaft 10 is connected to one end of the right rotating screw rod 11, and the position...

Embodiment 2

[0013] Embodiment 2: In the filling machine, the support frame 19 equipped with the bottle feeding screw 18 is fixed on the sliding seat, the sliding seat is installed on the guide rod, the extended part of the sliding seat is installed on the flat surface of the rack, and the rack Mesh with the gear, and the gear is connected with the stepper motor. The horizontal position adjustment mechanism of the bottle-feeding screw is placed in the middle of the bottle-feeding screw support frame. The stepper motor controls the gear rotation to drive the rack to slide horizontally, so that the rack drives the sliding seat to slide horizontally, and then the sliding seat drives the support frame 19 to slide horizontally. To complete the bottle-feeding screw rod 18 horizontal position adjustment actions.

Embodiment 3

[0014] Embodiment 3: The sliding seat is installed on the guide rod, the extended part of the sliding seat is connected with the rotating screw, and the device for controlling the rotation of the screw is a stepping motor. The horizontal position adjustment mechanism of the bottle feeding screw is placed in the middle of the bottle feeding screw support frame, and the stepping motor or adjusting handwheel works to drive the rotating screw to rotate, and the rotating screw screw drive controls the sliding seat to slide horizontally on the guide rod, thereby driving the support frame 19 slides horizontally, and then drives the bottle-entry screw rod 18 to move horizontally to complete the horizontal position adjustment action.

[0015] The device for controlling the rotation of the left shaft 4, the gear and the rotating screw respectively is the adjusting hand wheel 6 or a stepping motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com