Method for preparing non-rare-earth high-magnetism permanent magnetic ferrite material

A permanent magnet ferrite, high magnetic technology, applied in the field of preparation of permanent magnet ferrite materials, can solve problems such as simultaneous attainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

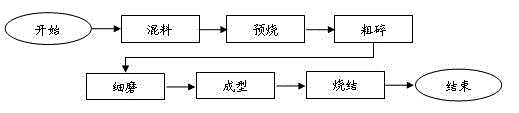

[0031] The following is the first embodiment of preparing non-rare earth high magnetic permanent magnet ferrite material, including the following steps:

[0032] Mixing process: After mixing the calcined materials, use a wet ball mill for 1-10 hours of mixing and crushing treatment. After the slurry is dried, the specific surface area is 1-10m 2 / g;

[0033] Among them, the calcined material includes main and auxiliary components and grinding aids, and the main component is Fe 2 o 3 and SrCO 3 , the molar ratio is 6.15; the secondary component is CaCO 3 : 0.3wt%~0.5wt%; SiO 2 :0.2wt%~0.4wt%; Al 2 o 3 : 1.0wt%~3.0wt%; additionally add grinding aid 1.0wt%;

[0034] Pre-calcination process: pre-calcine the mixture obtained in the mixing process in the air, the pre-calcination temperature is 1180 ° C, and the holding time is 3 hours, and six parts of the primary pre-calcination are obtained as comparative examples, respectively numbered A-1 and A-2 , A-3, B-1, B-2, B-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com