Multi-jet-needle combination device for weft insertion mechanisms of water-jet looms

A technology of water jet loom and weft insertion mechanism, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of difficulty in arranging spray needles, easy deformation of spray needle combination devices, and pressure loss, etc. Water pressure loss, minimal design allowable space close, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

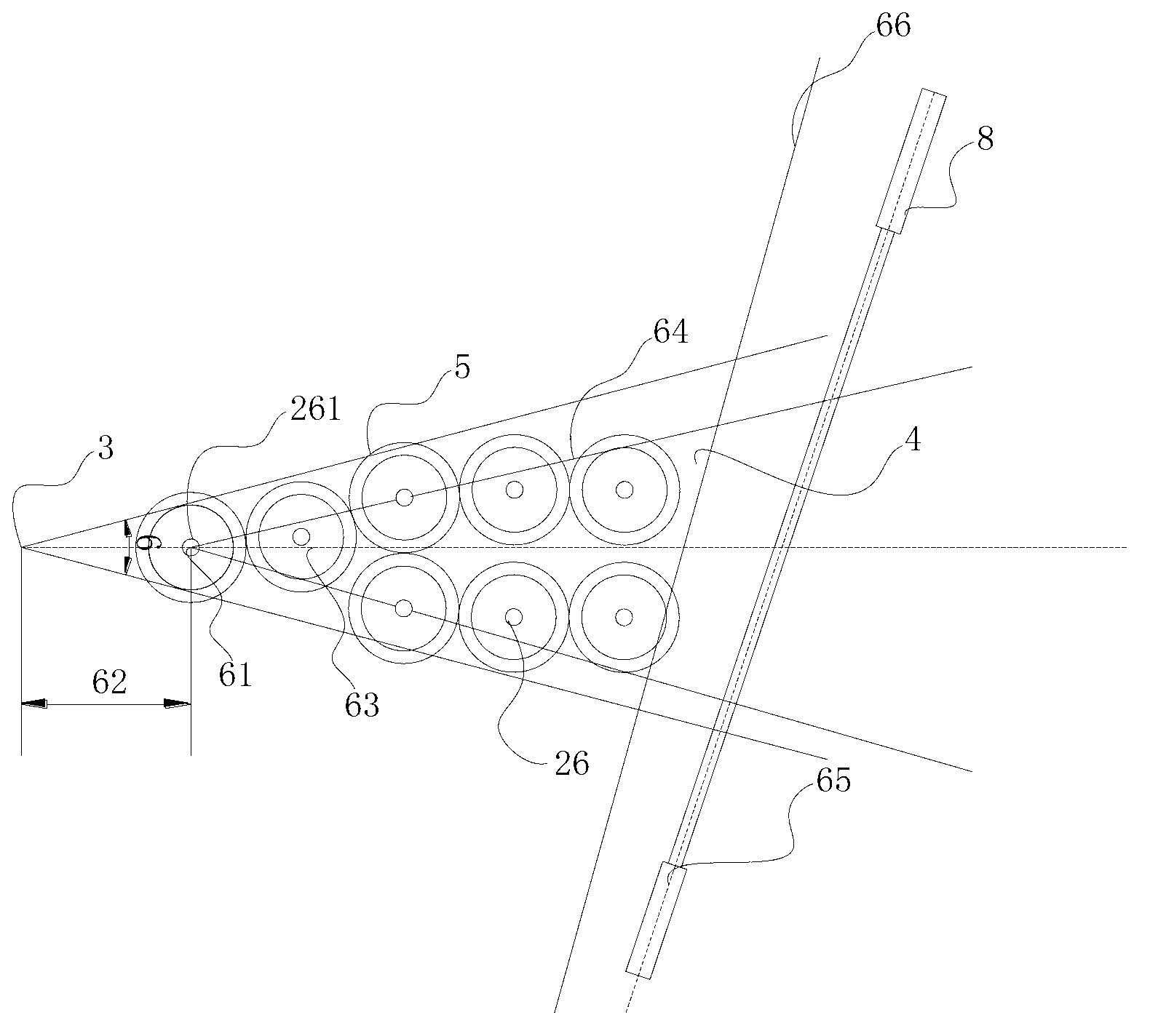

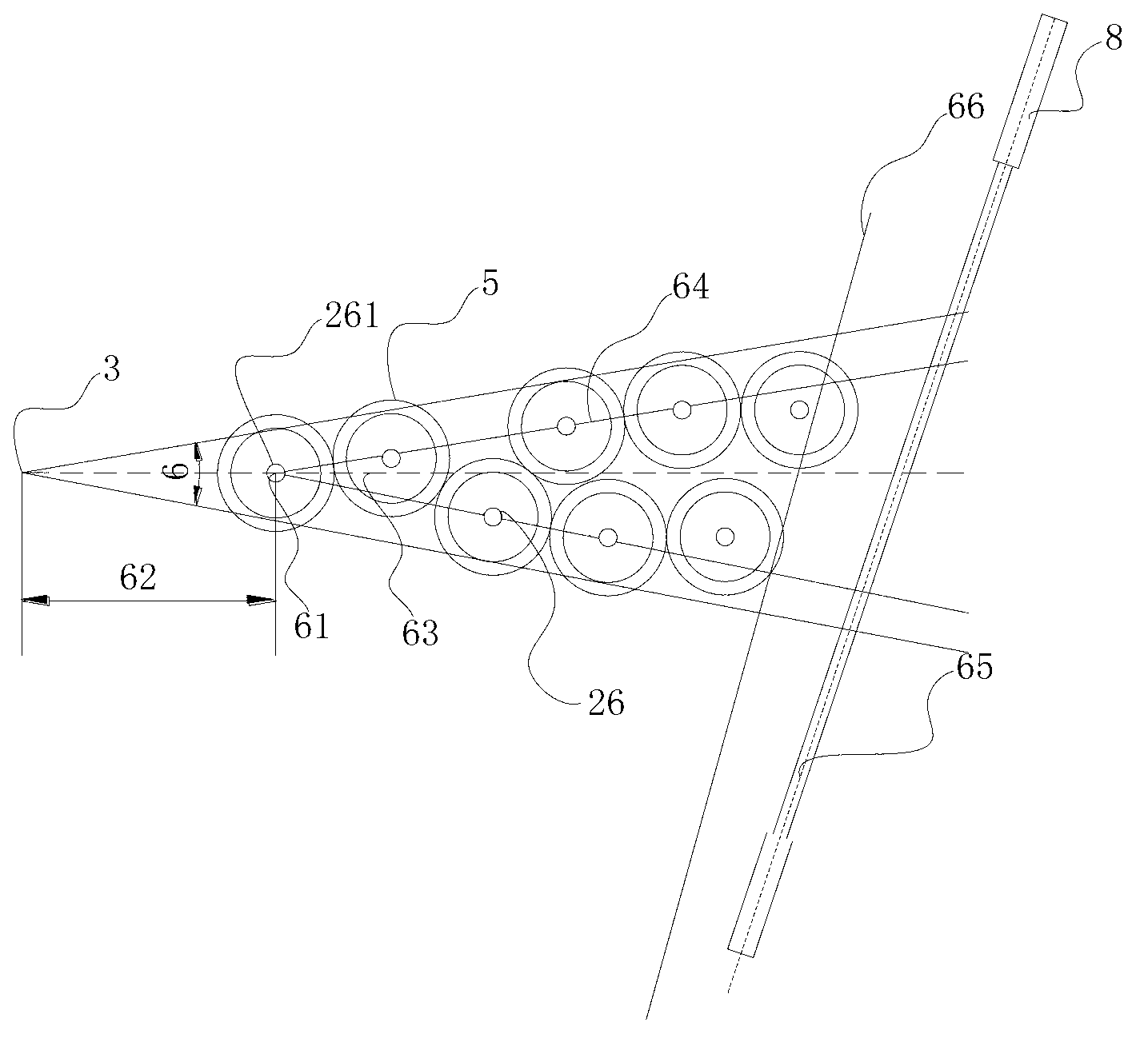

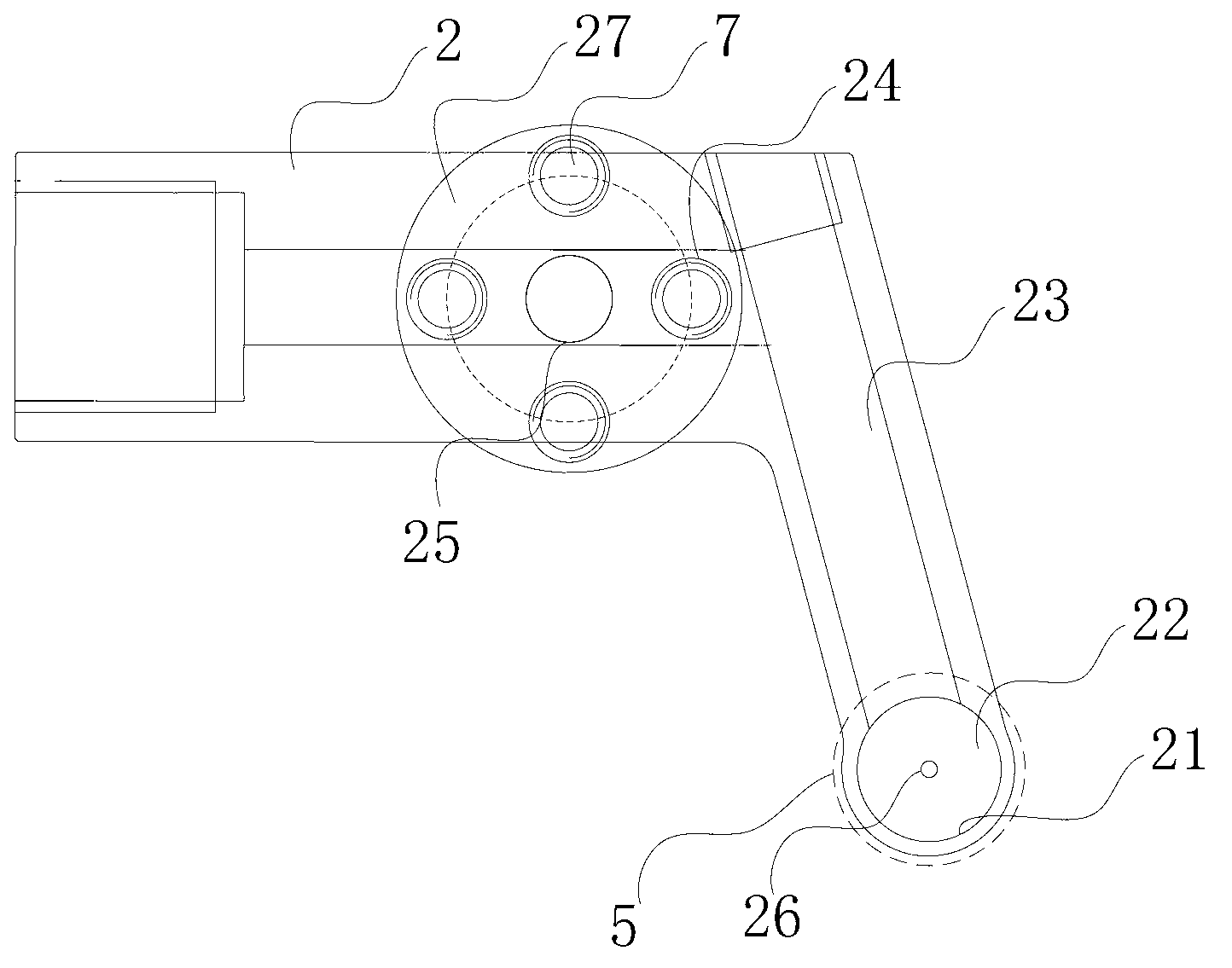

[0044] Such as Figure 1~Figure 10 Shown is the multi-jet combination device of the weft insertion mechanism of the water jet loom, including several needle seats 2 installed on the bracket 1, each needle seat 2 is provided with a mounting hole 21, and each mounting hole 21 is equipped with There is a needle body 22, and each needle body is equipped with a needle 26, and there is a first position point 61 on the bisector of the minimum permissible opening 6 formed by the upper and lower warp threads when the water jet loom starts weft insertion from the weaving fell 3, The distance between the first position point 61 and the fabric fell is the minimum allowable distance 62; the center position of the minimum design allowable space 5 of each spray needle is set at two parallel openings parallel to the minimum allowable opening 6 drawn from the first position point 61. The triangular area 4 is formed by the line 64 and the maximum allowable position 66 away from the fabric fell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com