Detection algorithm of cement concrete pavement slab staggering quantity

A technology of cement concrete and detection algorithm, applied in roads, roads, calculations, etc., can solve the problems of high cost, low efficiency, and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

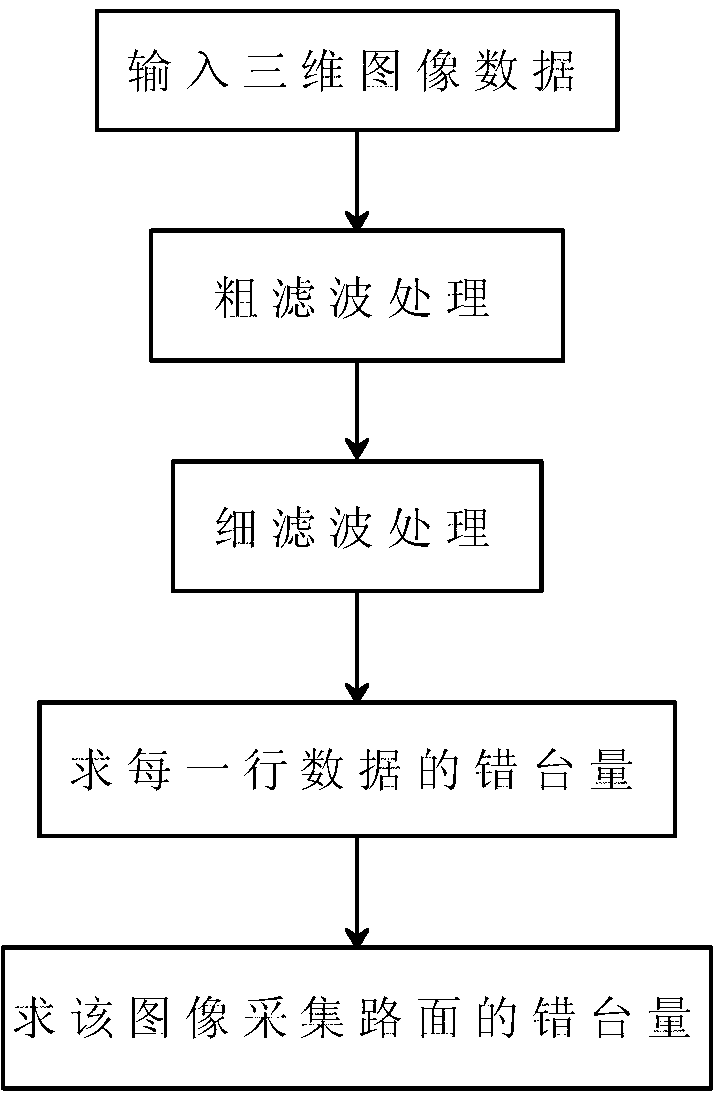

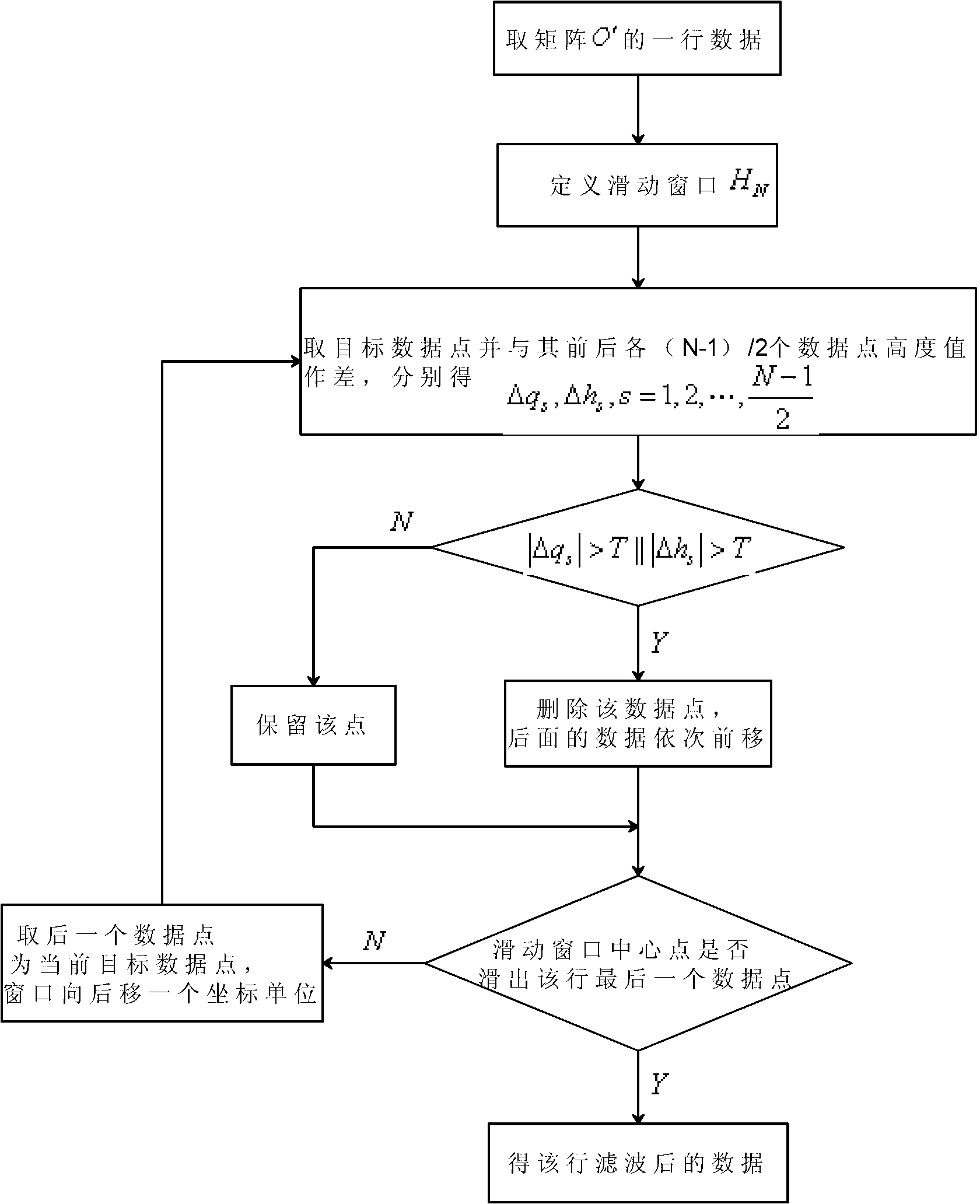

[0036] see Figure 1-Figure 4 , the detection algorithm of a kind of cement concrete pavement misalignment amount of the present invention, specifically comprises the following steps:

[0037] Step 1: Input the image three-dimensional data matrix, and filter the data;

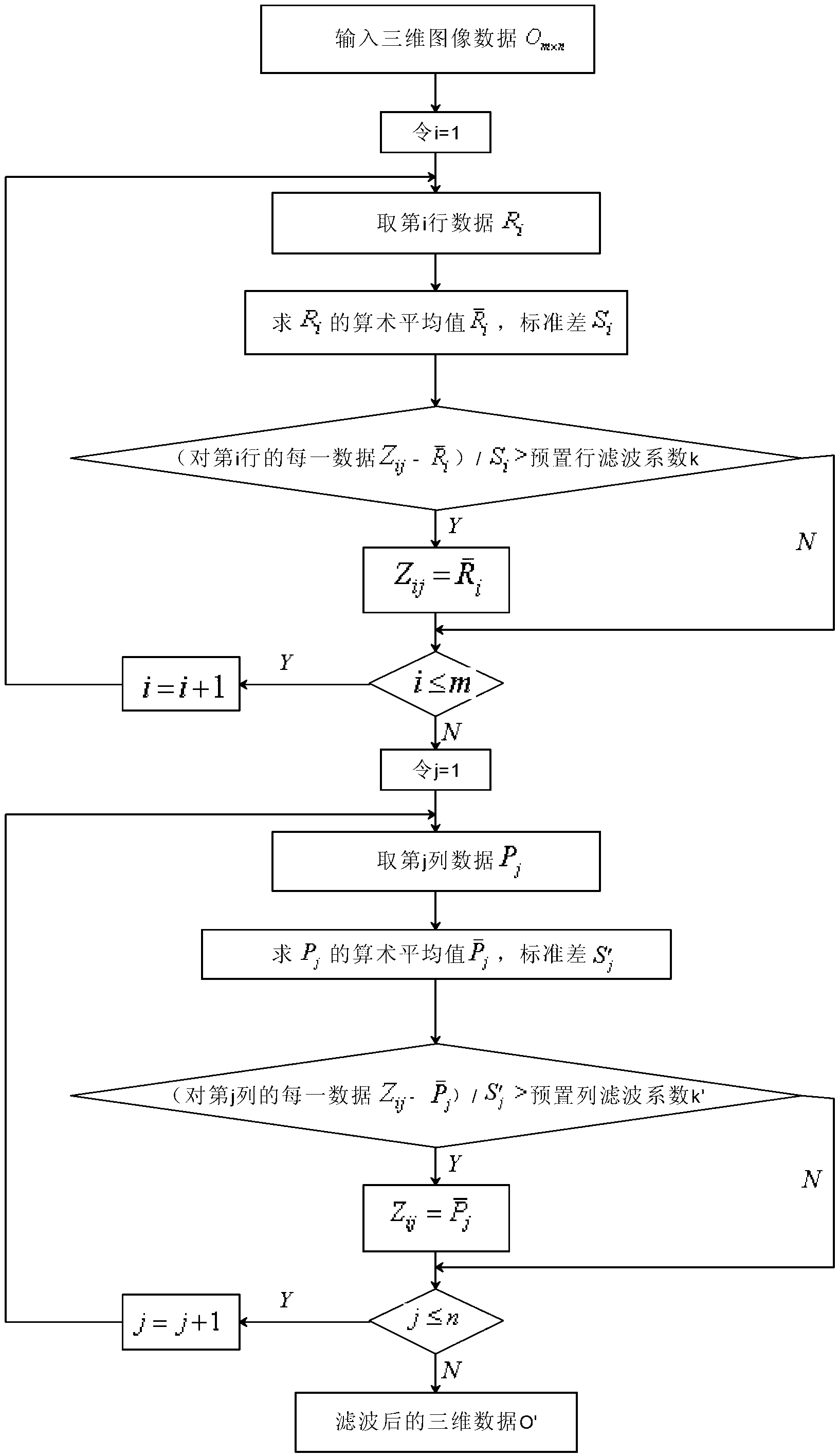

[0038] The three-dimensional image data matrix collected by the image acquisition device is input into the computer, and the computer reads the three-dimensional image data matrix O m×n , m=1000 and n=1536 are taken in this embodiment.

[0039] (1) Perform rough filtering on the data, including two processes of eliminating noise points in the image row by row and eliminating noise points in the image column by column. The steps are as follows:

[0040] 1) Take the data of each row of the three-dimensional image data matrix O row by row, such as the i-th row R i =(z i1 ,z i2 ,…z i,1536 ), i=(1,2,...1000), find R i arithmetic mean of and standard deviation S i ;

[0041] 2) Take each data z in the row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com