Powerful confined concrete core wall with obvious columns and hidden beams

A technology for confining concrete and concrete, applied in the direction of building and building structure, can solve the problems affecting the seismic safety of the core tube structure, the decline of the horizontal bearing capacity, and the poor deformation performance, so as to improve the seismic safety, the horizontal bearing capacity and the The effect of improved deformability and improved seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

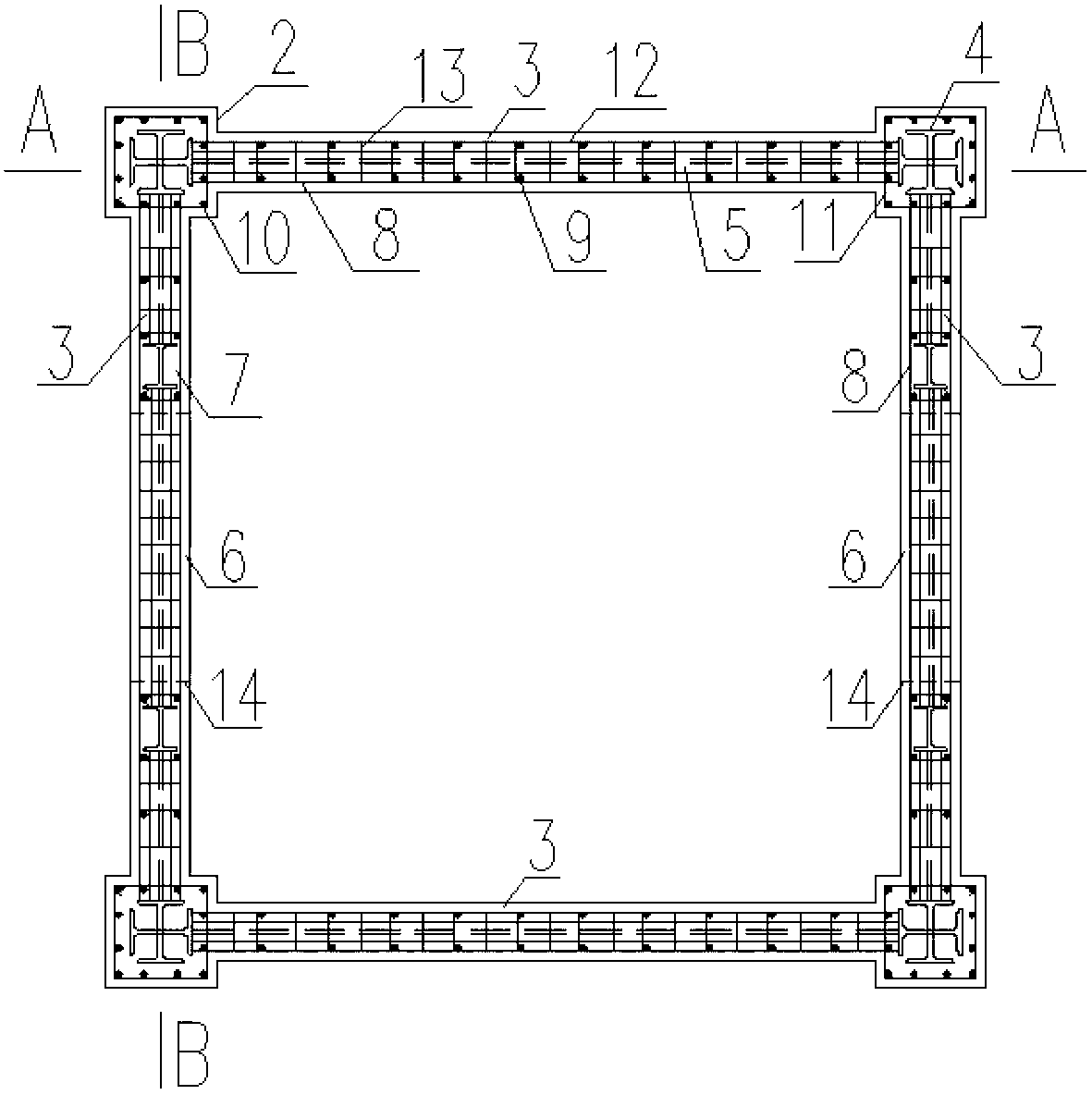

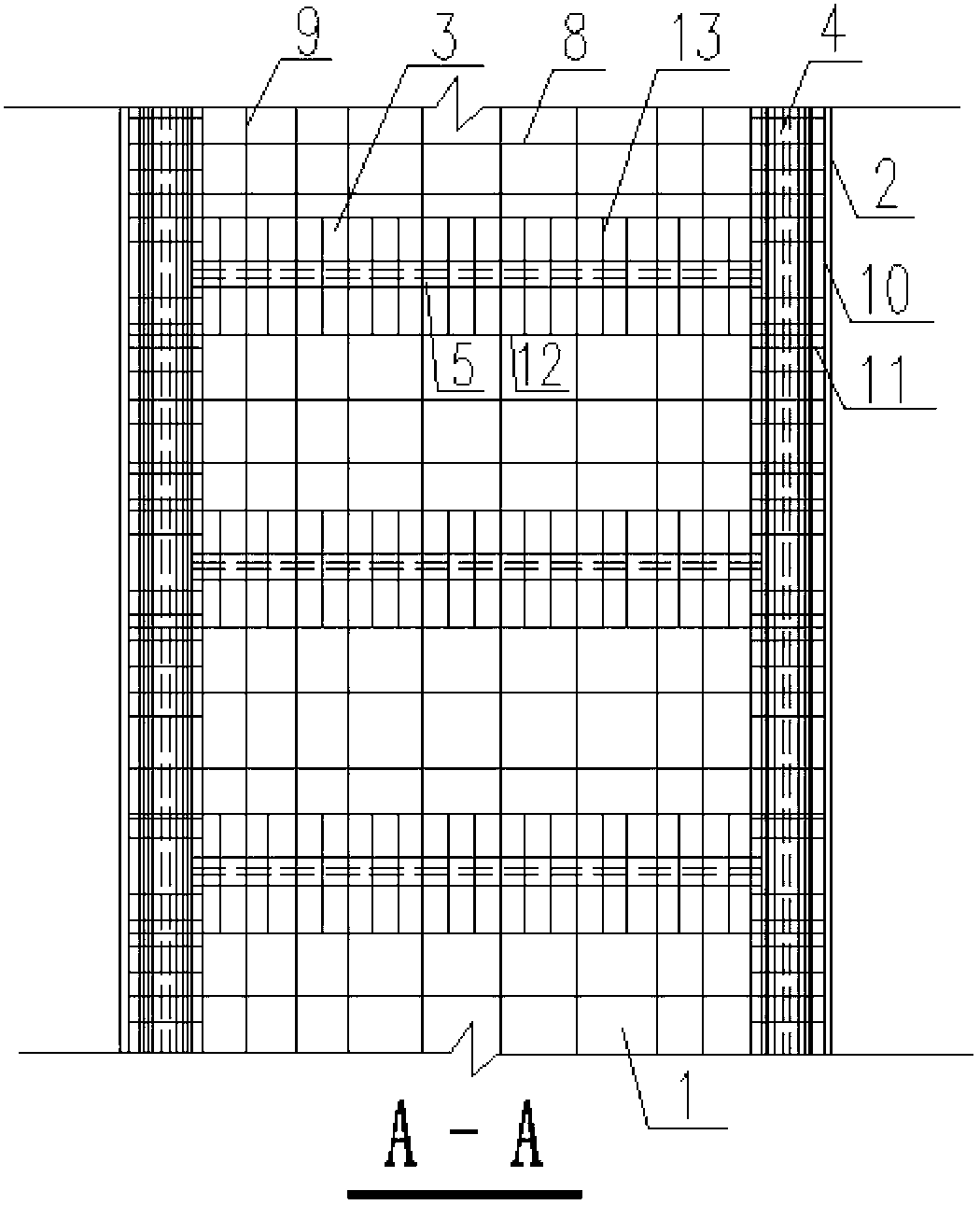

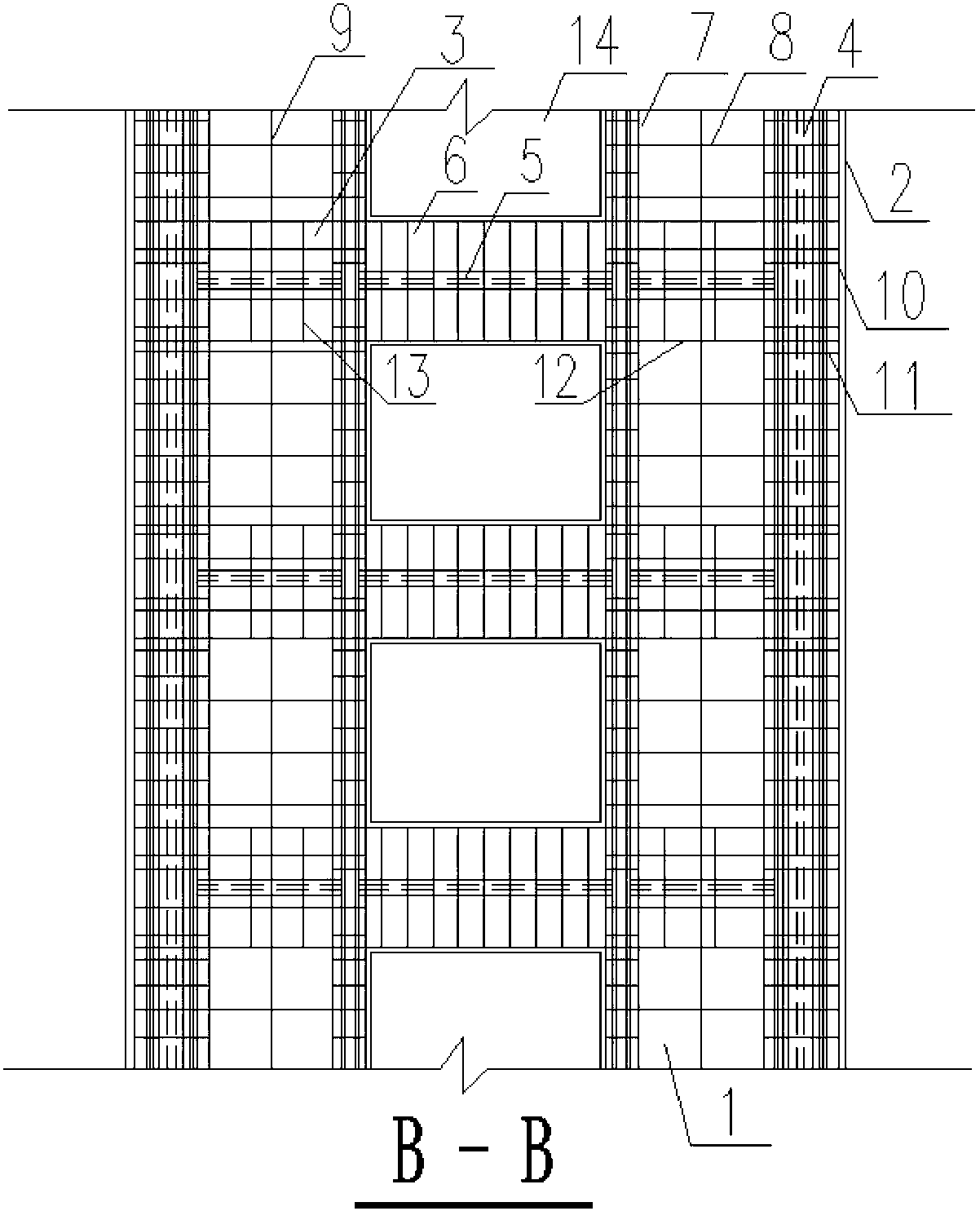

[0019] Figure 1 ~ Figure 3 Shown is a frame-column cross-section of a rectangular exposed-column-beam-constrained concrete core. The core tube is composed of concrete walls 1, concrete frame columns 2 and hidden beams 3 in the concrete walls. In the concrete wall 1, the horizontally distributed steel bars 8 and the vertically distributed steel bars 9 of the wall are configured according to conventional methods; the concrete frame columns 2 are arranged at the intersection of the concrete wall 1 in two directions at each corner of the core tube, and the concrete frame columns The horizontal cross-sectional dimensions of 2 are respectively greater than the thickness of the adjacent concrete walls 1 in the thickness direction, forming a rectangular cross-section exposed column protruding from the wall, and the concrete frame column 2 is equipped with concrete frame column longitudinal reinforcement 10 And the concrete frame column stirrup 11, the wall horizontally distributed r...

Embodiment 2

[0021] Figure 4 ~ Figure 5 Shown is a concrete core tube with exposed columns and hidden beams with an L-shaped cross-section of frame columns. The core tube is composed of concrete walls 1, concrete frame columns 2 and hidden beams 3 in the concrete walls. In the concrete wall 1, the horizontally distributed steel bars 8 and the vertically distributed steel bars 9 of the wall are configured according to conventional methods; the concrete frame columns 2 are arranged at the intersection of the concrete wall 1 in two directions at each corner of the core tube, and the concrete frame columns The horizontal cross-sectional dimensions of 2 are respectively greater than the thickness of the adjacent concrete walls 1 along the thickness direction, forming an L-shaped cross-sectional exposed column that protrudes from the wall surface and has an inner concave angle. The concrete frame column 2 is equipped with concrete Frame column longitudinal reinforcement 10 and concrete frame c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com