Stamping part connecting fastening structure

A technology for connecting fastening and sheet metal parts. It is applied in the direction of connecting components, bolts, mechanical equipment, etc. It can solve the problems of inconvenient maintenance, nuts are easy to fall off, and increase the assembly process, etc., to achieve effective limit function and ensure tight connection. , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the present invention will be further described in detail through embodiments and in conjunction with the drawings:

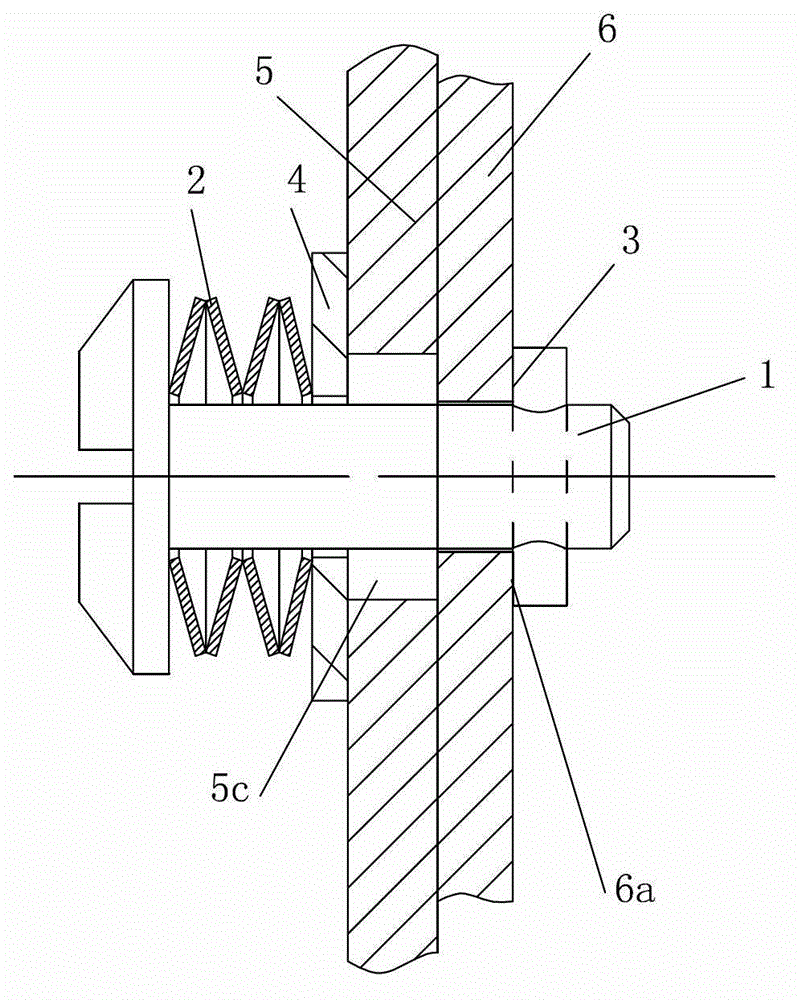

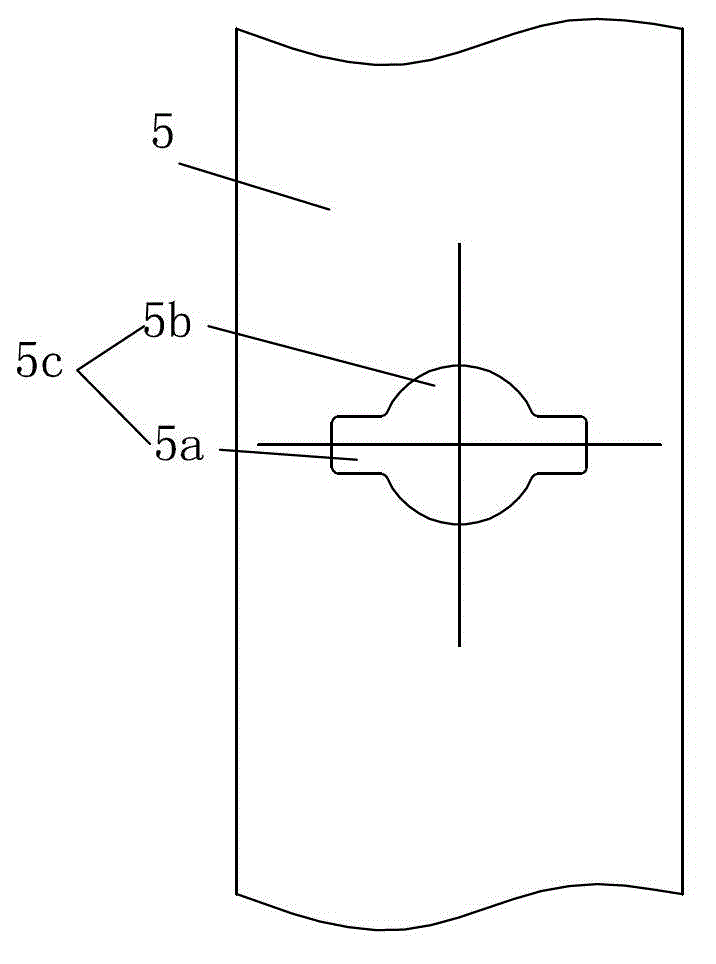

[0029] Such as figure 1 The shown connection and fastening structure of sheet metal parts is composed of a first sheet metal part 5, a second sheet metal part 6 and a fastening connection component. The fastening connection component consists of a connecting rod 1, a return spring 2, and a limit pin 3 and 4 flat pads.

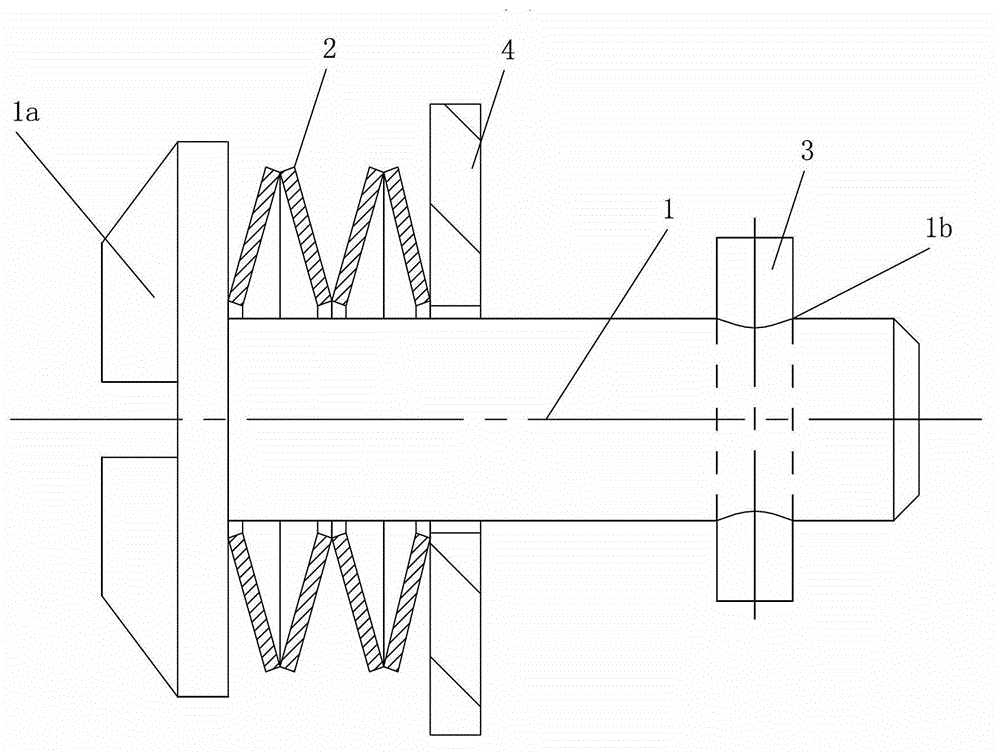

[0030] Such as figure 2 As shown, the connecting rod 1 has an end 1a, the return spring 2 and the flat washer 4 are sequentially sleeved on the connecting rod 1, and the lower end of the connecting rod 1 is provided with a pin through hole 1b, and the limit pin 3 is inserted through the pin. The hole 1b is fixedly connected with the connecting rod 1. The return spring 2 and the flat pad 4 are located between the end 1a of the connecting rod 1 and the pin through hole 1b. The axis of the pin through hole 1b intersects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com