Bearing element for slide bearing utilized for supporting drive shaft of hydraulic machine i.e. axial piston pump, has supporting rod elastically deformable such that bending of drive shaft and/or misalignment in rod is compensated

A technology of bearing components and sliding bearings, which is applied in the field of hydraulic presses and can solve problems such as deformation and sliding bearing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

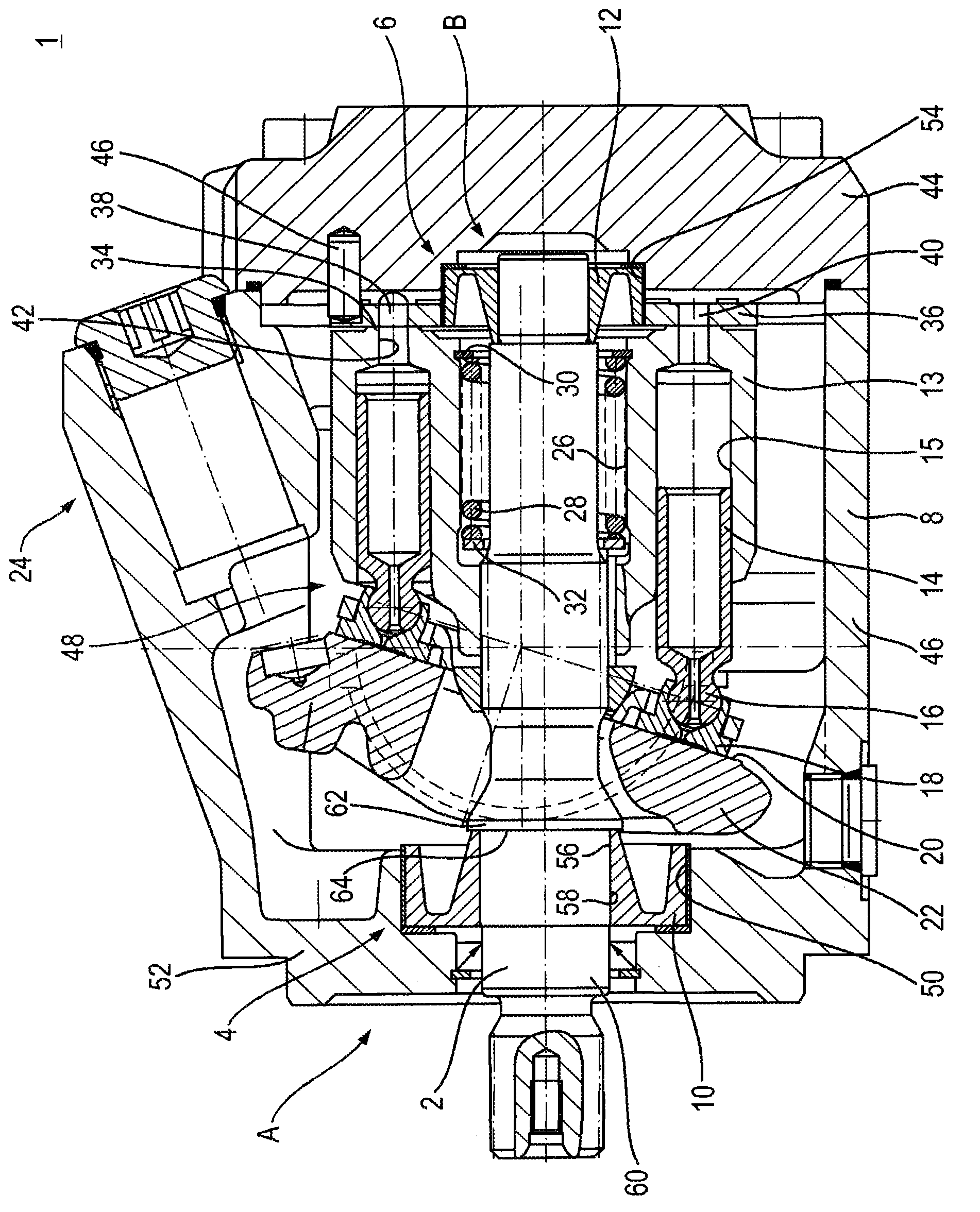

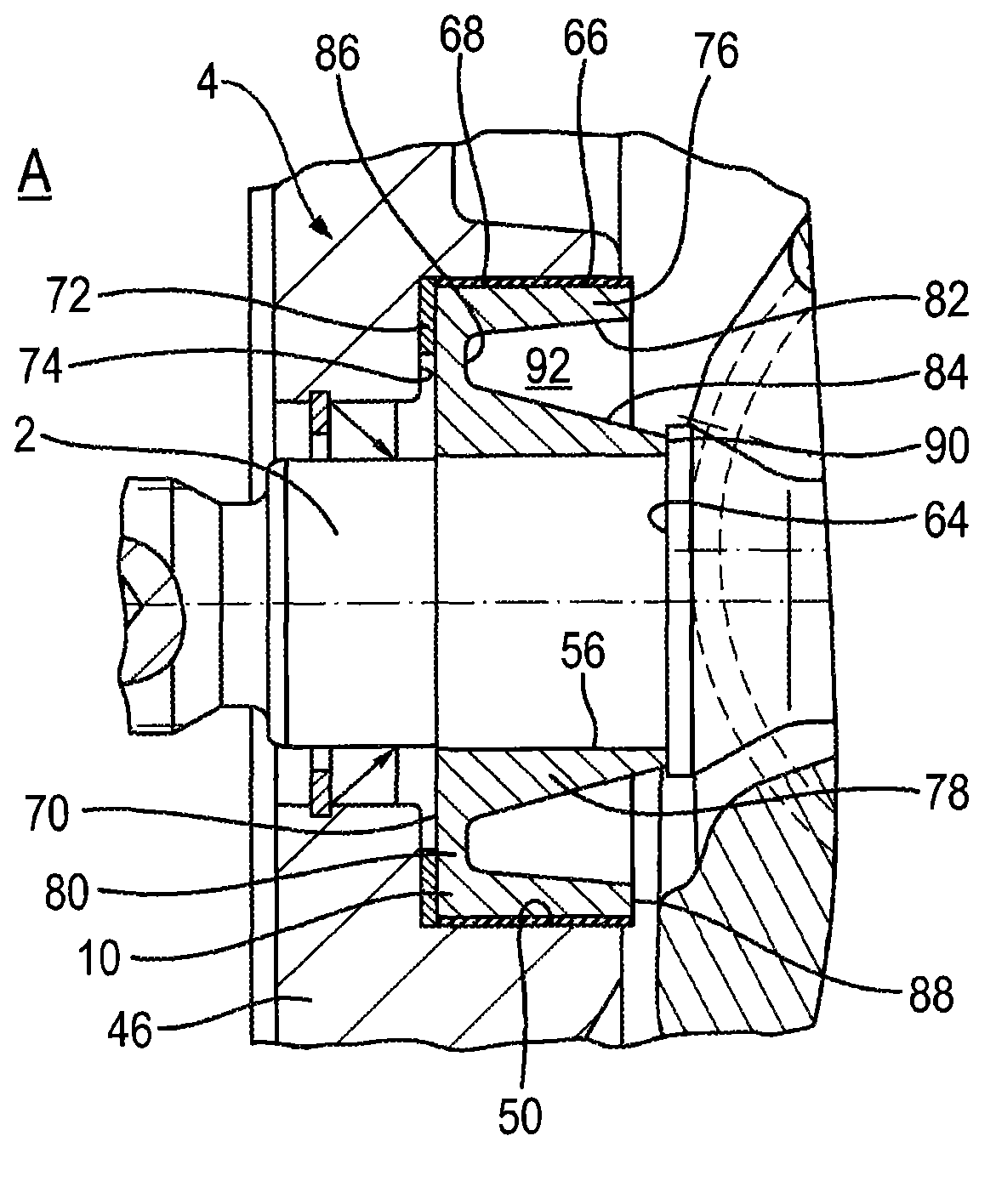

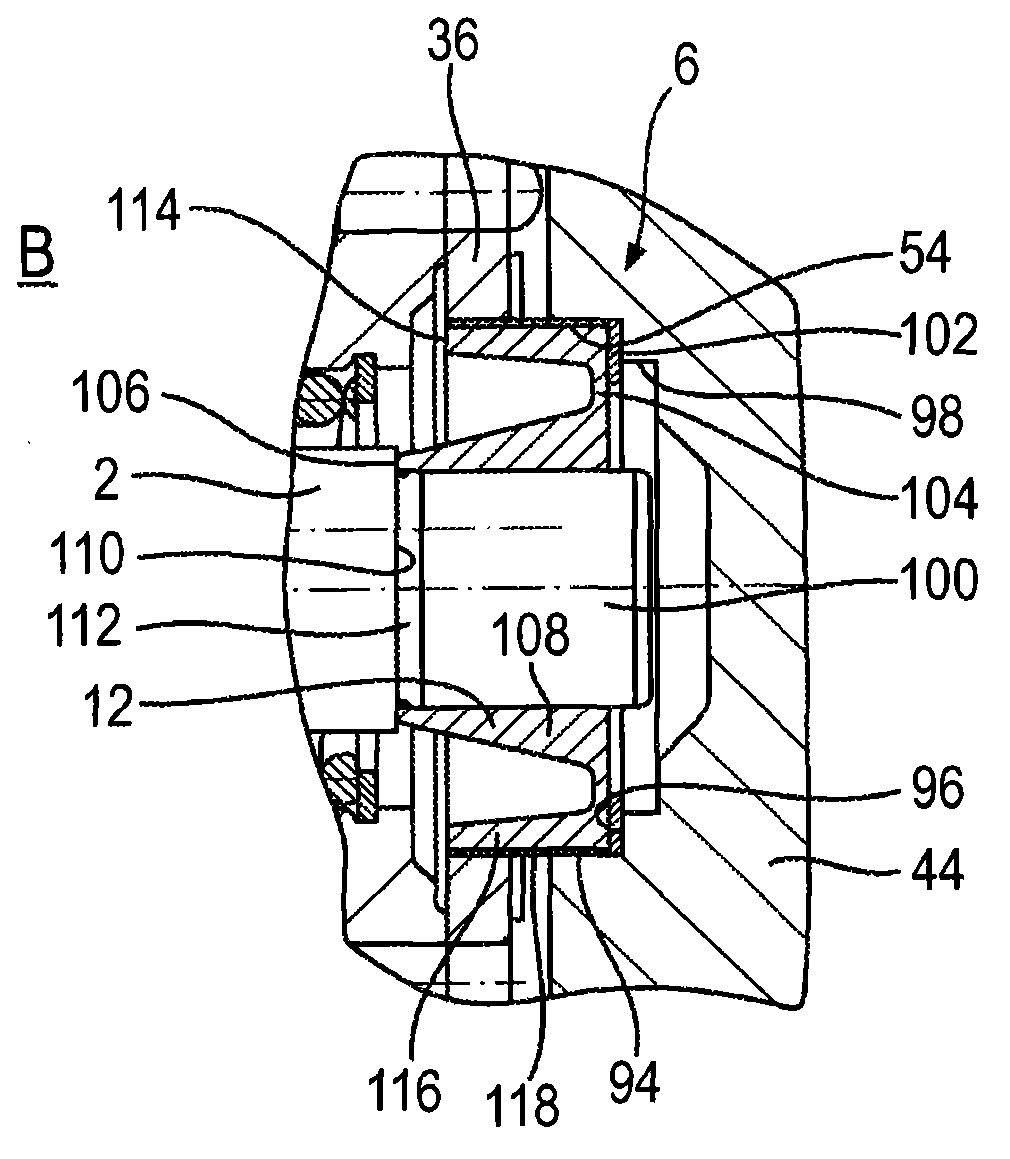

[0032] according to figure 1 The axial piston machine shown is an axial piston machine, in particular an axial piston pump of swash plate design, which is designated by the applicant as type A10 VO 45 and which is also operated with HFC fluids. The axial piston machine has a drive shaft 2 , in particular a drive shaft designated A10 by the applicant, which is slidingly mounted in a machine housing 8 of a hydraulic machine 1 via two plain bearings 4 and 6 according to the invention. The slide bearings 4 and 6 each have a bearing part 10 or 12 according to the invention, by means of which shaft deflections of the drive shaft and concentricity errors or misalignment errors of the slide bearings 4 and 6 can be compensated. On the slide-mounted drive shaft 2 a cylindrical roller 13 is arranged in the axial direction between the slide bearings 4 and 6 . The cylindrical drum is penetrated by the drive shaft 2 , wherein the cylindrical drum 13 and the drive shaft 2 are connected so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com