Micro-irrigation capillary pipe inlet flow adjuster

A technology of inlet flow and regulator, applied in the direction of valve details, function valve types, applications, etc., can solve the problems of narrow working pressure range, low assembly efficiency, high processing precision requirements, etc., and achieve the effect of increasing the working pressure range and pressure compensation Good, precise flow adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

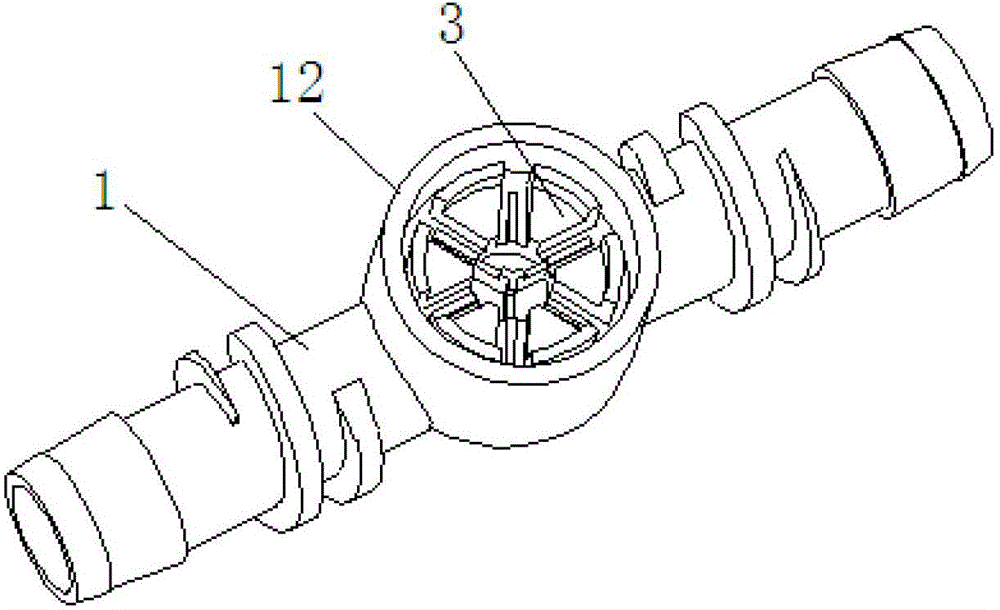

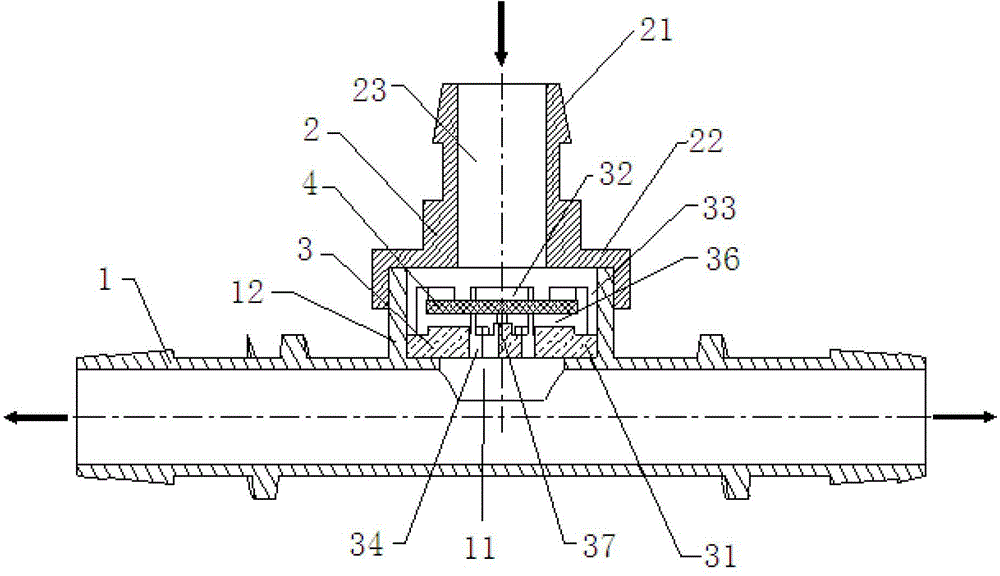

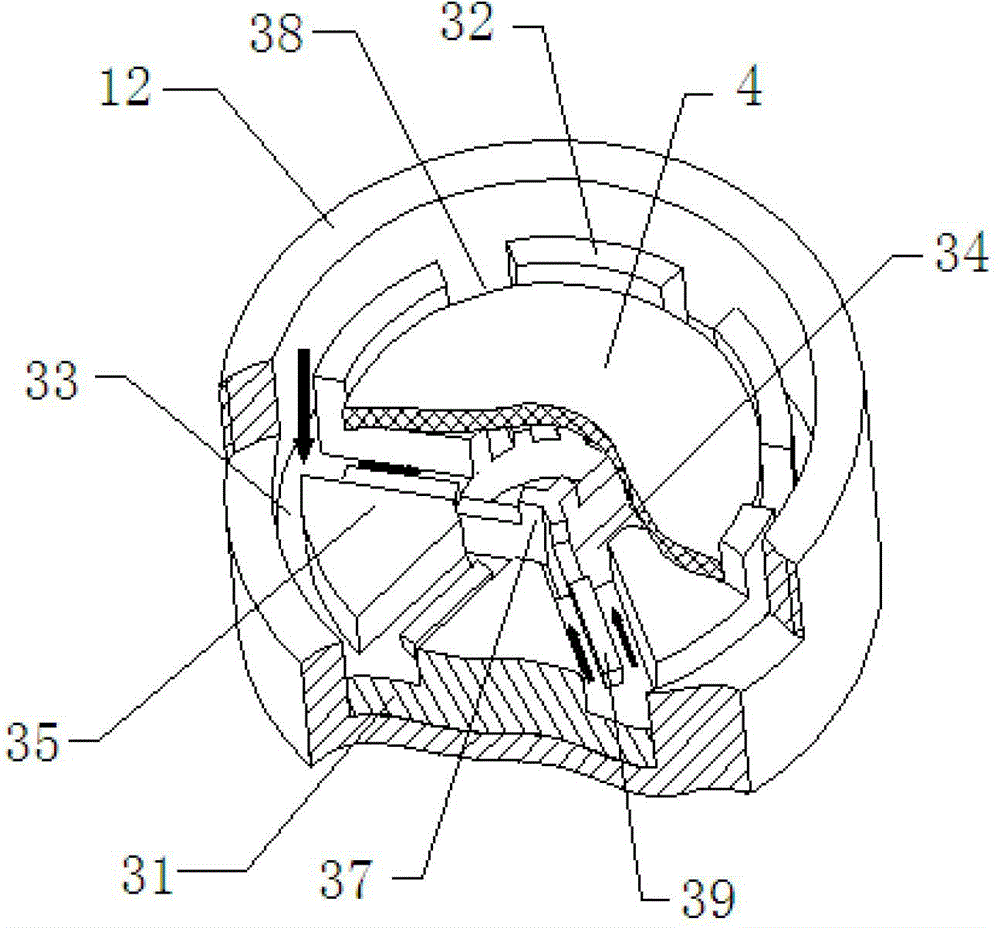

[0028] Such as figure 1 , figure 2 As shown, Embodiment 1 includes a water outlet base 1 , a water inlet cover 2 , a core seat 3 and a disc-shaped elastic diaphragm 4 .

[0029] Such as figure 1 , figure 2 As shown, the water outlet base 1 is a cylindrical pipe, the side wall of the water outlet base 1 is provided with a circular hole 11, and the outer wall of the water outlet base 1 in the circumferential direction of the circular hole 11 is integrally provided with a cylindrical interface pipe 12, and the cylindrical interface pipe The inner diameter of 12 is greater than the diameter of circular hole 11, and the top of cylindrical interface pipe 12 is connected to water inlet cover 2 by thread, or the top of cylindrical interface pipe 12 is plugged in water inlet cover 2, or the top of cylindrical interface pipe 12 The top is ultrasonically welded in the water inlet cover 2. The circular hole 11 and the water inlet cover 2 are used as the water inlet, and the two en...

Embodiment 2

[0034] Such as Figure 6 As shown, the second embodiment includes a water outlet base 1 , a water inlet cover 2 , a core seat 3 and a disc-shaped elastic diaphragm 4 .

[0035] Such as Figure 6 As shown, the water outlet base 1 is a cylindrical pipe, one end of the water outlet base 1 is used as the water inlet, and the other end is used as the water outlet. The water inlet end is equal to the circular hole 11 provided on the side wall of the water outlet base 1 in the first embodiment, and the outer wall of the water outlet base 1 in the circumferential direction of the water inlet end is integrally provided with a cylindrical interface pipe 12, and the inner diameter of the cylindrical interface pipe 12 is Greater than the diameter of the water inlet end, the top of the cylindrical interface pipe 12 is threaded to the water inlet cover 2, or the top of the cylindrical interface pipe 12 is inserted into the water inlet cover 2, or the top of the cylindrical interface pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com