Pressure-auto-balance hydrodynamic noise silencer

A self-balancing, hydrodynamic technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., it can solve the problems of single silencing frequency, limited application, increasing volume, etc., to achieve noise suppression and silencing frequency. Highly adjustable, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

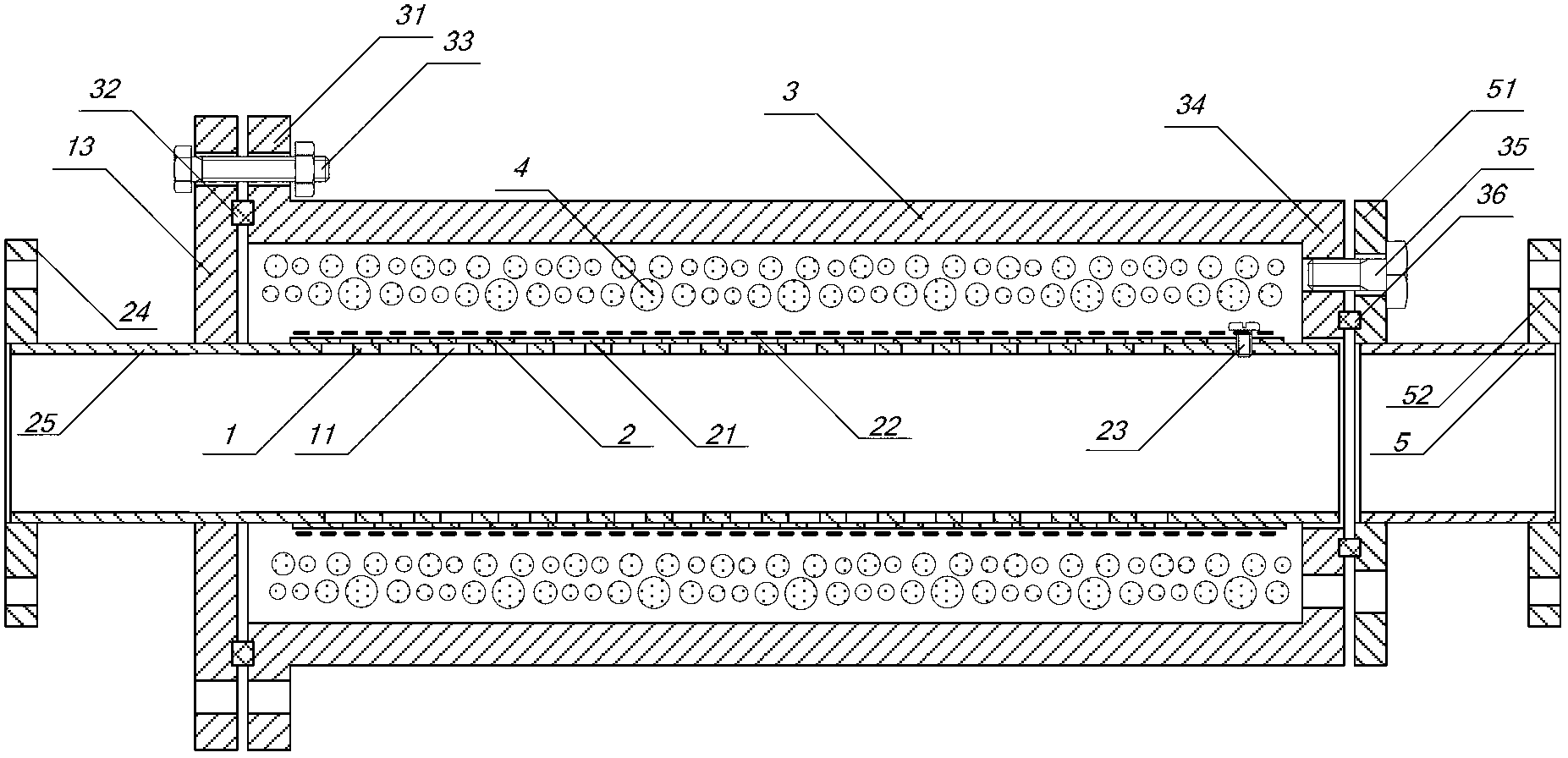

[0026] combine Figure 1-7 , the present invention has a cylindrical inner layer perforated pipe 1, a cylindrical outer layer perforated pipe 2 placed coaxially, the inner layer perforated pipe 1 is closed and connected with its end face flange 13, and the outer layer perforated pipe 2 is covered with Wire mesh 22; outer layer perforated pipe 2 and its end face flange 13, cylindrical housing 3 form a chamber, the chamber is filled with a plurality of inflatable balls or other shapes, closed, compressible elastic elements 4, Small balls or other shapes, closed, compressible elastic elements 4 have different sizes; the relative position between the inner perforated tube 1 and the outer perforated tube 2 can be changed by adjusting the screw 23; the right end surface of the cylindrical housing 3 34 and the left end face 51 of the outlet pipe section are connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com