Automobile gearbox taper rolling child bearing height measuring device

The technology of a tapered roller bearing and a height measuring device is applied in the field of bearing processing, which can solve the problems of low work efficiency, high labor intensity, and large error in the height measurement of the tapered roller bearing of an automobile gearbox, so as to achieve rapid and accurate measurement and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

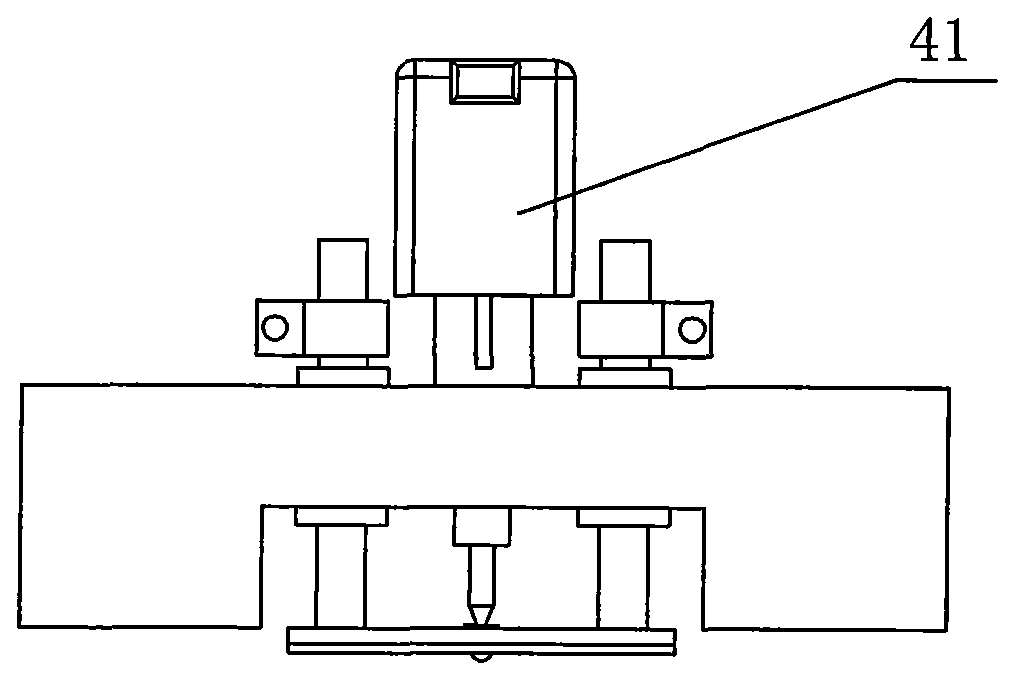

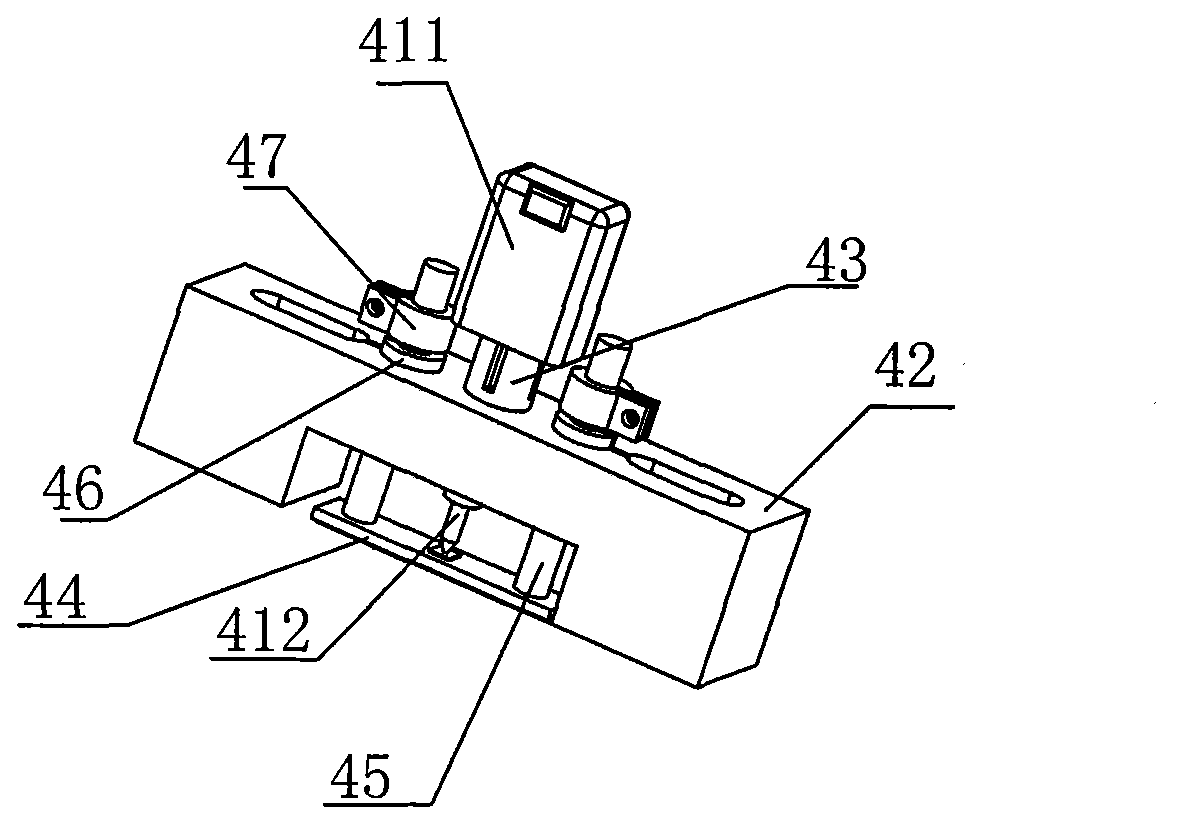

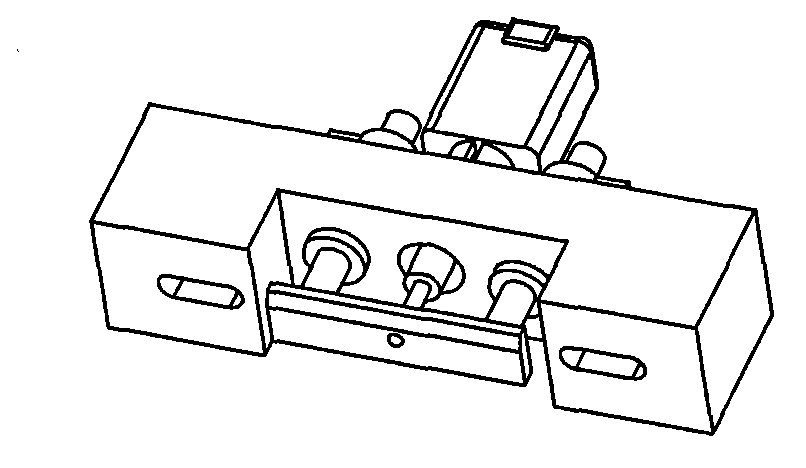

[0027] Such as Figure 1 to Figure 6 As shown, a tapered roller bearing height measuring device for automobile gearbox includes a bearing 1, a bracket 2, a bearing material channel 3, a height measuring system 4, a data display device 5 and a discharge system 6, and the bearing material channel 3 includes Bottom plate 31 and left retaining bar 32, right retaining bar 33, described base plate 31 is fixedly arranged on the support 2, and described left retaining bar 32, right retaining bar 33 are fixedly arranged in parallel on both sides of bearing material path bottom plate 31, and described height Measuring system 4 comprises measuring pen 41, and described measuring pen is the GT2-H12 type measuring pen that Keyence produces, repeatability 1um, and described measuring pen comprises upper pen body 411, middle connecting part (not shown in the figure) and lower part The nib 412, the upper pen body 411 and the middle connection part are integrated, the lower nib 412 is movably ...

Embodiment 2

[0041] A device for measuring the height of a tapered roller bearing of an automobile gearbox. The model of the bearing 1 is 11949. The height of the model of the bearing 1 is 16.5mm. 1 to match the height of 16.5mm; the rest is the same as embodiment 1.

Embodiment 3

[0043] A device for measuring the height of a tapered roller bearing of an automobile gearbox. The model of the bearing 1 is 69349, and the height of the model of the bearing 1 is 17mm. The installation height of the measuring pen 41 is adjusted by adjusting the ferrule 47 so that it is in line with the measured bearing 1 The height 17mm matches; The rest is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com