A sealing performance tester with temperature compensation function and sealing performance testing method

A technology of sealing performance and temperature compensation, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the rate of increase and deceleration of fluid, can solve the problems of low efficiency, high cost, and inaccurate testing, and reduce production cost, increased openness, and enhanced reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

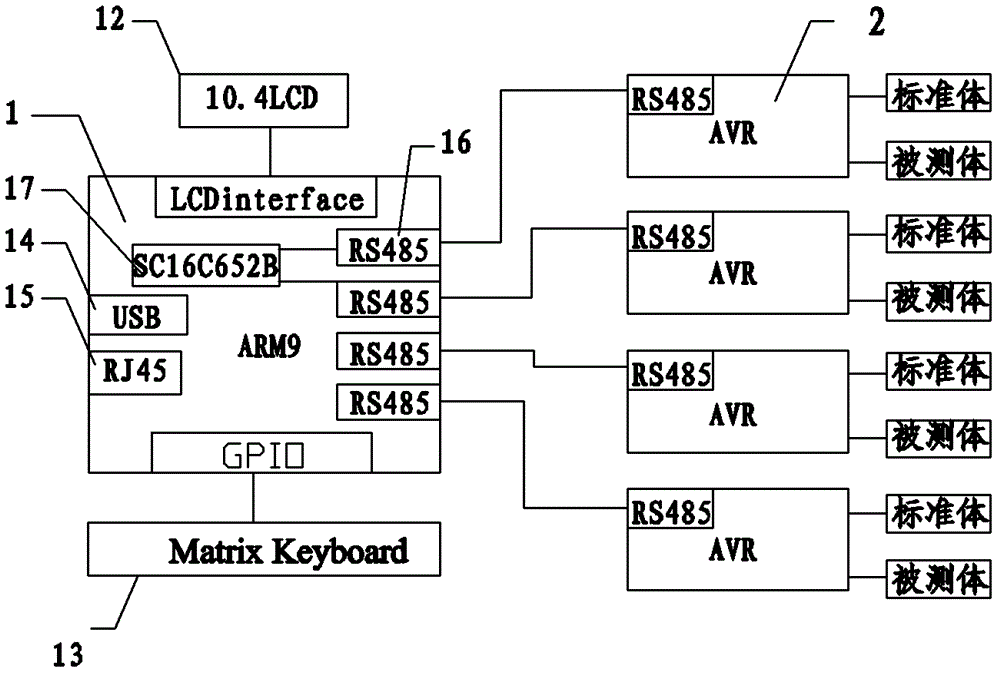

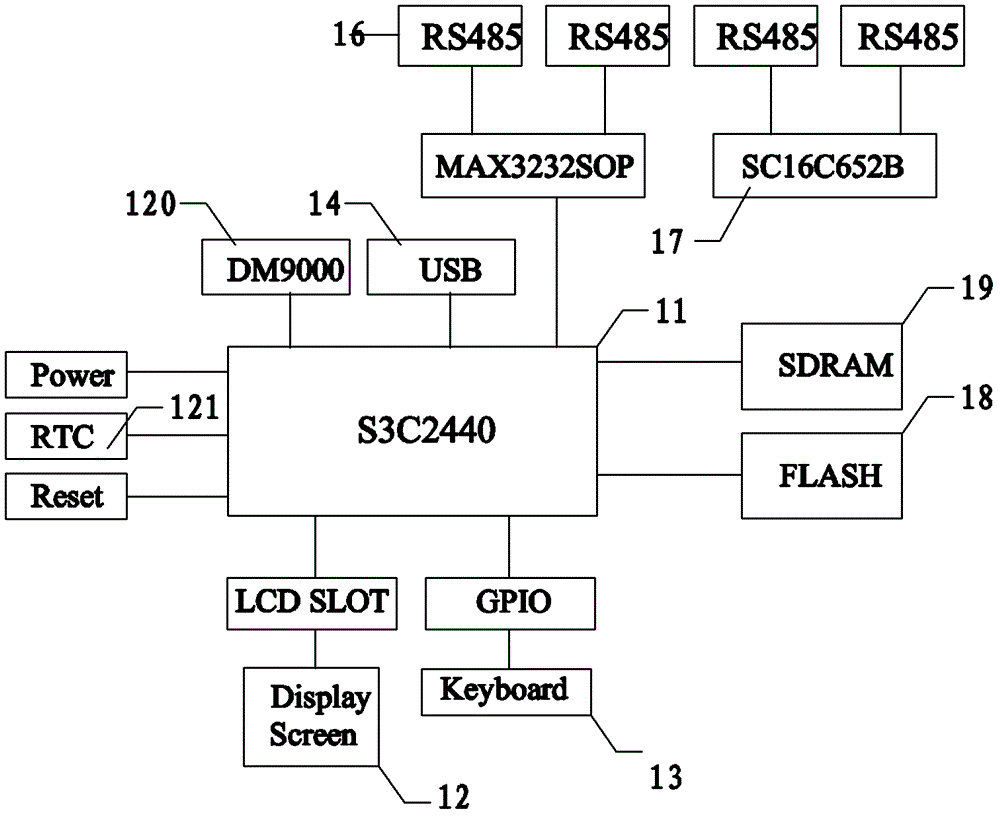

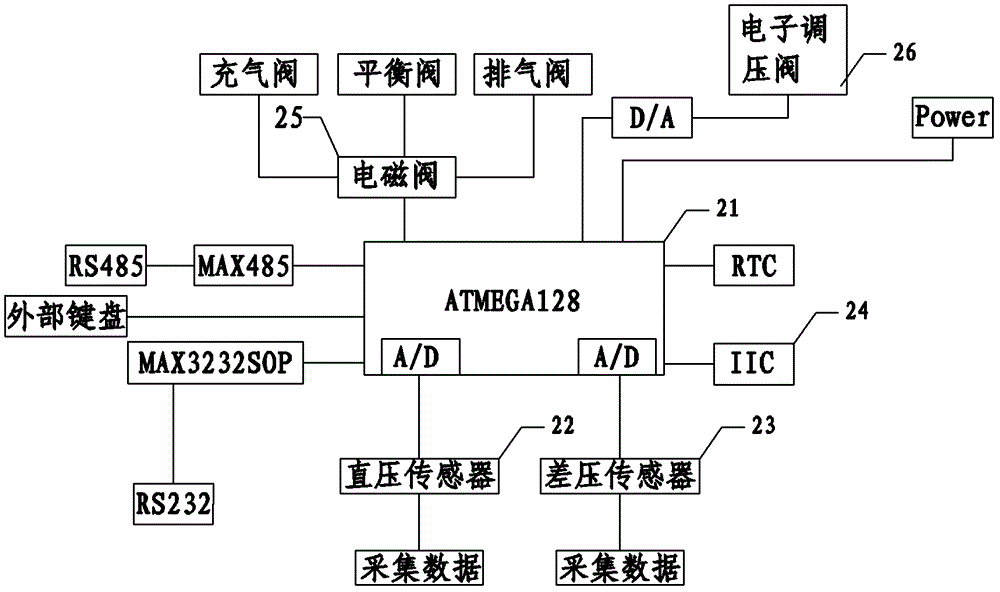

[0036] like Figure 1 ~ Figure 4 As shown, a sealing performance tester includes a sealing tank, a first collecting end, a second collecting end and a processing unit, figure 1 The structural block diagram of the processing unit 1 is as follows: figure 2 As shown, the ARM9 core board consists of ARM9 microprocessor, power circuit, 64M Flash 18, 64M SDRAM19, GPIO outlet, LCD chip based on line and field scanning, LCD chip externally connected to the LCD display slot, USB port, real-time Clock RTC 121, DM9000 network card chip 120, DM9000 network card chip 120 is externally connected to the Ethernet RJ45 socket, the serial port chip MAX3232SOP is externally connected to two RS485 ports, and the serial port expansion chip SC16C652B is externally extended to form two RS485 ports. Connect to the keyboard.

[0037] In this embodiment, the processing unit 1 includes an ARM9S3C2440 microprocessor 11 for processing data and controlling each hardware module, and those skilled in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com