Automatic Image Capture Magnetic Particle Flaw Detector for Train Axle

A magnetic particle flaw detection and automatic image technology, applied in the direction of material magnetic variables, can solve the problems of operator health damage, easy missing inspection, time-consuming and labor-intensive problems, and achieve the effect of avoiding long-term work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

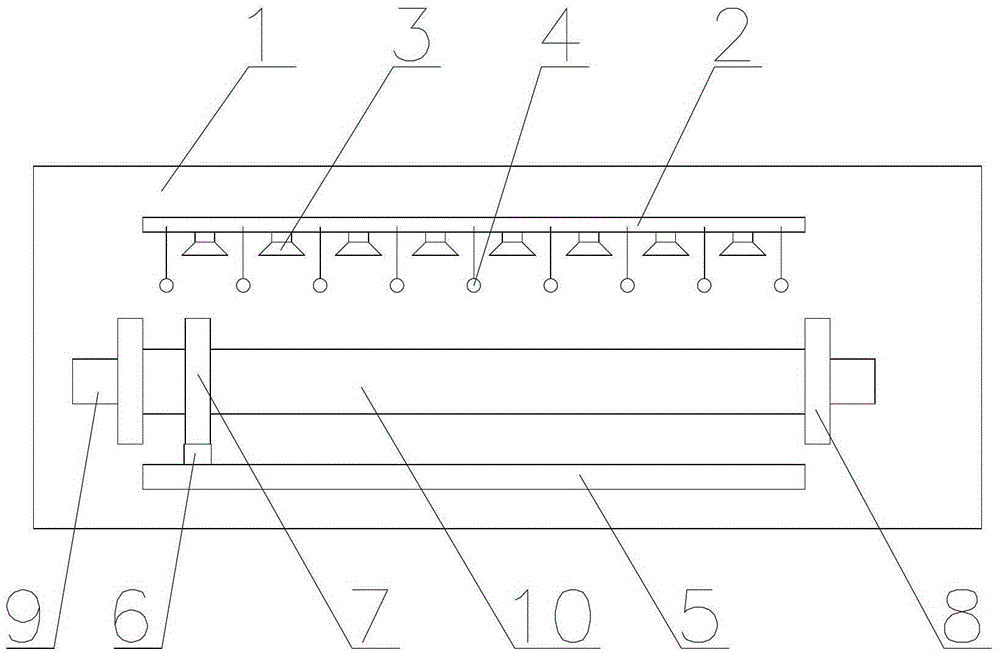

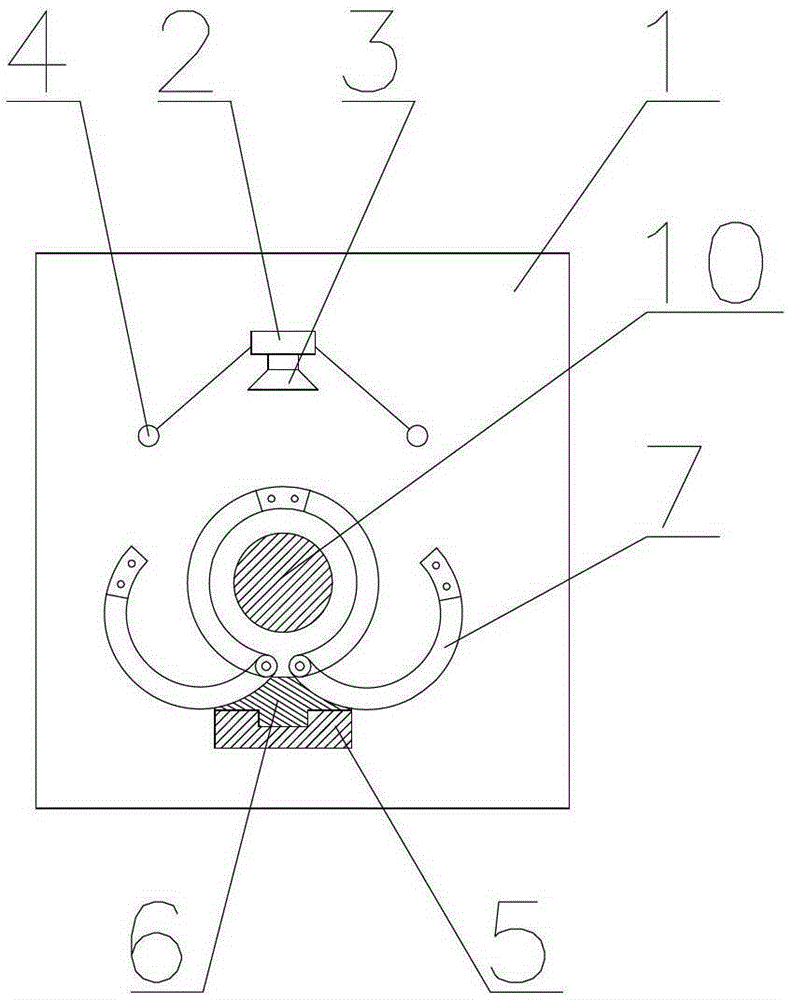

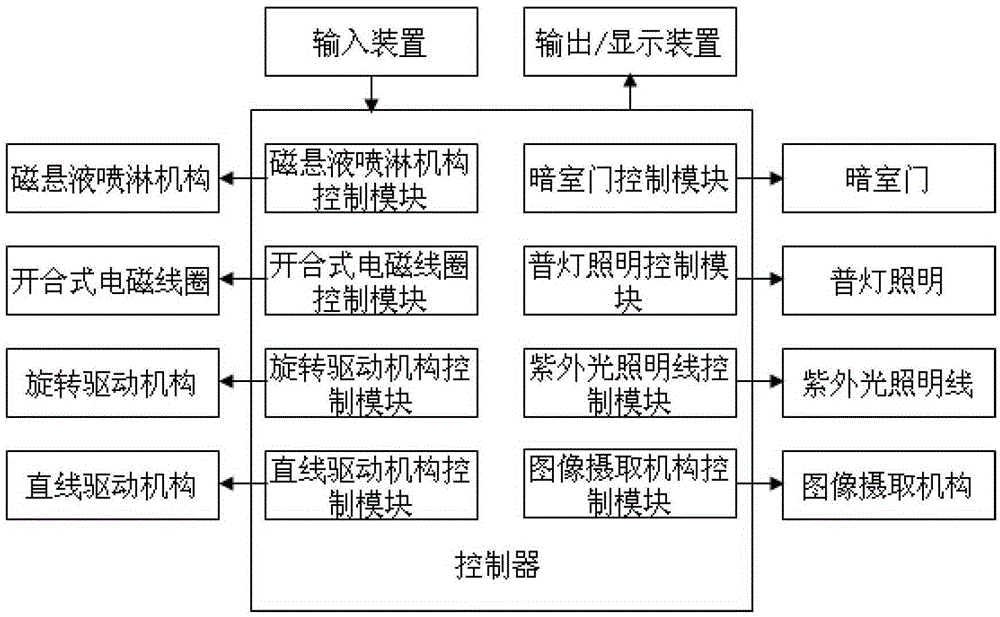

[0024] Such as figure 1 , figure 2 Shown is a magnetic particle flaw detection machine with automatic image capture for train axles, which is characterized in that it includes a darkroom 1 in which a suspension 2, a general lamp lighting mechanism, a magnetic particle flaw detection body and a controller are arranged.

[0025] The magnetic particle inspection body includes a magnetic suspension spray mechanism, a split electromagnetic coil 7, a linear guide rail 5, a workpiece fixture 8, a rotary drive mechanism 9, a demagnetization mechanism, and a linear drive mechanism; the split electromagnetic coil 7 includes a left claw and the right claw, the head of the left claw and the right claw is provided with a suitable locking mechanism, and the root is installed on the slider 6 through a collector ring; the slider 6 is installed on the linear guide rail 5, and the Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com