Cable terminal steel pipe pole

A cable terminal and steel pipe rod technology, which is applied to the installation of cables, the spatial arrangement/configuration of cables, electrical components, etc., can solve the problems of difficult to handle the electrical clearance, easy heating of the cable iron, and difficulty in fixing the cable. The effect of saving cable material, saving copper material and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

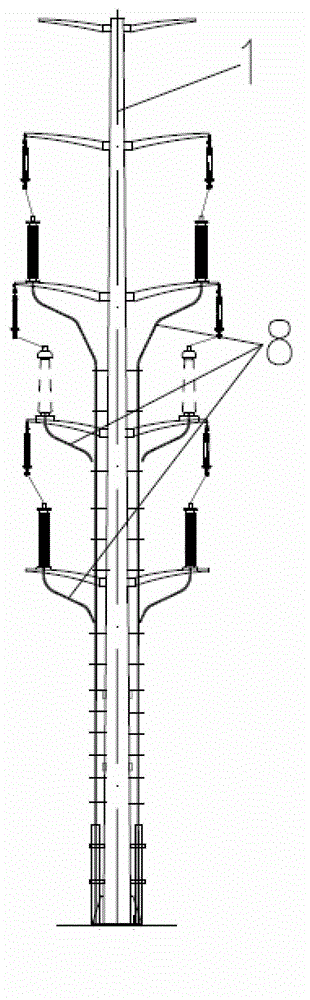

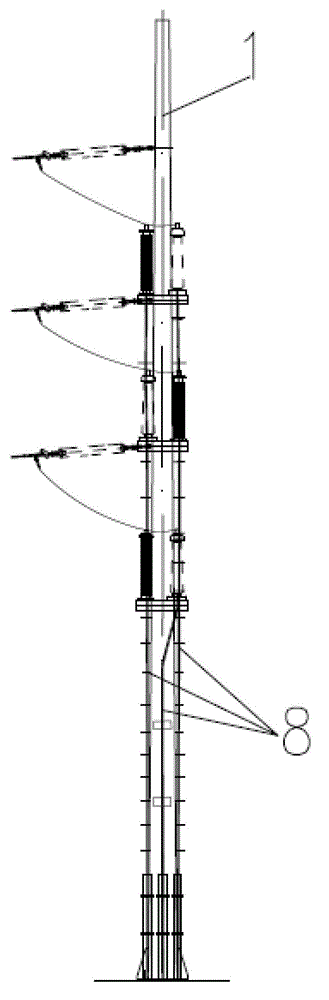

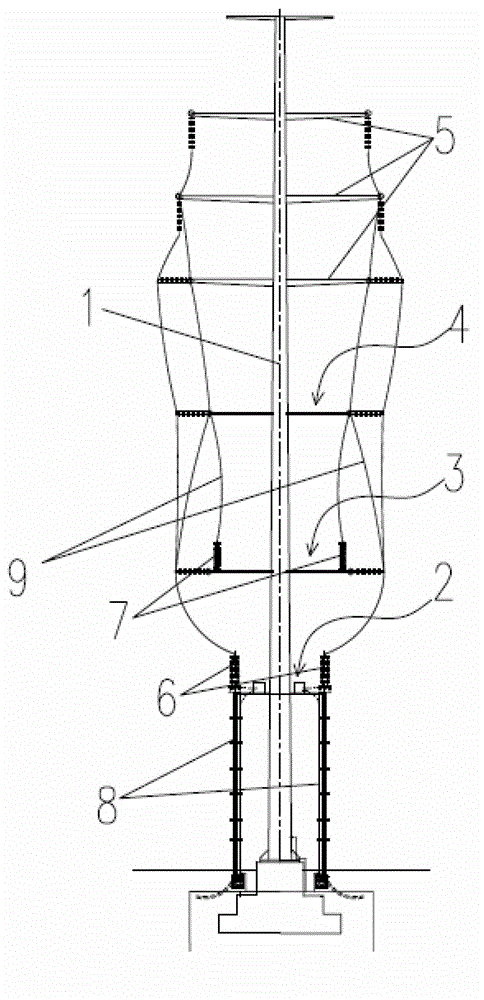

[0021] Such as image 3 and Figure 4 As shown, a steel pipe pole for a cable terminal in this embodiment includes a main pole 1 provided with a crossarm 5, a lightning arrester 7 and a cable terminal head 6, and also includes: a cable terminal bracket layer for centrally arranging the cable terminal head 6 2. The lightning arrester support layer 3 and the silicon rod support layer 4 are used to centrally set the lightning arrester 7, and the cable terminal support layer 2, the lightning arrester support layer 3, the silicon rod support layer 4 and several transverse rods are sequentially arranged on the main pole 1 from bottom to top. The rod 5 and the cable terminal head 6 are arranged on the cable terminal bracket layer 2, and the lightning arrester 7 is arranged on the lightning arrester bracket layer 3.

[0022] Specifically, as shown in the figure, the cable terminal steel pipe pole of this embodiment adopts 3 sets of crossarms 5, 6 cable terminal heads 6 and 6 lightnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com