Unbalanced shaft and method for producing same

A balance shaft, balancing technology, used in spring/shock absorber manufacturing, vibration suppression adjustment, springs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

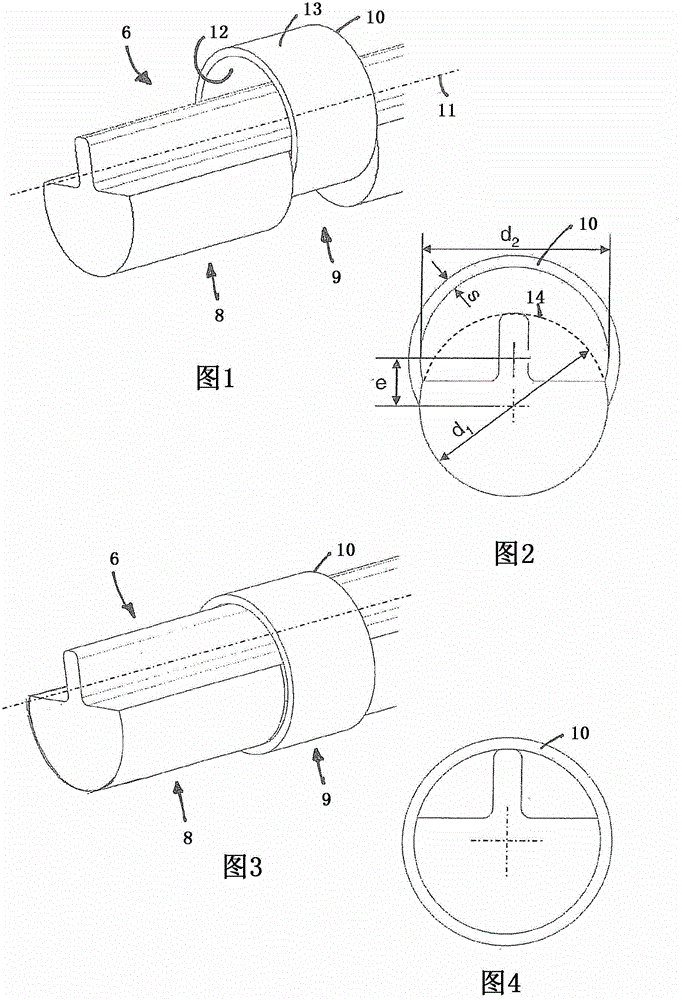

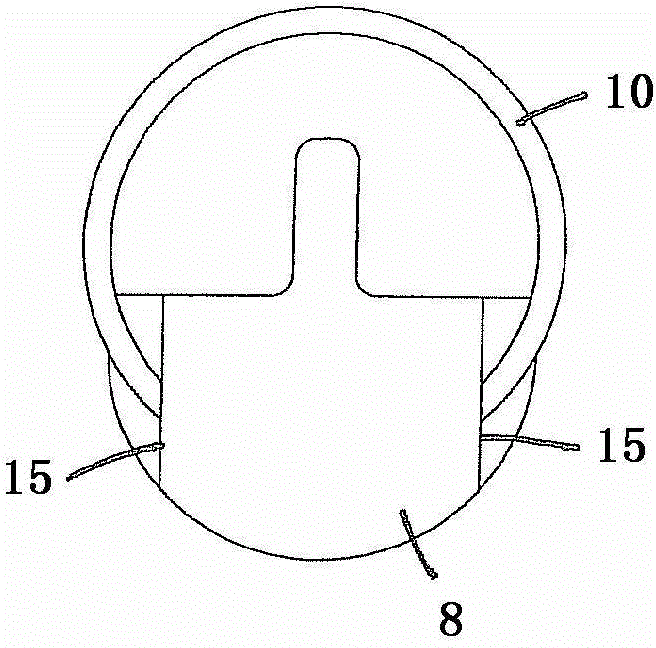

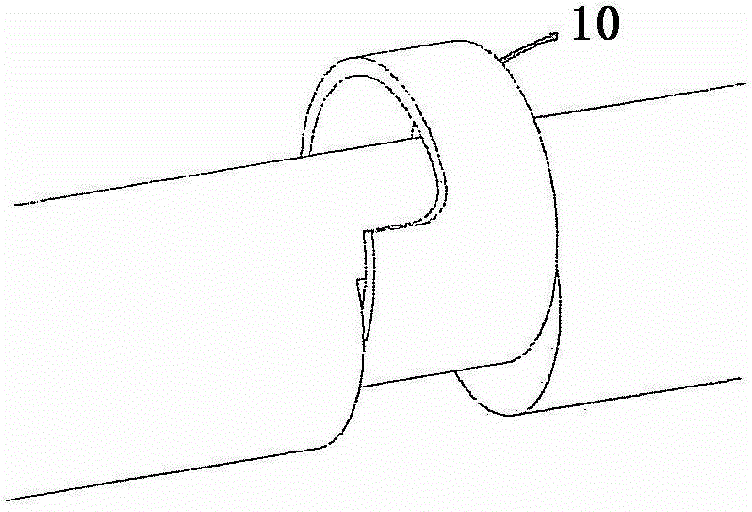

[0037] Should be attached Picture 12 At the beginning of the description of the present invention, the accompanying drawings combined with a schematic transmission diagram show a mass balance transmission of a reciprocating piston internal combustion engine in the form of a four-cylinder tandem structure, which is also known as Lancaster-Ausgleich. The internal combustion engine 1 includes a piston 2 oscillating in its cylinder, the longitudinal movement of which is converted into the rotation of a crankshaft 4 by a crank 3. This (here via the intermediate shaft 5) drives two unbalanced shafts 6 with an unbalanced 7, wherein the unbalanced shaft 6 is parallel to the crankshaft 4 and rotates in the opposite direction at a doubled crankshaft speed in order to compensate for the second-order free inertia force.

[0038] As explained below, the present invention provides an unbalanced shaft made of cast steel with a support made of hardened rolling bearing steel (such as model 100Cr6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com