Reusable sprue with temperature test head

A technology of temperature measuring head and pouring riser, which is applied in the field of aluminum alloy casting, can solve the problems of high cost, large consumption, and large waste, and achieve the effect of ensuring product quality and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

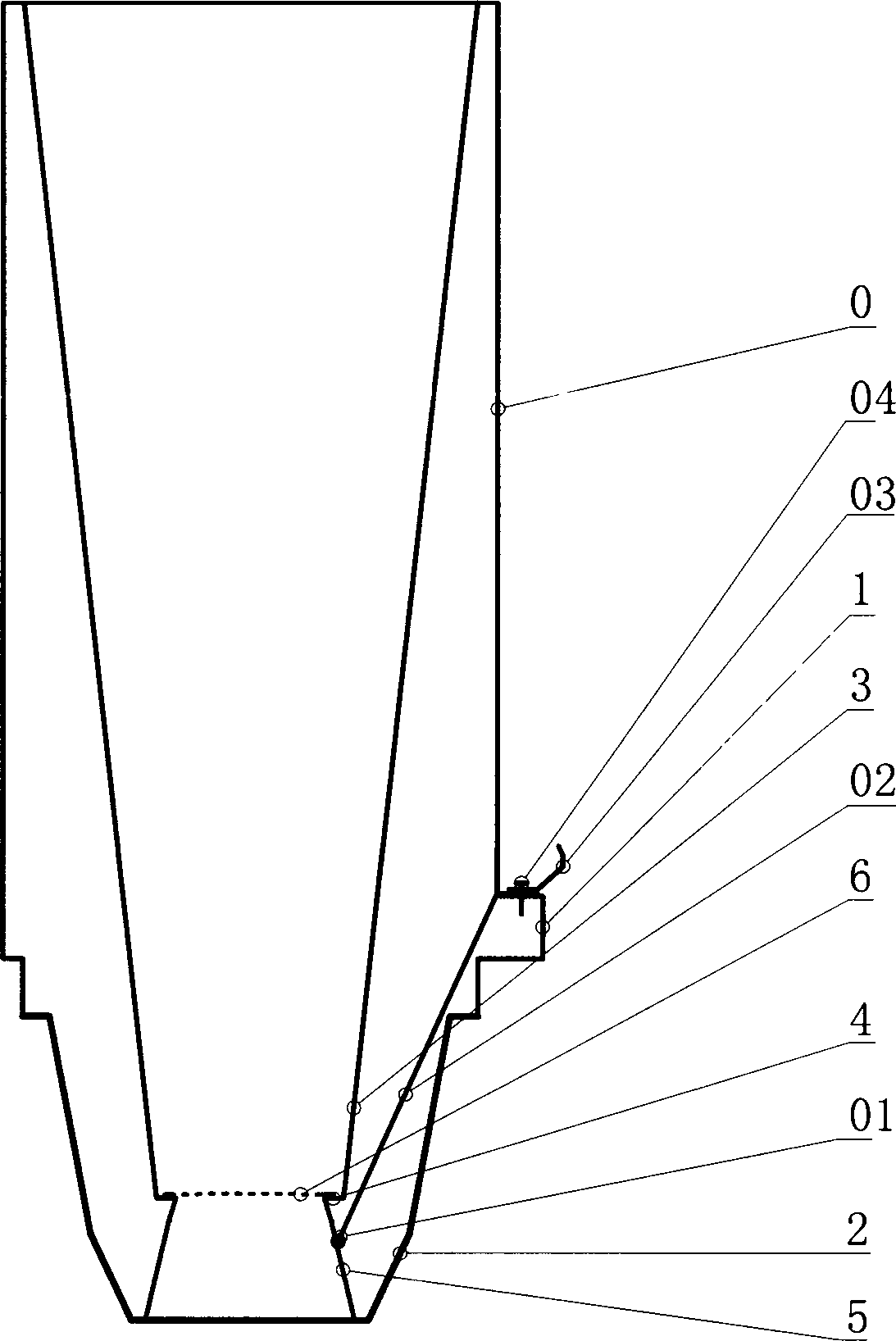

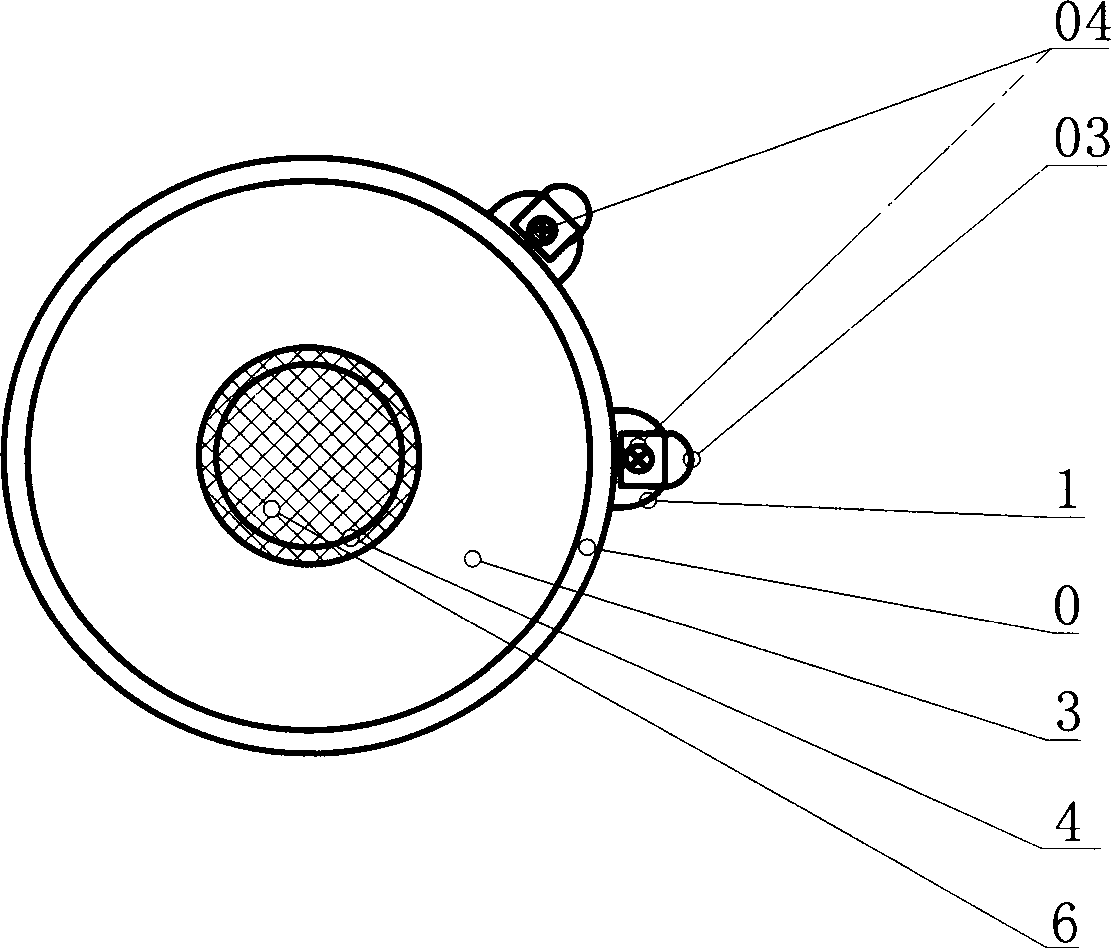

[0011] figure 1 , figure 2 Including the riser body 0, the positioning ear 1, the setting mold 2, the pouring cavity 3, the filter table 4, the gate 5, the filter screen 6, the temperature measuring head 01, the thermocouple wire 02, the metal shrapnel 03, and the screw 04 etc.

[0012] Such as figure 1 , figure 2 As shown, the present invention is a reusable pouring riser with a temperature measuring head.

[0013] The reusable pouring riser body 0 with a temperature measuring head is made of ceramic material. The pouring riser body 0 includes two positioning ears 1 arranged in the middle and lower part of the outside of the body. The lower part of the positioning ears 1 is provided with a shaping mold 2. The riser body 0 is provided with a through pouring cavity 3, the lower part of the pouring cavity 3 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com