Pretreatment method of crystal before being cut and fixed

A treatment method and crystal cutting technology, which can be applied to work accessories, stone processing equipment, manufacturing tools, etc., can solve the problems of crystal fixing and easy cracking, and achieve the effect of avoiding crystal cracking and reducing mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail according to the examples below.

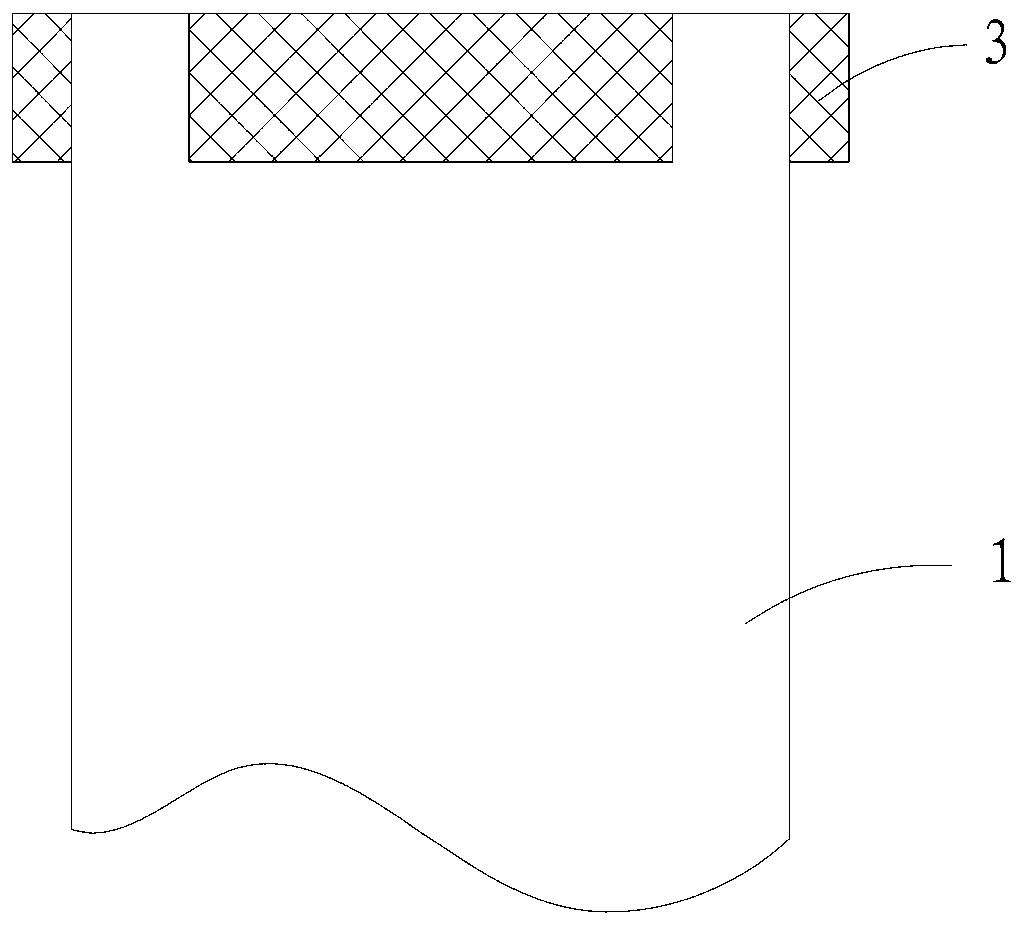

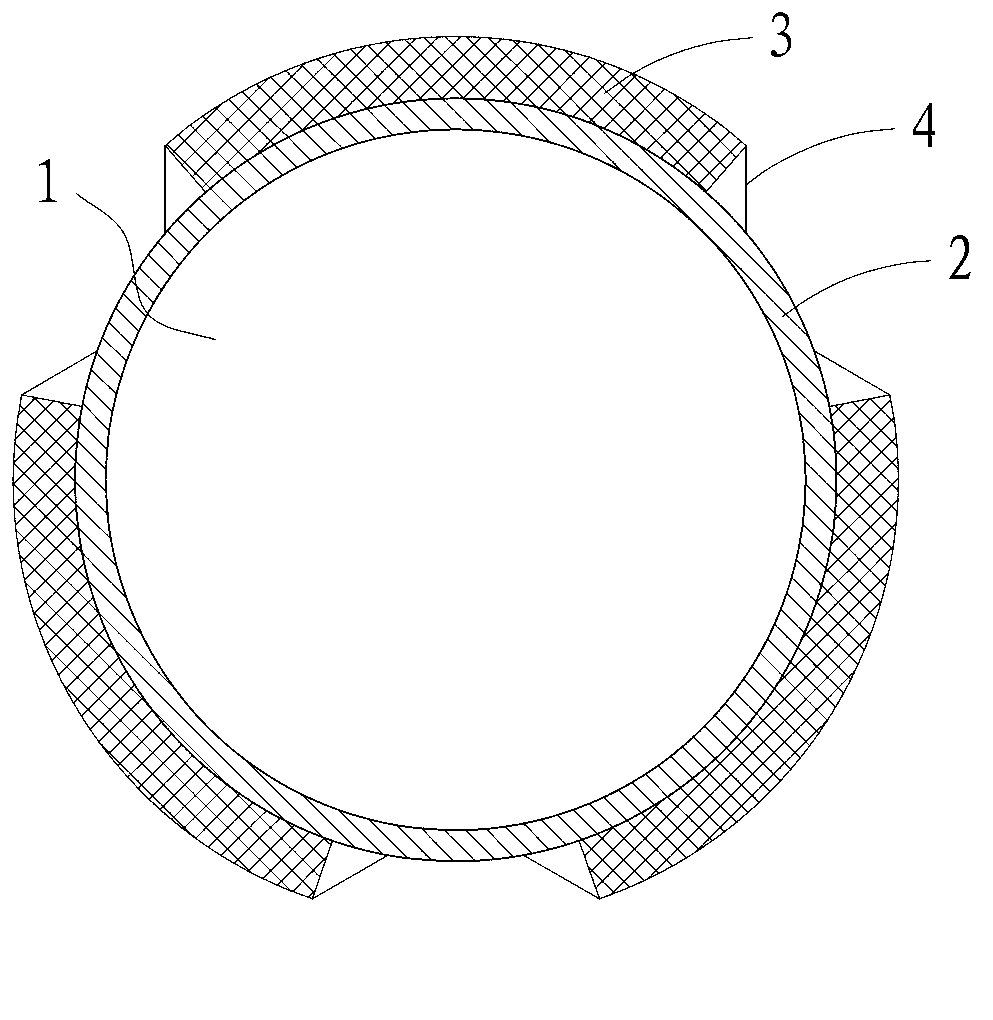

[0020] figure 1 The front view of the crystal after the pretreatment method is used for this implementation case, figure 2 For the top view of the crystal after the pretreatment method in this implementation case, refer to figure 1 , figure 2 , the present invention, the pretreatment method before crystal cutting and fixation, the steps include:

[0021] (1) Wrap the crystal 1 to be fixed with adhesive tape 2 for 2~3 layers. The maximum stretch rate of adhesive cloth 2 is 140%~160%, and the thickness of adhesive cloth 2 is 0.10~0.15mm;

[0022] (2) Three metal partitions 3 are symmetrically arranged at the fixed place of the above-mentioned crystal 1, and glued with adhesive tape 4. The above-mentioned metal partition 3 has an arc-shaped structure, and the radian of the arc surface matches the side of the above-mentioned crystal 1. The metal The partition 3 is set as a cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com