Process for coating film on sheet material

A process and sheet technology, which is applied in the field of film coating on sheets, can solve the problems of prolonged formation time, error, large space, etc., and achieve the effect of reducing micropores and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

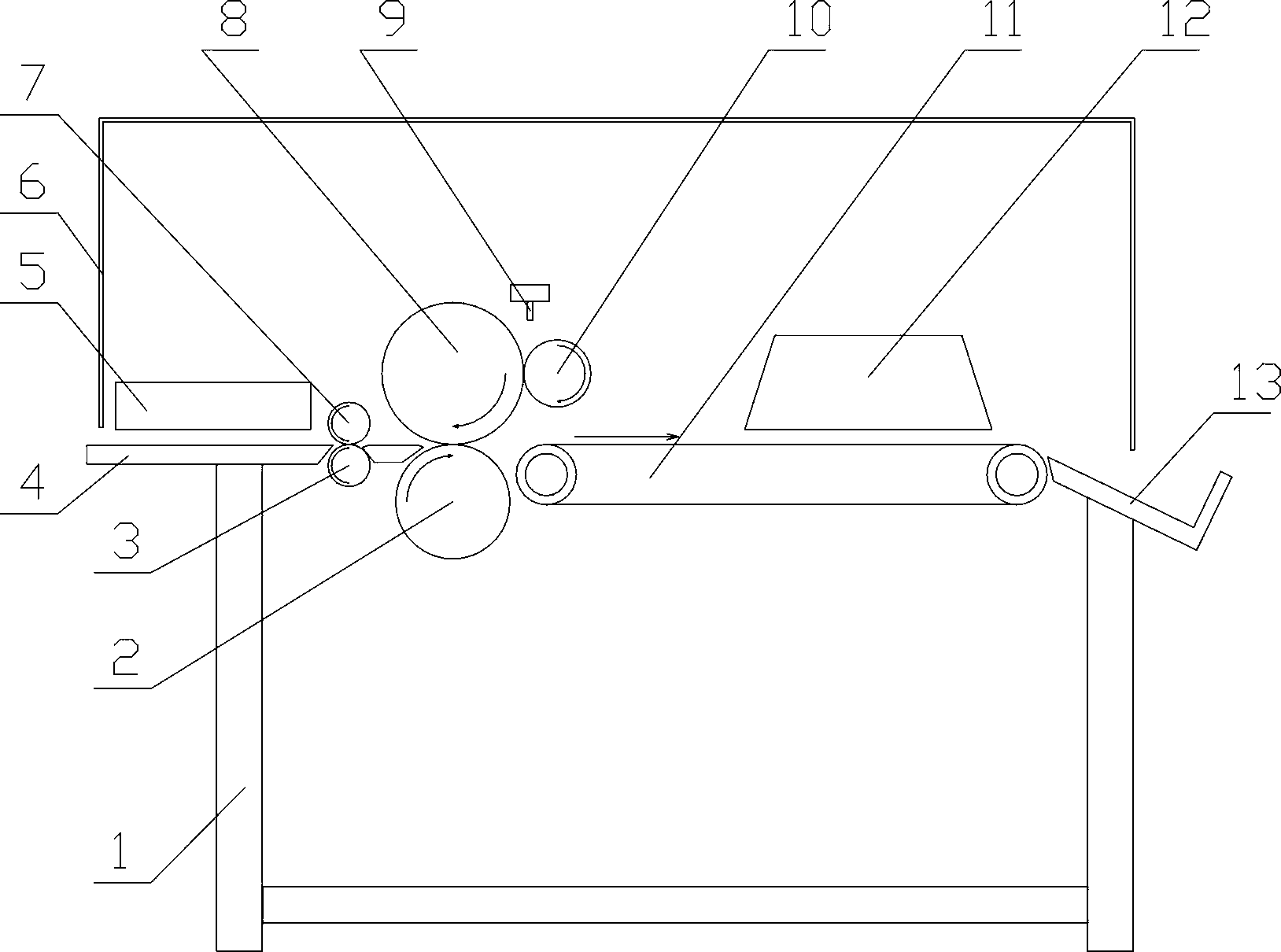

[0022] The invention is described in detail below in conjunction with the accompanying drawings:

[0023] refer to figure 1 , in this specific implementation process, the coating material is preheated by the auxiliary preheating device 5 before coating, and then driven by the lower feeding roller 3 and the upper feeding roller 7 to realize the advancement from left to right on the platform 4; A motor (not shown in the figure) drives the coating roller wheel 8 to rotate clockwise, and another motor (not shown in the figure) drives the material guide roller 2 to also rotate in the clockwise direction, and the coated roller 2 will be coated The material is brought between the material guide roller 2 and the coating roller 8; the medicinal liquid enters the coating rubber roller 8 through the injection port of the medicinal liquid tank 9, and is arranged between the medicinal liquid roller 10 behind the coating rubber roller 8; A motor (not shown in the figure) drives the medici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com