Composite grid structure reinforced concrete composite pile and its construction method

A composite material and network frame structure technology, which is applied in the direction of foundation structure engineering, sheet pile walls, manufacturing tools, etc., can solve problems such as peeling between materials, and achieve the effects of overcoming peeling between materials, easy forming, and improving the bite force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

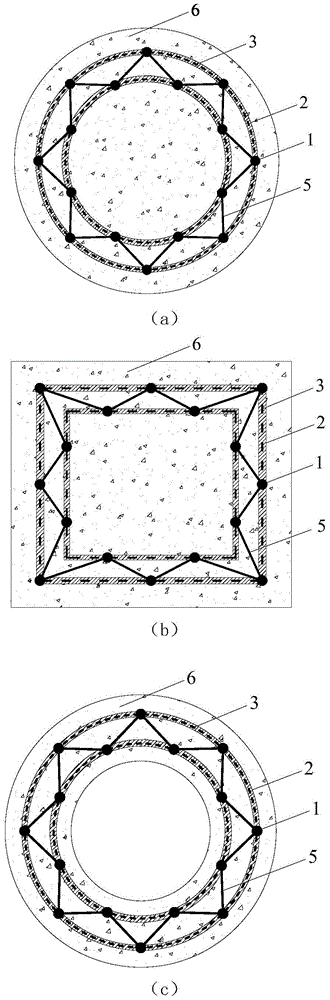

[0067] Take a circular section as an example:

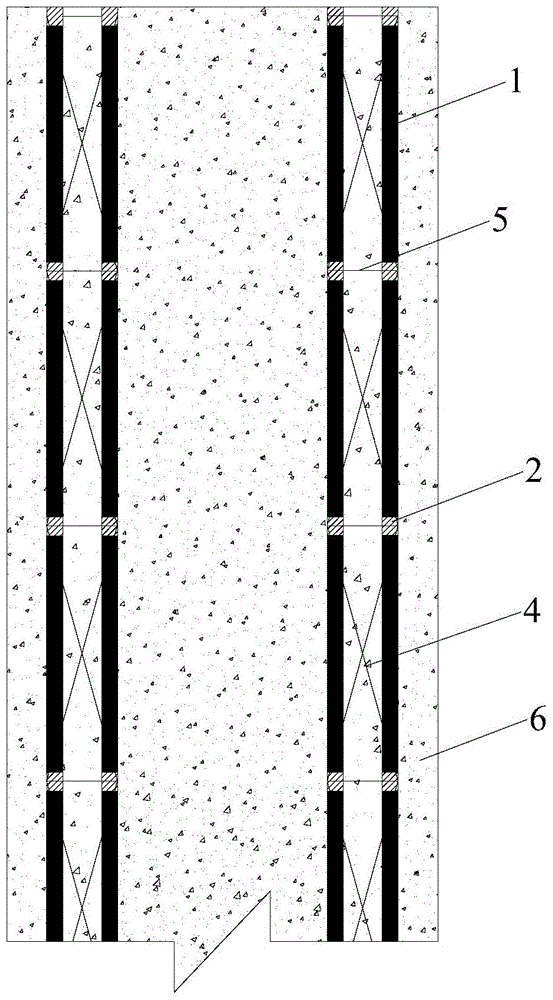

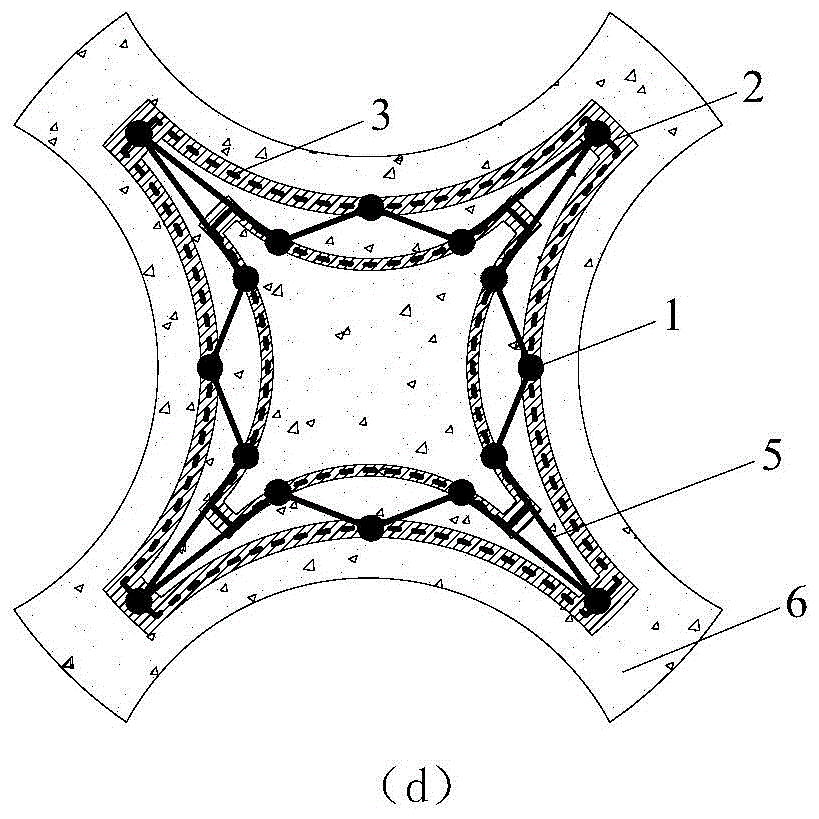

[0068] to combine figure 1 and figure 2 (a), a reinforced concrete composite pile with a composite grid structure, including a concrete pile 6 and two layers of composite material reinforcements arranged in the concrete pile 6, each layer of composite material reinforcements includes a longitudinal main reinforcement 1, a transverse reinforcement Main reinforcement 2 and oblique abdominal reinforcement 3, 8 longitudinal main reinforcements 1 are symmetrically arranged on the concrete pile section, 15 transverse main reinforcements 2 are arranged at longitudinal intervals along the longitudinal The hoop is integrated into a whole, and a curved quadrilateral is formed between two adjacent transverse main ribs 2 and two adjacent longitudinal main ribs 1 connected thereto, and oblique abdominal ribs 3 are arranged on the diagonals of the quadrilateral.

[0069] to combine Figure 4 , also includes longitudinal webs 4 and transver...

Embodiment 2

[0087] Take the X-shaped section as an example

[0088] to combine figure 1 and figure 2 (b), a reinforced concrete composite pile with a composite grid structure, including a concrete pile 6 and two layers of composite material reinforcements arranged in the concrete pile 6, each layer of composite material reinforcements includes a longitudinal main reinforcement 1, a transverse reinforcement The main reinforcement 2 and the diagonal reinforcement 3, and the 8 longitudinal main reinforcements 1 are symmetrically arranged on the concrete pile section according to the shape of the concrete pile section, and the 20 horizontal main reinforcements 2 are arranged at longitudinal intervals along the longitudinal , the horizontal main reinforcement and the oblique abdominal reinforcement are integrally formed), the eight longitudinal main reinforcements 1 are hooped into a whole, and the two adjacent horizontal main reinforcements 2 and the two adjacent longitudinal main reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com