Gob-side entry retaining method reserving shed legs for filling

A technology of retaining an empty roadway and retaining sheds, which is applied in the direction of filling, earthwork drilling, safety devices, etc., which can solve the problems of insufficient filling, difficult maintenance, and increased procedures, so as to maintain bearing capacity, wide practicability, and complete protection sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] The gob-side retaining method for filling with retaining shed legs of the present invention includes mining roadways supported by U-shaped sheds, and the specific operation steps are as follows:

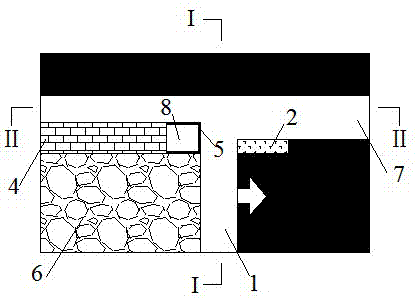

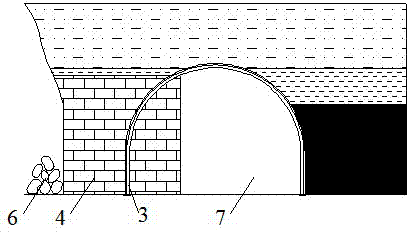

[0019] (1) Open the gap in advance: such as figure 1 As shown, at the end of the coal mining face 1, a gap 2 is made along the advancing direction of the working face by manual or small roadheader. The length of the gap 2 is 6m~10m, and the U-shaped shed leg 3 in the roadway , in the gap 2 area, the roof is supported by the anchor beam net according to the conventional method; the gap 2 is opened in advance, and the width of the gap 2 should be greater than the width of the designed filling wall 4 in the goaf 6, so as to ensure that the mining The coal machine will not cut the U-shaped shed leg 3 when cutting coal;

[0020] (2) Manual formwork: along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com