Suitability evaluation method of high-strength materials for soft and strong double-layer composite support beside gob-side entry retaining

A double-layer composite and evaluation method technology, which is applied in the direction of earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problem of inaccurate strength of roadside filling body, waste, and failure to consider the change in the bearing capacity of filling body and goaf gangue And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in further detail below by way of examples.

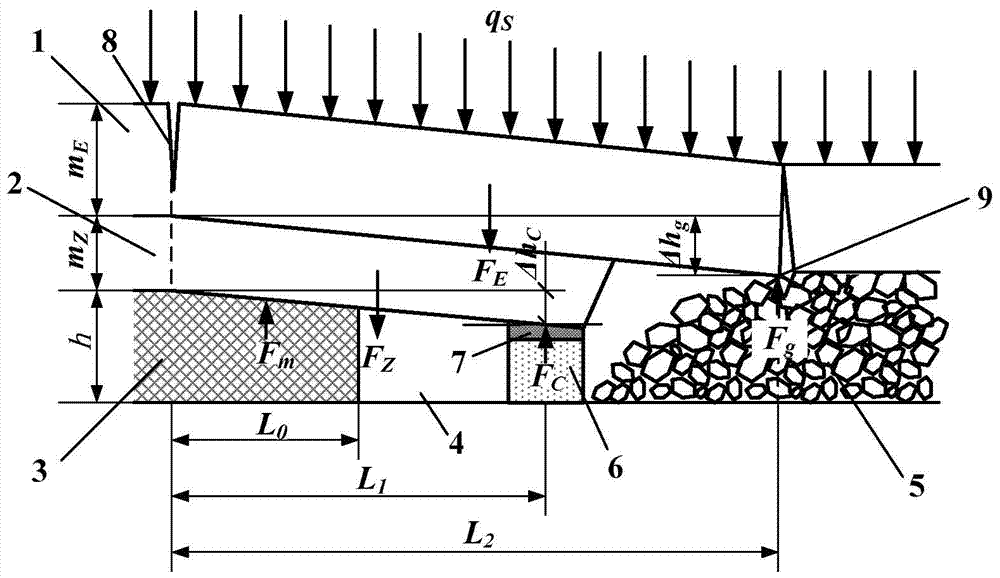

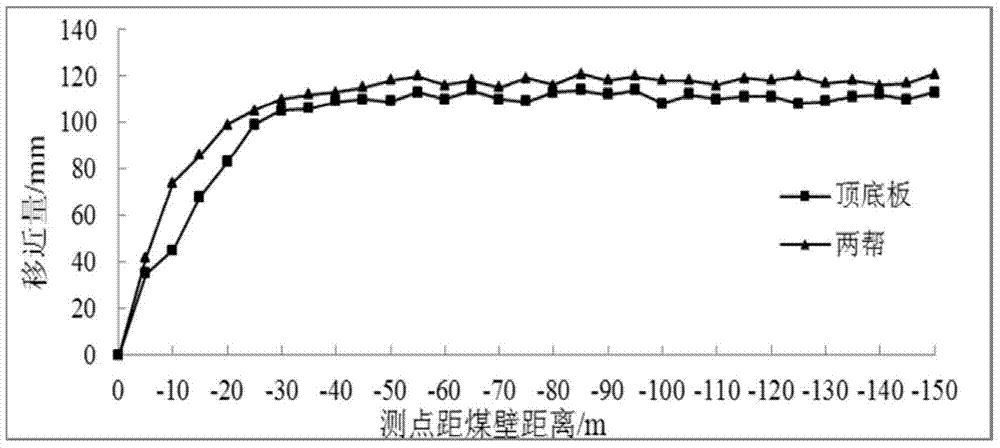

[0071] The transportation roadway of the 8213 working face of a mine adopts the technology of retaining the roadway along the goaf, and adopts the soft and strong double-layer composite support method beside the roadway, among which:

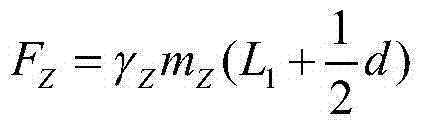

[0072] The average mining height h of coal seam 3 is 1.8m, and the immediate roof 2 is interbedded with sandy mudstone and mudstone, cemented by mud, with an average thickness of m Z is 5.2m, the average bulk density γ Z is 25kN / m, and the suspended roof is very small; the basic roof 1 is interbedded with siltstone and fine sandstone, cemented with mud, with an average thickness of m E is 9.3m, the average bulk density γ E is 27kN / m, the average breaking step distance L 2 is 20.4m; the top of the basic roof 1 is interbedded with coarse sandstone and mudstone, with low strength, and moves simultaneously with the basic roof 1, with an average thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com