Motor vehicle body with plasma-treated gluing surface for attachment of seal

A technology for motor vehicles and adhesive surfaces, which is applied in the direction of mechanical equipment, vehicle parts, engine components, etc., can solve quite expensive problems, achieve the effect of improving adhesion and reducing manufacturing and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

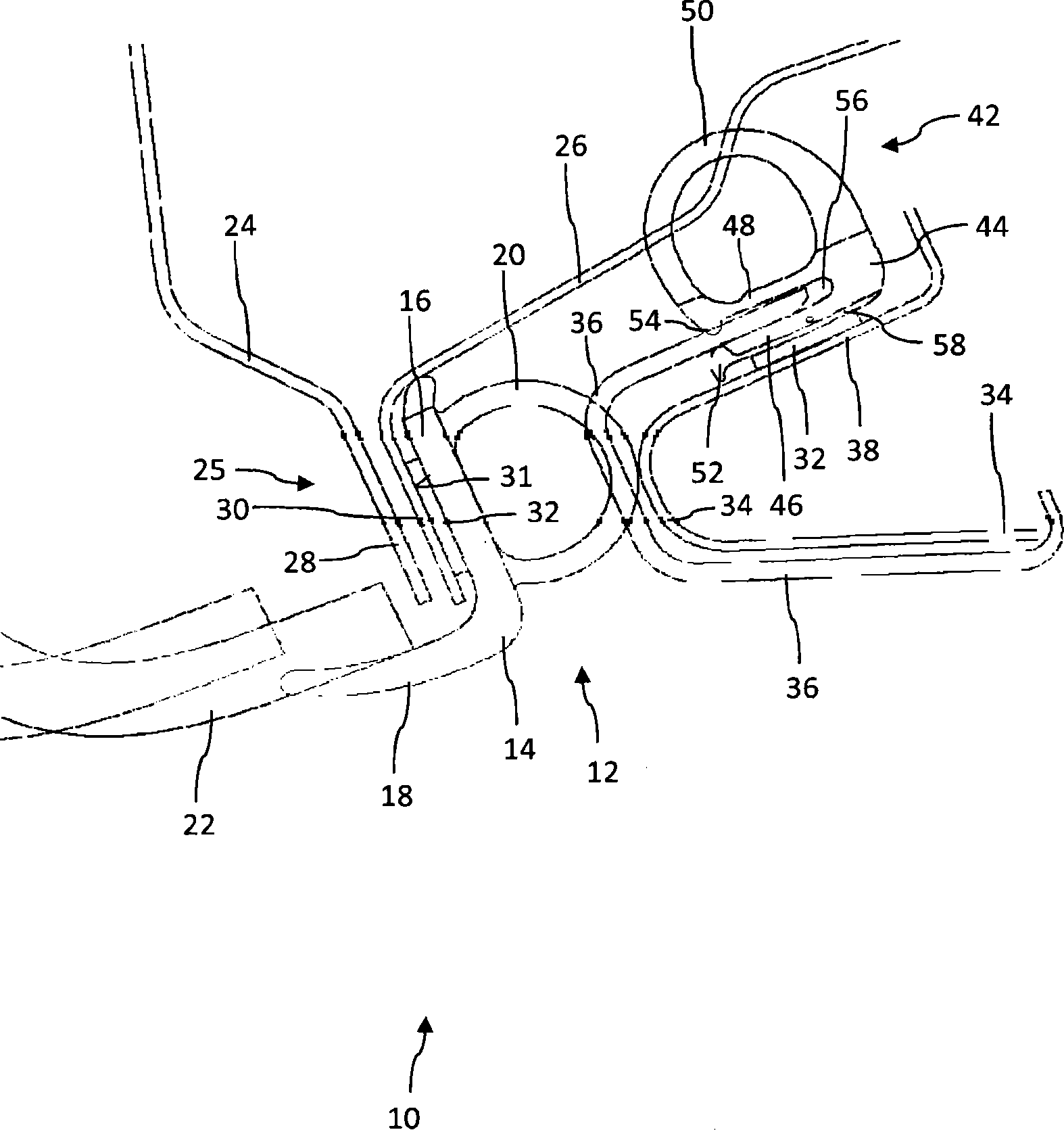

[0030] attached figure 1 Shown is a sectional view of a sealing device 10 which has a total of two seals 12 , 42 which are designed as primary and secondary seals, for example for sealing a door gap in a motor vehicle body. The motor vehicle body has two body steel sheets 24, 26 adjoining the edge section to be sealed, and these body panels 24, 26 form the edge section 25 together with flange sections 28, 30 designed to cooperate with each other. The main seal 12 is attached to this edge section 25 , for example by adhesive bonding.

[0031] The seal 12 has an approximately L-shaped fastening section 14 and a hollow-shaped sealing section 20 . In this case, the fastening section 14 and the sealing section 20 can be produced from different plastic or rubber-based materials, it being advantageous for the sealing section 20 to have a higher elasticity than the fastening section 14 .

[0032] The fastening section 14 has a fastening leg 16 which is adhesively fastened by means o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com