Low-rotating-speed double-layer propcopter

A propeller, low-speed technology, applied in the field of aviation helicopters, can solve the problems of large engine wear, short service life and high manufacturing cost, and achieve the effects of low cost, long service life and improved power utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

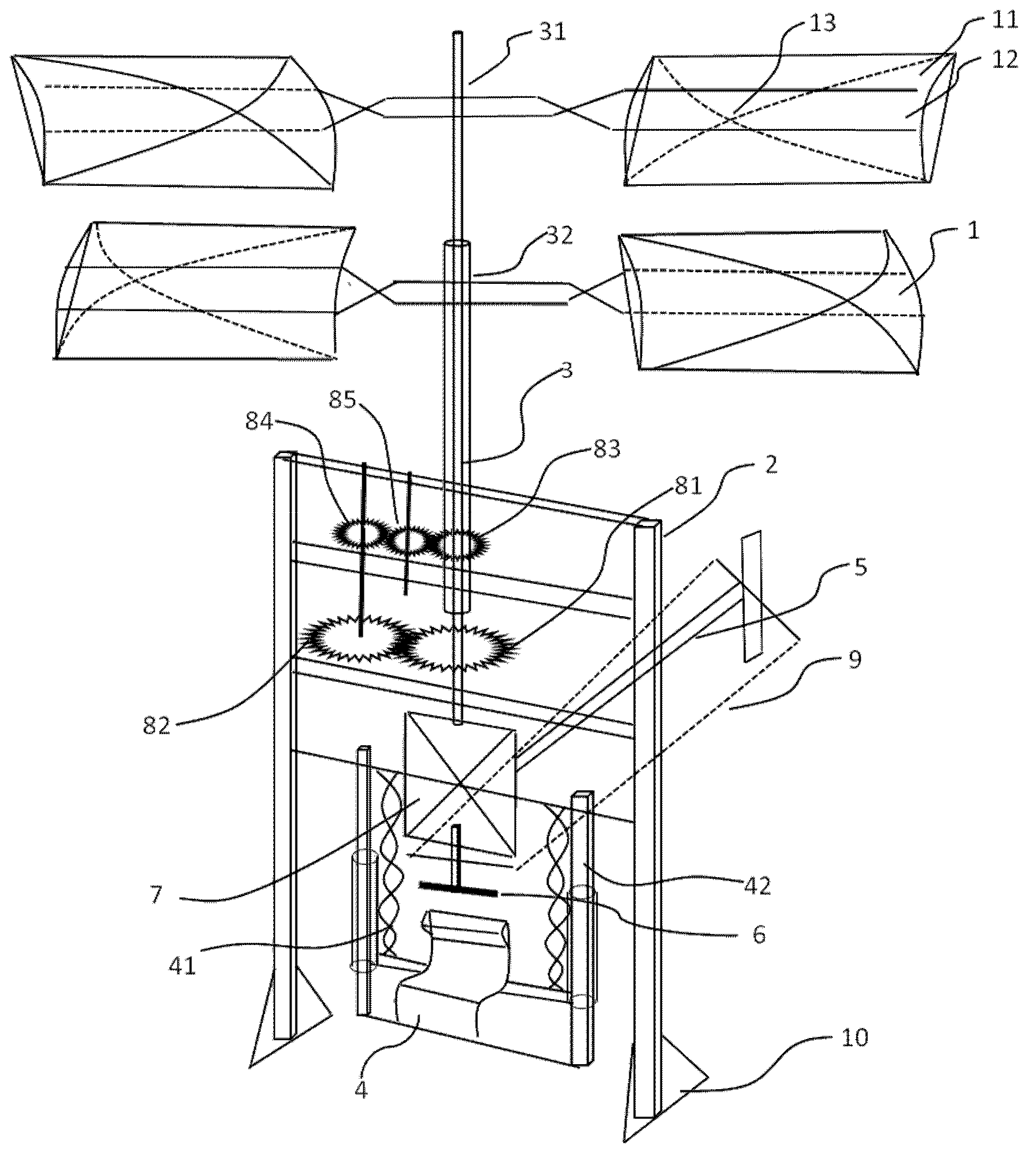

[0022] Low speed double deck propeller helicopters, such as figure 1 As shown, it includes a frame 2 and a propeller 1 , the propeller 1 is installed on a central shaft 3 , and the central shaft 3 is mounted on the frame 2 .

[0023] The central shaft 3 includes a first rotating shaft 31 and a second rotating shaft 32 , and the second rotating shaft 32 is sleeved on the outside of the first rotating shaft 31 . The upper propeller is installed on the upper end of the first rotating shaft 31 , and the lower propeller is installed on the upper end of the second rotating shaft 32 .

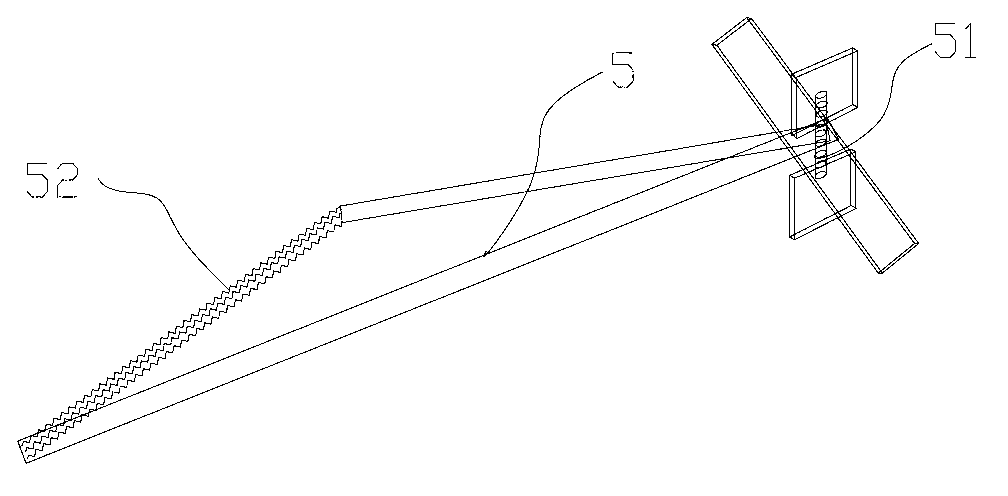

[0024] combine figure 1 , image 3 , Figure 4 and Figure 5 , the propeller 1 is provided with two layers, namely an upper layer propeller and a lower layer propeller. The propeller includes two blades 11 , and the two blades 11 are respectively arranged on both sides of the central shaft 3 through a connecting rod 12 . The lower surface of the blade 11 is provided with a concave structure 13. ...

Embodiment 2

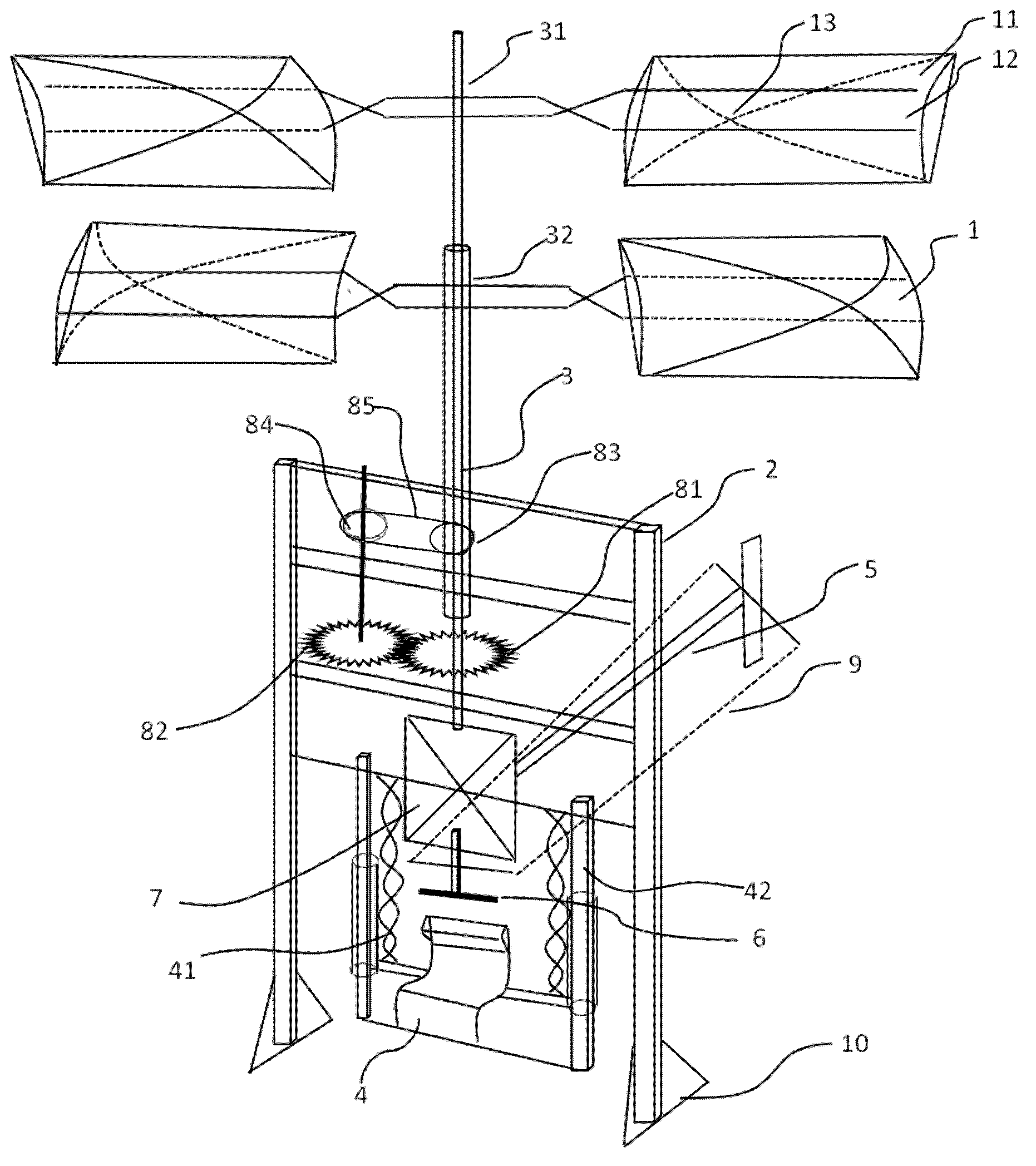

[0031] Low speed double deck propeller helicopters, such as figure 2 As shown, the basic structure is the same as that of Embodiment 1, except that the rotation direction of the upper propeller is controlled opposite to that of the lower propeller. The implementation of this embodiment is: the third gear and the fourth gear in Embodiment 1 are replaced by the first pulley 83 and the second pulley 84, the fifth gear is removed, and the first pulley 83 and the second pulley 84 The transmission belt 85 is put on the top, and the first gear 81 is driven by the engine 7. The rotation of the first gear 81 drives the second gear 82, and the rotation of the second gear 82 drives the second gear coaxial with it. Belt pulley 84 rotates, and because of the transmission effect of described transmission belt 85, then drives first belt pulley 83 to rotate and finally drives second rotating shaft 32 to rotate, has realized that the direction of rotation of the upper propeller and the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com