Automatic sectional material storage device

An automatic storage and profile technology, which is applied in the direction of coiling, transportation and packaging, and thin material processing, etc., can solve the problems of profile confusion, poor operating conditions at the splicing site, and high requirements for operating skills, and achieve the effect of ensuring appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

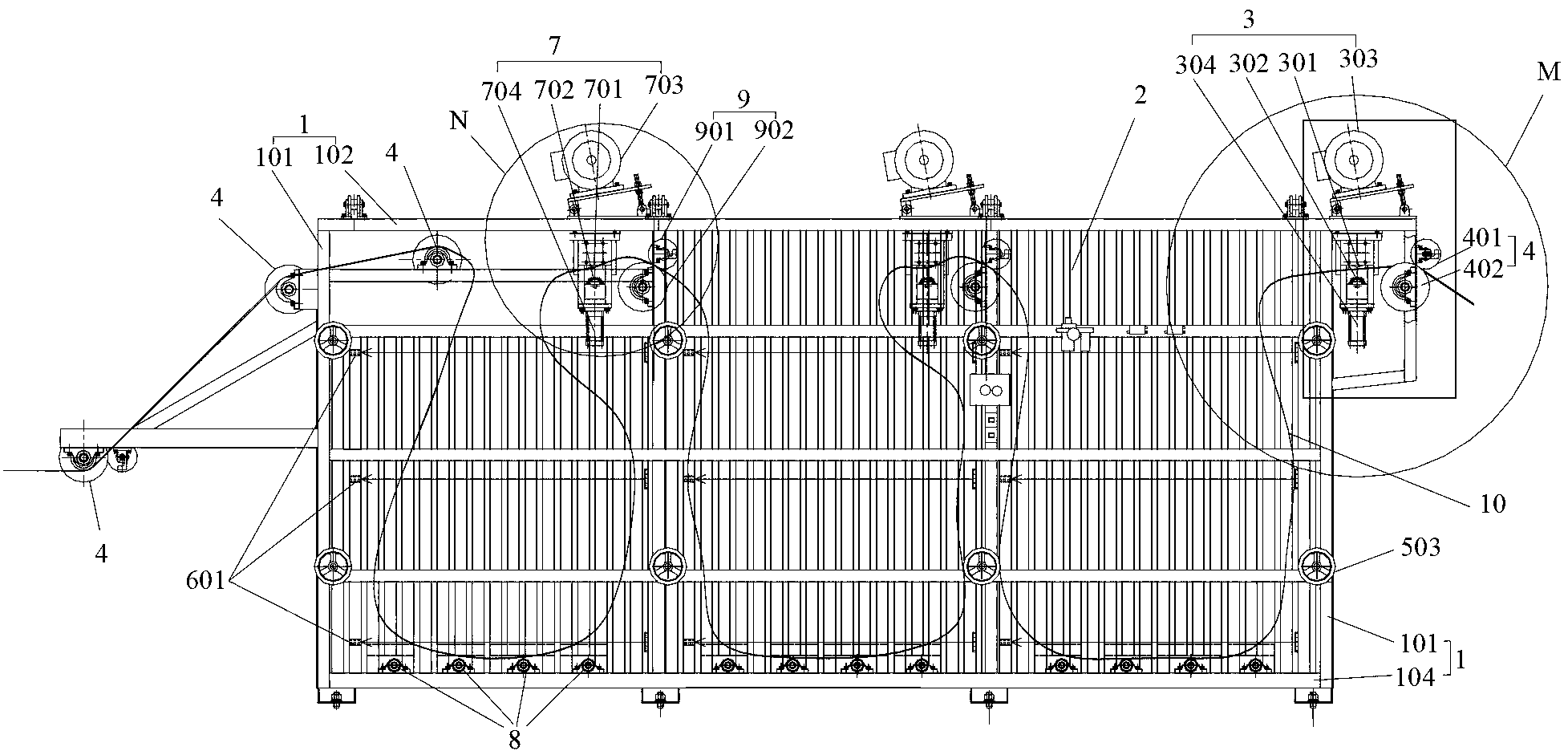

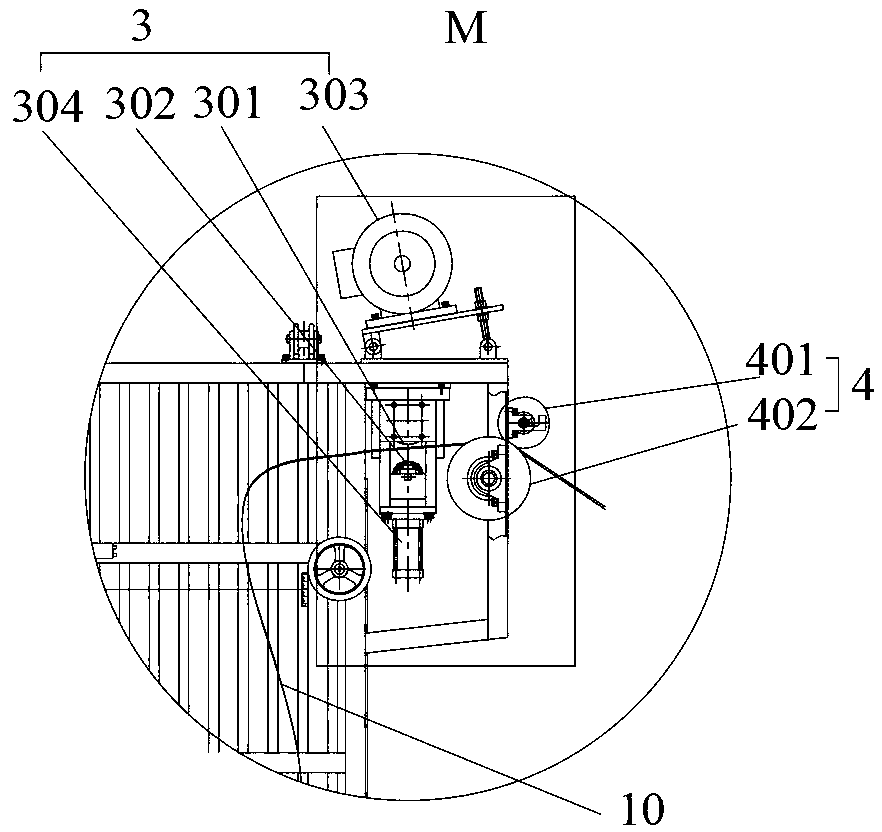

[0038] Embodiment 1, as figure 2 , 5 As shown, the present embodiment is an independent integral device, and the profile automatic storage device includes an enclosed main frame body 1, and the main frame body 1 is provided with a storage mechanism for storing profiles, and the storage mechanism is included in the main frame body The space between two adjacent partitions 2 is a storage tank 201 for storing profiles, and at least one of the partitions 2 can be moved to adjust the width of the storage tank 201; Corresponding to each of the storage tanks 201, the main frame body 1 is provided with a conveying mechanism 3 for conveying profiles into the storage tank 201; the main frame body 1 is also provided with a control mechanism, and the control mechanism includes a main controller ( Not shown in the figure), a plurality of sensors 601 for detecting profiles are set at different positions in the storage tank 201, and the main controller is respectively connected with the se...

Embodiment 2

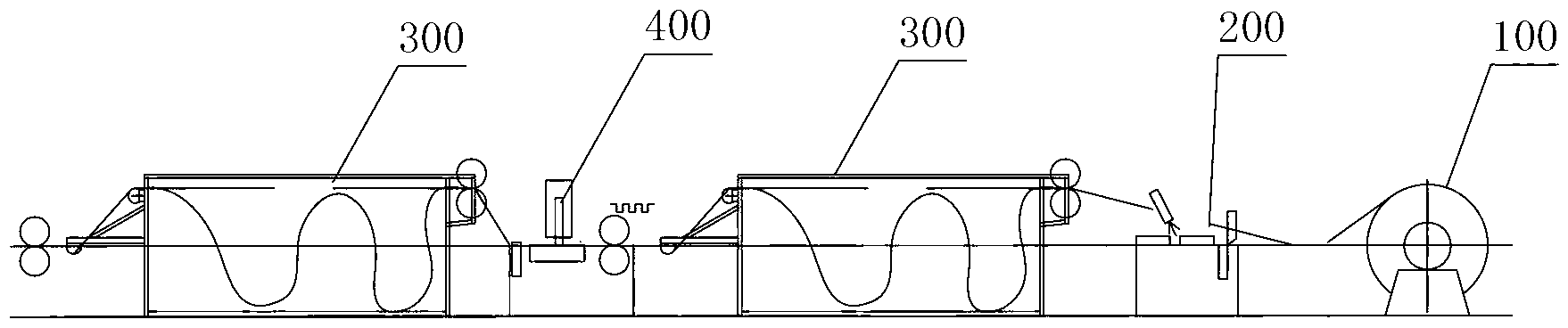

[0067] Embodiment 2 is the embodiment of the second profile automatic storage device. This embodiment is some adjustments made on the basis of Embodiment 1, and the structure and function of its main components are the same as Embodiment 1. Embodiment 2 is essentially a series connection device, which can adjust the number of series connections and adjust the length of the entire automatic storage device for profiles according to the storage capacity of profiles and the requirements of the transport speed of profiles.

[0068] The profile automatic storage device includes an enclosed main frame body, which is provided with a storage mechanism for storing profiles, a delivery mechanism for transporting profiles into the storage mechanism, and a control mechanism for controlling the action of the delivery mechanism.

[0069] The storage mechanism includes a long storage tank formed by at least two series-connected storage tanks; the number of series connection is determined accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com