Equipment and process for producing sulphuric acid by utilizing calcium sulphate

A calcium sulfate and sulfuric acid technology, applied in the direction of sulfur compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of easy dead angle, insufficient reaction and high cost in the reaction stage, and achieve the promotion of reaction uniformity, forced disturbance, and continuity. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

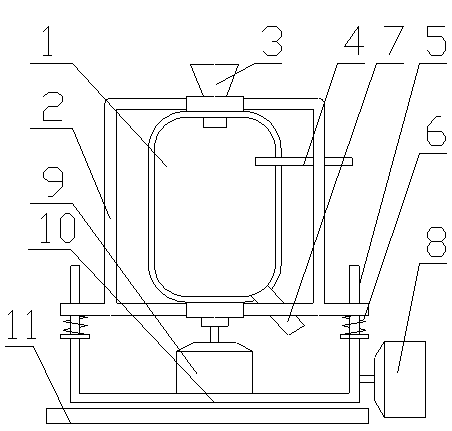

[0012] With reference to accompanying drawing, the equipment that utilizes calcium sulfate to produce sulfuric acid of the present embodiment comprises calcining kiln 1, support 2, hopper 3, exhaust port 4 and discharge port 7, is also provided with guide post 5, driving seat 10, longitudinal exciter Vibrator 9, transverse vibrator 8, horizontal slide rail 11, the calciner 1 is fixed inside the support 2, and can move together with the support 2; the guide post 5 is 3, evenly distributed on the drive seat 10 , and is fixedly connected with the drive base 10 to form an integral body, the guide post 5 is connected to the support 2 through the damping spring 6, and supports the weight of the entire support 2; the longitudinal vibrator 9 is fixed on the drive base 10 and connected to the support 2 connected; the transverse vibrator 8 is directly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com