Moving bed type purification tank

A technology of moving bed type and purification tank, which is applied in the field of environmental engineering sewage treatment, and can solve problems such as non-directional movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

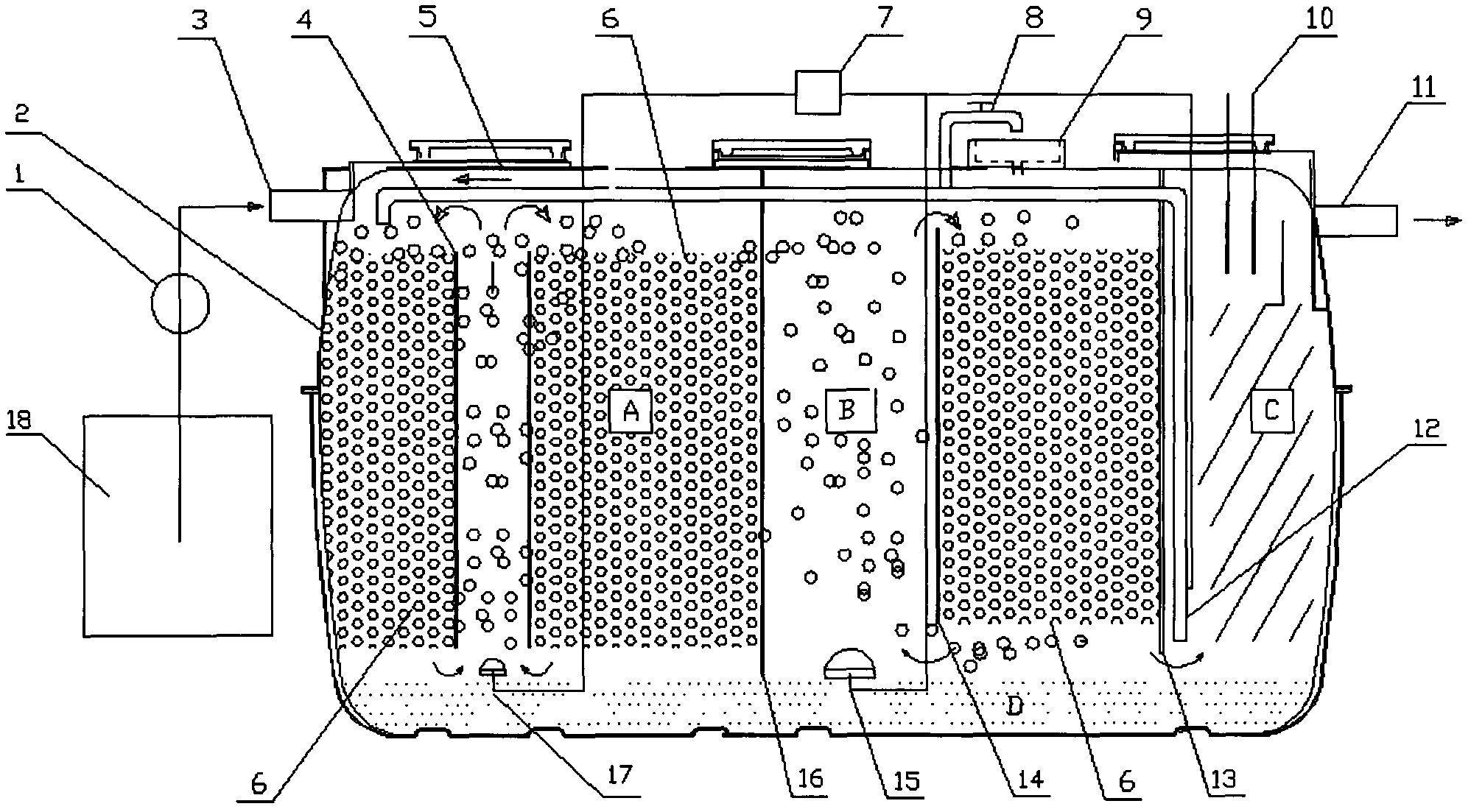

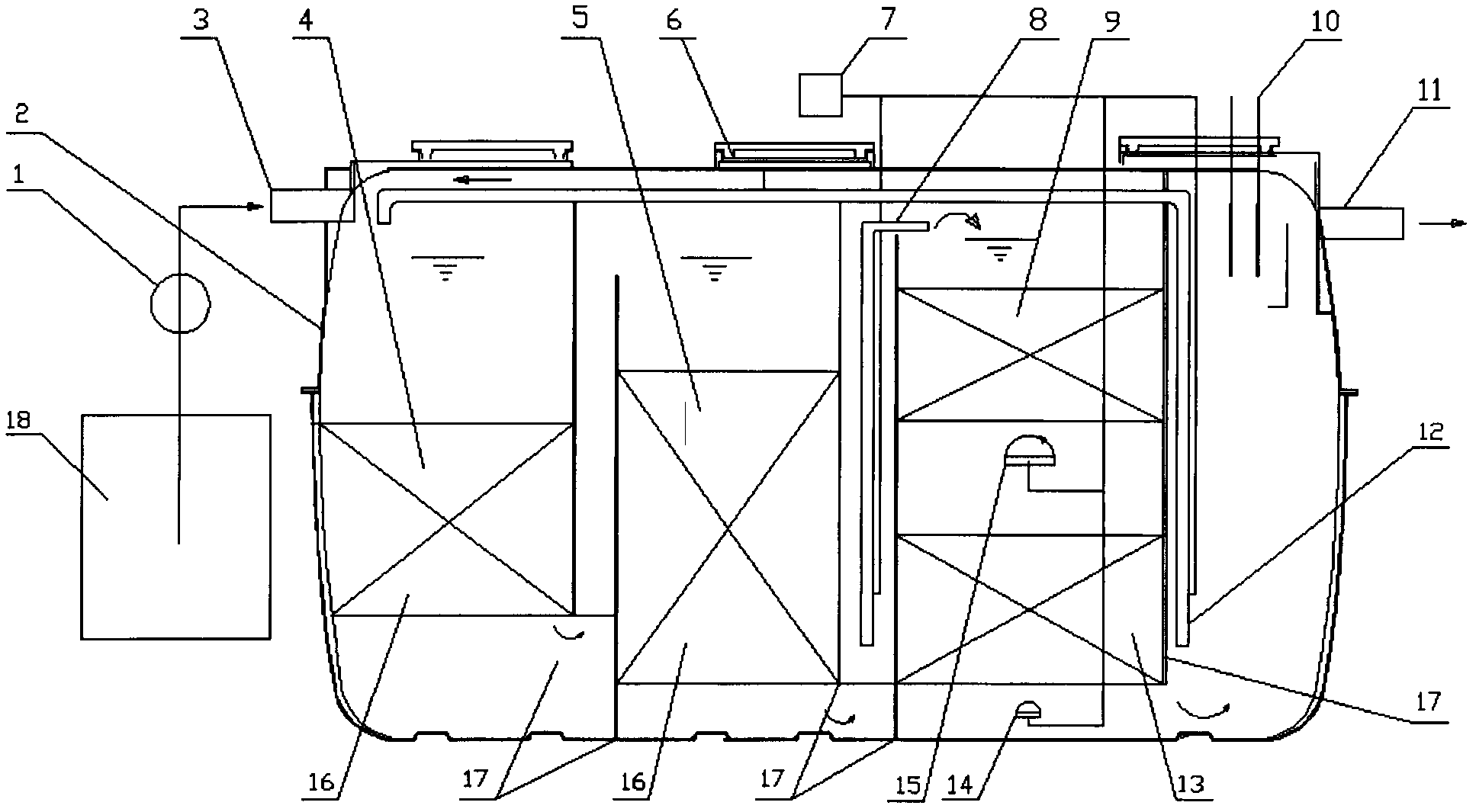

[0016] The sewage is collected by the collection tank 18 . In the collection tank 18 , the sediments and floating objects in the raw sewage are separated, and the intake pump 1 quantitatively lifts a certain amount of sewage from the water inlet 3 into the tank body 2 .

[0017] The anaerobic zone A is filled with suspended fillers 6 . The specific gravity of the suspended filler is 0.92 to 0.98. The principle of determining the specific gravity of the suspended filler is that the filler can always remain in a suspended state and will not sink during the operation process after the microorganisms hang on the film. In a static water body, the suspended fillers are densely crowded and arranged below the water level. The upper edge of the aeration cylinder 4 is lower than the horizontal by a certain distance, for example, 5-10 cm. The lower edge of the aeration cylinder 4 is higher than the bottom line of the packing layer by a certain distance, for example, 5-10 cm. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com