High-temperature water scale inhibitor as well as preparation method and application thereof

A technology of scale inhibitor and high-temperature water, which is applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., and can solve problems such as adverse effects and decreased stability of metal carboxylates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

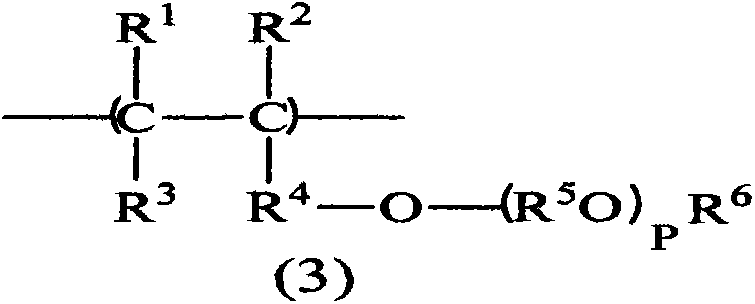

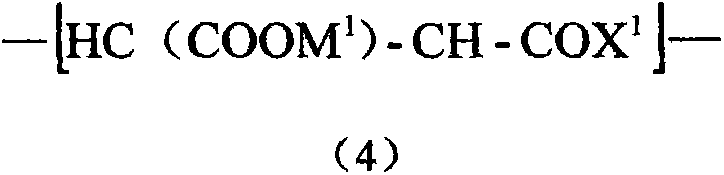

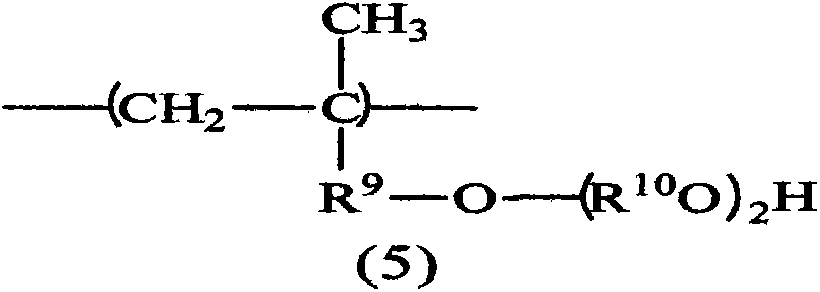

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: Production of high temperature water scale inhibitor X

[0055]A four-port glass reactor equipped with a thermometer, a stirrer, a dropping funnel and a reflux condenser, into which 25mL of distilled water, 50g of The unsaturated alcohol and 16g of maleic acid produced by the addition reaction raised the temperature of the reactor to 70°C. Add 1.0 g of sodium persulfate dissolved in 15 mL of distilled aqueous solution dropwise into the reactor within 240 min. The temperature in the reactor was maintained at 70° C. for 60 minutes to complete the polymerization reaction, and a polymer was obtained, which was an aqueous solution of high-temperature water scale inhibitor (I-1). The weight-average molecular weight of the polymer was 35,000.

Embodiment 2

[0056] Embodiment 2: Production of antiscalant Y for high temperature water

[0057] A four-port glass reactor equipped with a thermometer, a stirrer, a dropping funnel and a reflux condenser, into which 130mL of ion-exchanged water, 50g of - unsaturated alcohol produced by alcohol addition reaction, 20.0 g of maleic acid, the temperature of the reactor was raised to 65°C. Within 200 min, 100 mL of ion-exchanged aqueous solution in which 1.0 g of sodium persulfate was dissolved was dropped into the reactor. The temperature in the reactor was maintained at 65° C. for 60 minutes to complete the polymerization reaction, and a polymer was obtained, which was an aqueous solution of the high-temperature water scale inhibitor (I-2). The weight-average molecular weight of the polymer was 24,600.

Embodiment 3

[0058] Embodiment 3: the production of cement dispersant Z

[0059] A four-port glass reactor equipped with a thermometer, a stirrer, a dropping funnel and a reflux condenser, in which 160g of ion-exchanged water, 50g of ethylene oxide and 3-methyl-3-butene-1 - unsaturated alcohol produced by alcohol addition reaction, 15.0 g of maleic acid, the temperature of the reactor was raised to 60°C. Within 180 min, 100 mL of ion-exchanged aqueous solution in which 1.0 g of sodium persulfate was dissolved was dropped into the reactor. The temperature in the reactor was maintained at 60° C. for 60 minutes to complete the polymerization reaction, and a polymer was obtained, which was an aqueous solution of the high-temperature water scale inhibitor (I-3). The weight-average molecular weight of the polymer was 18,400.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com