General corrosion and scale inhibitor for purifying circulating water and preparation and application thereof

A technology of corrosion and scale inhibitors and clean circulating water, which is applied in the directions of descaling and water softening, chemical instruments and methods, complexes/solubilizing agents, etc. Water quality is easy to change and other problems, to achieve the effects of insensitive response to water quality changes, less dosing, and good corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Corrosion and scale inhibitor ingredients: 38% polyepoxysuccinate (PESA) 30%, 50% hydroxyethylidene diphosphonic acid (HEDP) 10%, 94% zinc sulfate heptahydrate 6%, 30% solid content 3% of sodium polyacrylate, 5% of benzotriazole (BTA), and the rest of water.

[0035] The preparation method is: add hydroxyethylidene diphosphonic acid and water into the reaction kettle, control the temperature at 45°C, then add polyepoxysuccinate, zinc sulfate, sodium polyacrylate, and benzotriazole in sequence in proportion After stirring at 50°C for 30 minutes, a clear amber liquid was obtained.

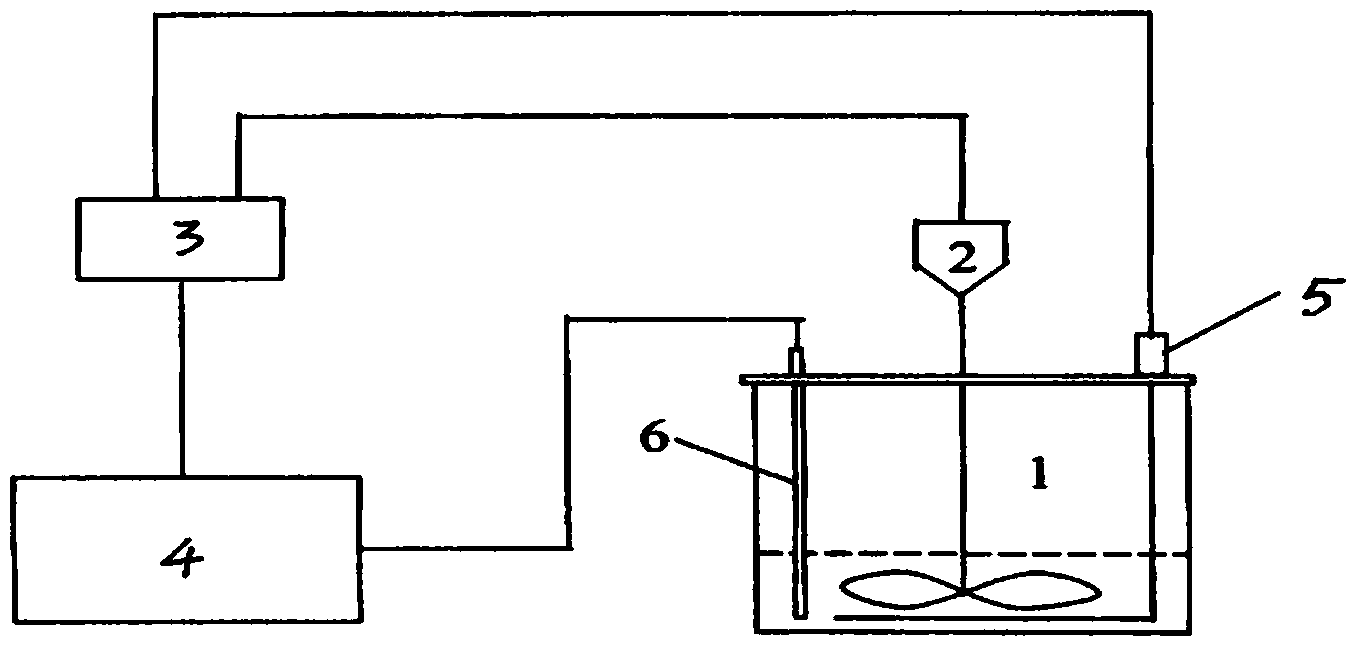

[0036] Corrosion inhibition rate test: According to the national standard GB / T18175-2000, the production is as follows figure 1 The device: including glass cylinder 1, power supply 3, temperature controller 4, power supply 3 and temperature controller 4 are connected, power supply 3 and temperature controller 4 are set outside the glass cylinder 1, temperature controller 4 is also connected w...

Embodiment 2

[0048] Add 38% PESA (polyepoxysuccinate) 35% and 50% HEDP (hydroxyethylidene diphosphoric acid) 12%, 94% zinc sulfate heptahydrate 9%, 30% PAAS (polyacrylic acid) in proportion to the reactor in turn. Sodium) 5%, BTA (benzotriazole) 6%, distilled water 33%; then stirred for 30 minutes to obtain a transparent amber liquid.

[0049] The preparation method is: add hydroxyethylidene diphosphonic acid and water into the reaction kettle, control the temperature at 40°C, then add polyepoxysuccinate, zinc sulfate, sodium polyacrylate, and benzotriazole in sequence in proportion After stirring at 50°C for 30 minutes, a clear amber liquid was obtained.

[0050]Corrosion inhibition performance was tested according to the device and method of Example 1. In this embodiment, the corrosion coupon is made of 20# carbon steel, b=0.010mm / a.

Embodiment 3

[0052] Corrosion and scale inhibitor ingredients: 38% polyepoxysuccinate (PESA), 40%, 50% hydroxyethylidene diphosphonic acid (HEDP), 15%, 94% zinc sulfate heptahydrate, 10%, 30% solid content 6% of sodium polyacrylate, 8% of benzotriazole (BTA), and the rest of water.

[0053] The preparation method is: add hydroxyethylidene diphosphonic acid and water into the reaction kettle, control the temperature at 45°C, then add polyepoxysuccinate, zinc sulfate, sodium polyacrylate, and benzotriazole in sequence in proportion After stirring at 48°C for 30 minutes, a clear amber liquid was obtained.

[0054] The sustained-release performance was tested according to the device and method of Example 1. In this embodiment, the corrosion coupon is made of 20# carbon steel, b=0.012mm / a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com