General corrosion and scale inhibitor for purifying circulating water and preparation and application thereof

A technology of corrosion and scale inhibitor, pure circulating water, applied in descaling and water softening, chemical instruments and methods, complex/solubilizer treatment, etc. The water quality is easy to change and other problems, so as to achieve the effect of insensitive water quality change response, less chemical dosage, and good corrosion inhibition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Corrosion and scale inhibitor ingredients: 38% polyepoxysuccinate (PESA) 30%, 50% hydroxyethylidene diphosphonic acid (HEDP) 10%, 94% zinc sulfate heptahydrate 6%, 30% solid content 3% of sodium polyacrylate, 5% of benzotriazole (BTA), and the rest of water.

[0035] The preparation method is: add hydroxyethylidene diphosphonic acid and water into the reaction kettle, control the temperature at 45°C, then add polyepoxysuccinate, zinc sulfate, sodium polyacrylate, and benzotriazole in sequence in proportion After stirring at 50°C for 30 minutes, a clear amber liquid was obtained.

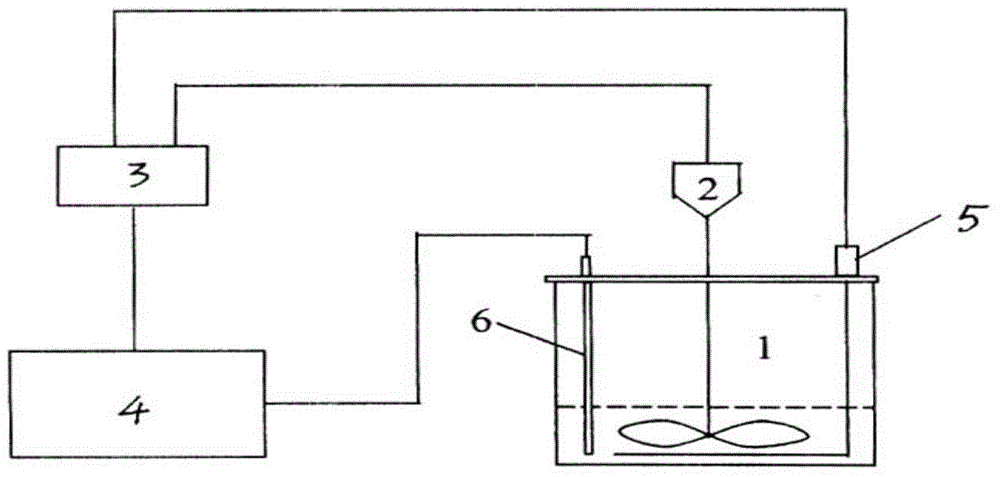

[0036] Corrosion inhibition rate test: According to the national standard GB / T18175-2000, the production is as follows figure 1 The device: including glass cylinder 1, power supply 3, temperature controller 4, power supply 3 and temperature controller 4 are connected, power supply 3 and temperature controller 4 are set outside the glass cylinder 1, temperature controller 4 is also connected w...

Embodiment 2

[0048] Add 38% PESA (polyepoxysuccinate) 35% and 50% HEDP (hydroxyethylidene diphosphoric acid) 12%, 94% zinc sulfate heptahydrate 9%, 30% PAAS (polyacrylic acid) in proportion to the reactor in turn. Sodium) 5%, BTA (benzotriazole) 6%, distilled water 33%; then stirred for 30 minutes to obtain a transparent amber liquid.

[0049] The preparation method is: add hydroxyethylidene diphosphonic acid and water into the reaction kettle, control the temperature at 40°C, then add polyepoxysuccinate, zinc sulfate, sodium polyacrylate, and benzotriazole in sequence in proportion After stirring at 50°C for 30 minutes, a clear amber liquid was obtained.

[0050] Corrosion inhibition performance was tested according to the device and method of Example 1. In this embodiment, the corrosion coupon is made of 20# carbon steel, b=0.010mm / a.

Embodiment 3

[0052] Corrosion and scale inhibitor ingredients: 38% polyepoxysuccinate (PESA), 40%, 50% hydroxyethylidene diphosphonic acid (HEDP), 15%, 94% zinc sulfate heptahydrate, 10%, 30% solid content 6% of sodium polyacrylate, 8% of benzotriazole (BTA), and the rest of water.

[0053] The preparation method is: add hydroxyethylidene diphosphonic acid and water into the reaction kettle, control the temperature at 45°C, then add polyepoxysuccinate, zinc sulfate, sodium polyacrylate, and benzotriazole in sequence in proportion After stirring at 48°C for 30 minutes, a clear amber liquid was obtained.

[0054] The sustained-release performance was tested according to the device and method of Example 1. In this embodiment, the corrosion coupon is made of 20# carbon steel, b=0.012mm / a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com