High-strength steel wire cord with high rubber infiltration rate

A technology of high-strength steel wire and high glue penetration rate, which is applied in the field of steel cords, can solve problems such as uncertainty and discounted glue penetration of cords, and achieve the effects of improving production efficiency, solving core leakage problems, and avoiding rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

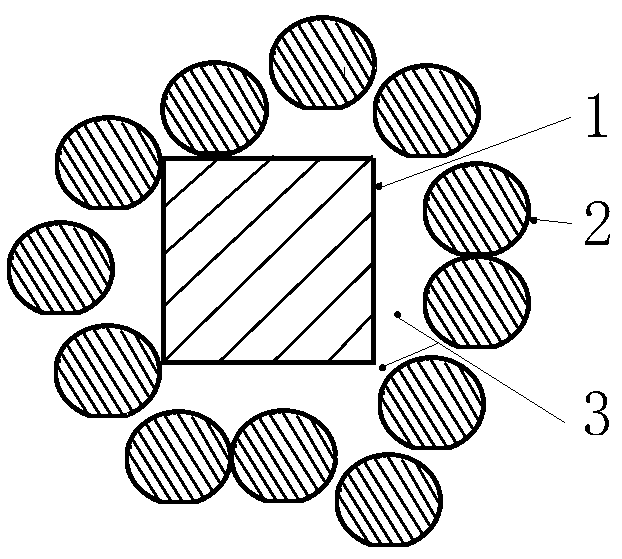

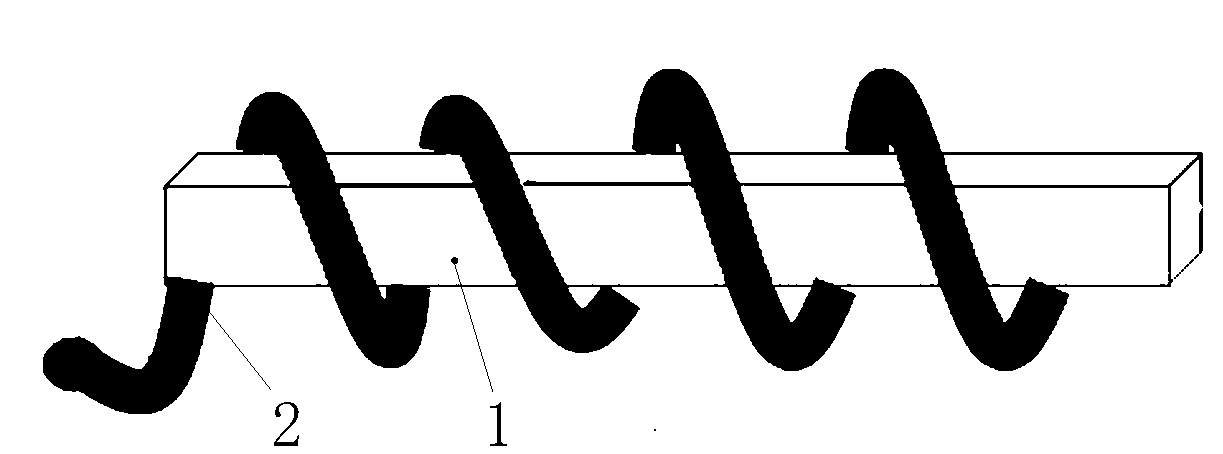

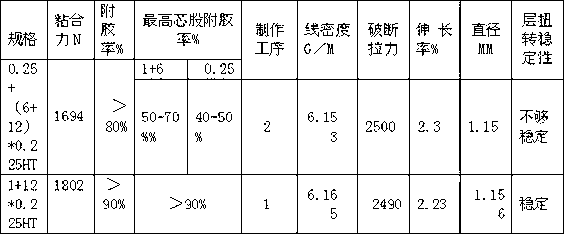

[0018] refer to Figure 1-2 , a high-strength steel cord with high glue penetration rate, including a core steel wire 1 in the middle, and its periphery is wrapped with a single-layer structure formed by twisting 12 surrounding steel wires 2; the cross-section of the core steel wire 1 is Square, in which the diameter of the circumscribed circle of the core steel wire (D 芯 ) and the diameter of the surrounding steel wire (d 外 ) should satisfy: 3(d 外 )+0.04>(D 芯 )>3(d 外 ) +0.01.

[0019] The steel cord production adopts a single-twisting tube machine, which puts 12 spindles inside and a core strand pay-off spindle outside; the bobbin rotates in the Z direction, and the twist length is controlled at 18mm; a pre-deformer is added at the outlet to ensure that it is not loose and Install a straightener to ensure that the stress of the cord is relieved and the straightness is good; the steel cord of the model 1+12*0.225HT is used for the carcass or belt of the rubber tire, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com