Lithium-loaded composite framework material as well as preparation method and application thereof

A framework material and lithium analysis technology, applied in the field of lithium-loaded composite framework materials and their preparation, can solve the problems of large volume effect, interface side reactions, etc., and achieve the effects of uniform deposition, reduced contact, and good gradient lithium-philic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

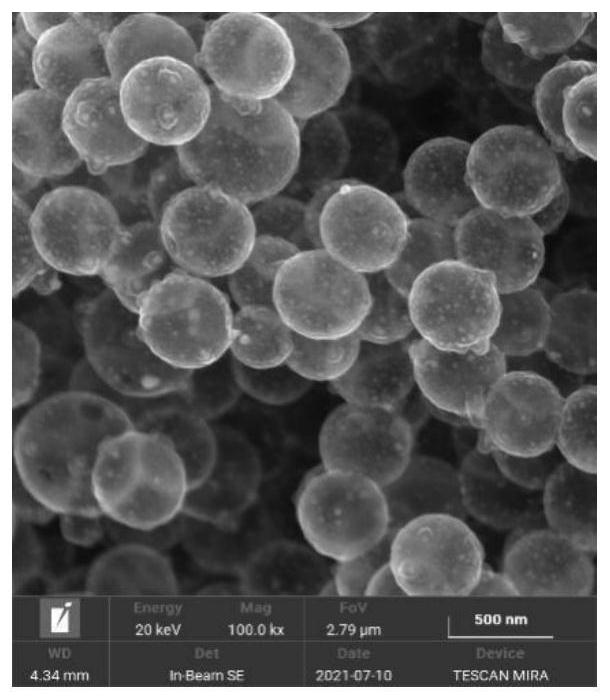

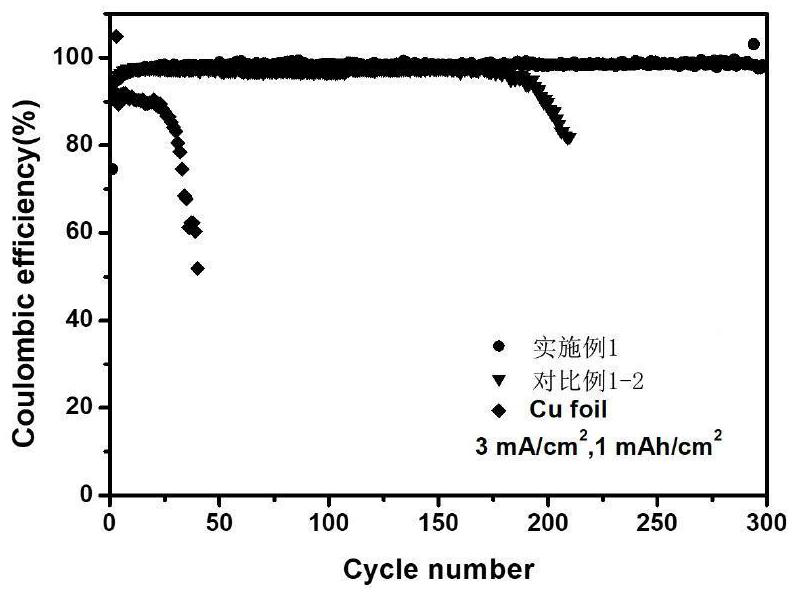

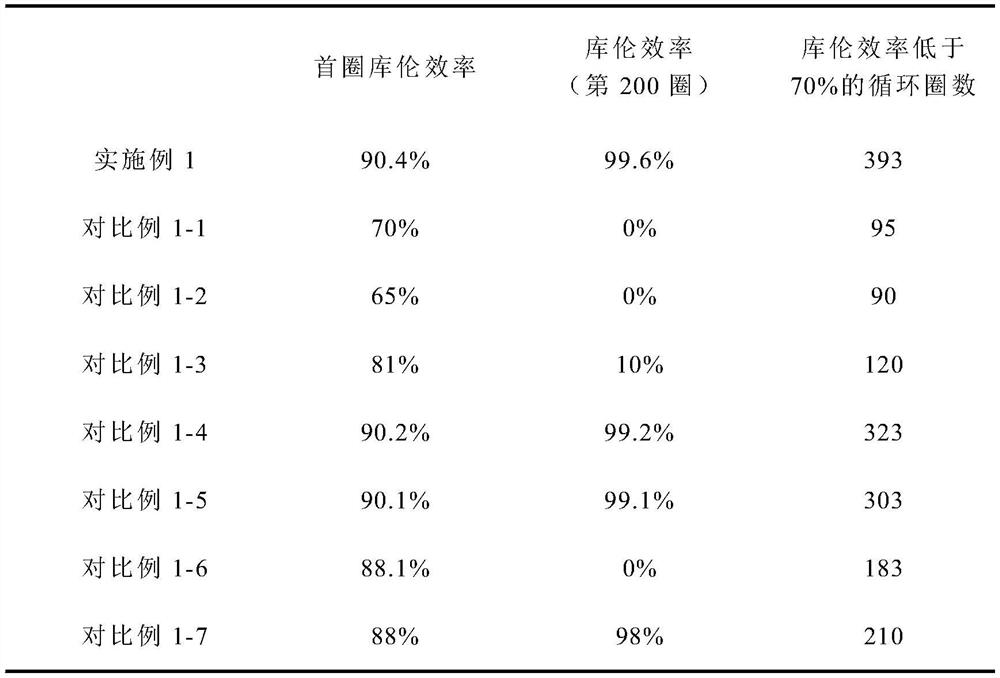

[0073] SiO with an average diameter of 500 nm 2 The ball is configured into a 10g / L sol, using a tin protochloride solution with a concentration of 0.05mol / L, SiO 2 The volume ratio of the sol to the stannous chloride solution is 1:2, activate at room temperature for 3 hours, filter with suction, rinse with deionized water and disperse in 100ml of deionized water, add 100ml of 0.025mol / L AgNO 3 Solution, add ammonia solution dropwise to prepare silver ammonia solution, then add 125ml 0.01mol / L glucose solution dropwise and stir in water bath at 50°C for 2h to prepare SiO 2 @Ag. SiO 2 After cleaning @Ag, disperse in 50ml water, add 0.25g dopamine, 0.25g trishydroxyaminomethane, pH is 8.5, stir at room temperature for 24h to obtain the SiO 2 @Ag@Carbon Source; After filtration and cleaning, it is mixed with water to form a suspension with a solid-to-liquid ratio of 40%, and the spray temperature is set to 200°C to prepare secondary particles stacked with hollow thin-walled na...

Embodiment 2

[0092] SiO with an average diameter of 500 nm 2 The ball is configured into a 10g / L sol, using a tin protochloride solution with a concentration of 0.05mol / L, SiO 2 The volume ratio of the sol to the stannous chloride solution is 1:2, activate at room temperature for 3 hours, filter with suction, rinse with deionized water and disperse in 100ml of deionized water, add the activated template to a concentration of 0.1mol / L Zn(NO 3 ) 2 , then add polyethylene glycol solution, then add 0.0001mol / L KOH solution, stir for 2h to obtain ZnO nanoparticles, add 0.5g dopamine, 0.5g trishydroxyaminomethane, pH is 8.5, stir at room temperature for 24h to obtain the SiO 2@ZnO@Carbon Source; After filtering and cleaning, it is mixed with water to make a suspension with a solid-to-liquid ratio of 40%, and the spray temperature is set to 200°C to prepare secondary particles stacked with hollow thin-walled carbon nanospheres. The secondary particles were cleaned and a suspension of 10 g / L wa...

Embodiment 3

[0103] SiO with an average diameter of 500 nm 2 The ball is configured into a 10g / L sol, using a tin protochloride solution with a concentration of 0.05mol / L, SiO 2 The volume ratio of the sol to the stannous chloride solution is 1:2, activate at room temperature for 3 hours, filter with suction, rinse with deionized water and disperse in 100ml of deionized water, add the activated template to a concentration of 0.1mol / L Cu(NO 3 ) 2 , then add aqueous solution, then add formaldehyde solution, stir for 2h to obtain SiO 2 @Cu, in H 2 / N 2 SiO was obtained by plasma at 450°C for 2h in a mixed atmosphere 2 @Cu x N, add 0.5g dopamine, 0.5g trishydroxyaminomethane, pH is 8.5, stir at room temperature for 24h to obtain the SiO 2 @Cu x N@carbon source; after filtering and cleaning, prepare a suspension with a solid-to-liquid ratio of 40% with water, and set the spray temperature to 200°C to prepare secondary particles stacked with hollow thin-walled carbon nanospheres. The se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com