Rear supporting point triangular bracket hanging basket and bridge construction method using same

A technology of triangular brackets and rear fulcrums, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of relatively large position restrictions of cable stays, unrecoverable embedded parts, and many embedded parts. The effect of moving construction operations, solving adverse effects, and light appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] For ease of understanding, the direction along the bridge is now referred to as the longitudinal or longitudinal direction, and the direction across the bridge is referred to as the transverse or transverse direction. Define the forward direction of construction as front and the opposite direction as rear.

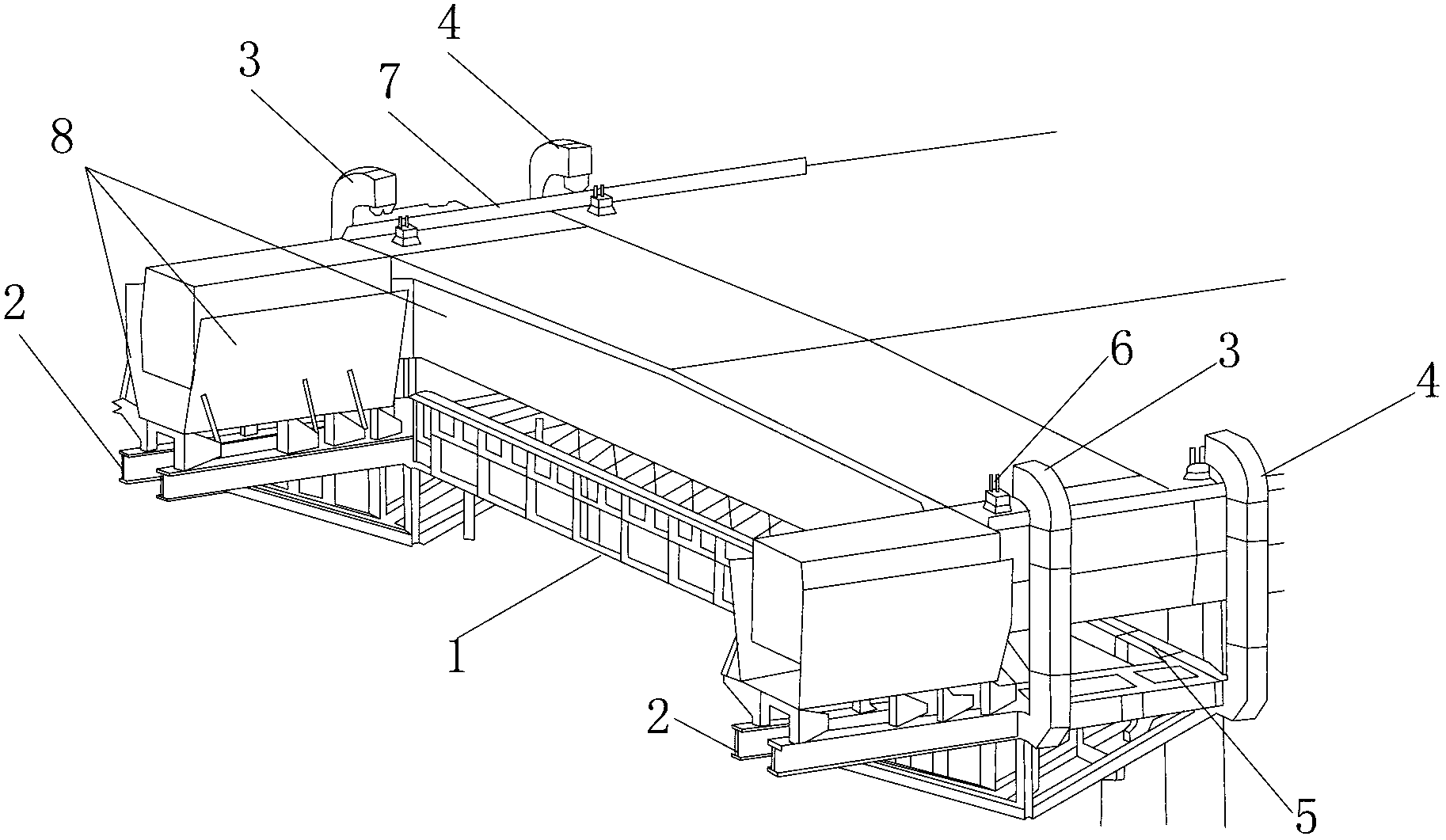

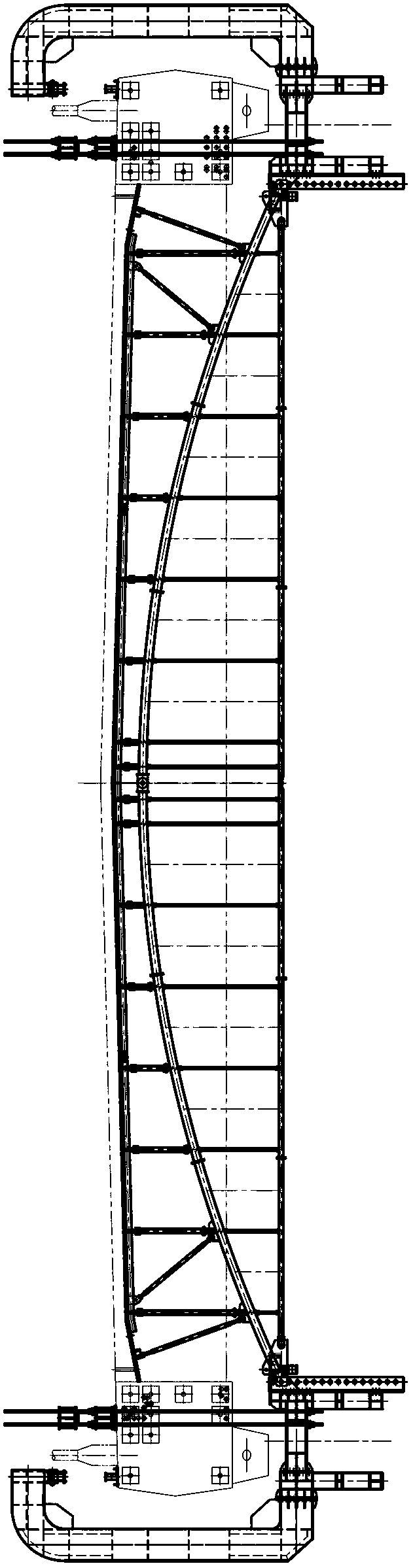

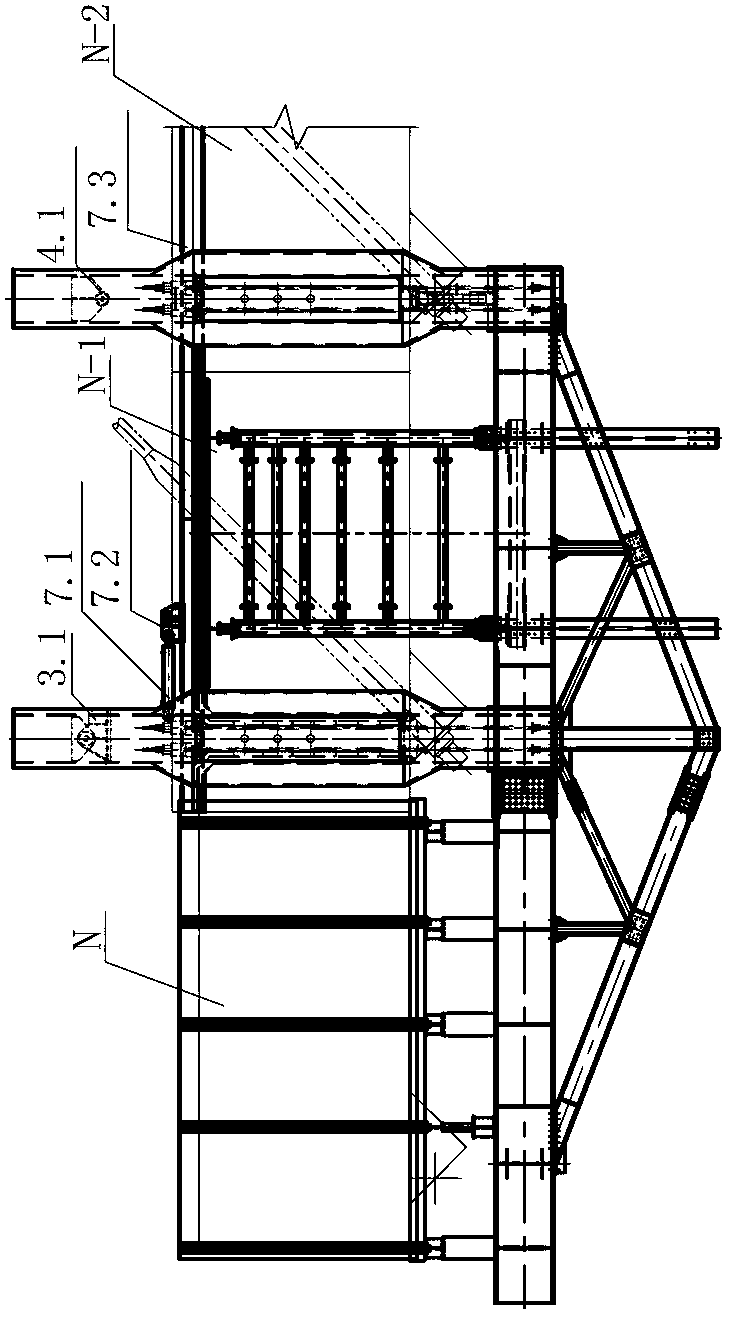

[0050] like Figures 1 to 6 Each figure can see the hanging basket of the present invention, which includes:

[0051] The load-bearing platform consists of left and right main longitudinal beams 2 located on both sides of the cross section of the bridge, a first beam 1 connecting the midpoint of the left and right main longitudinal beams 2, and connecting the left and right main longitudinal beams in the forward direction side The second beam 5 at the end is formed. Wherein, the bottoms of the left and right main longitudinal beams 2 are respectively provided with diagonal braces, which form an inverted triangular truss structure with the main longitudinal beams 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com