Dual-meshing needle finger cam indexing mechanism

A cam indexing, double meshing technology, applied in belt/chain/gear, mechanical equipment, transmission, etc., can solve the problems of limited transmission torque, concentrated contact fatigue strength, damage, etc., to achieve smooth transmission, easy processing and manufacturing, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

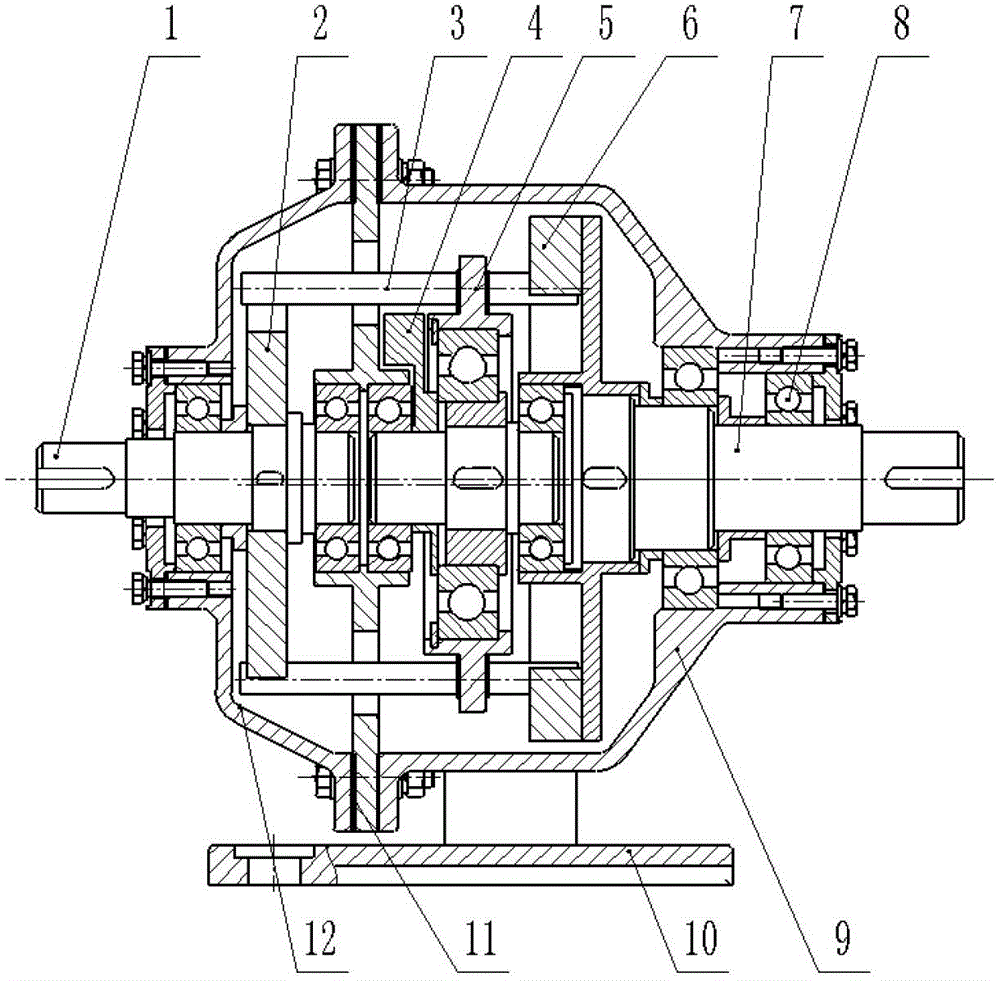

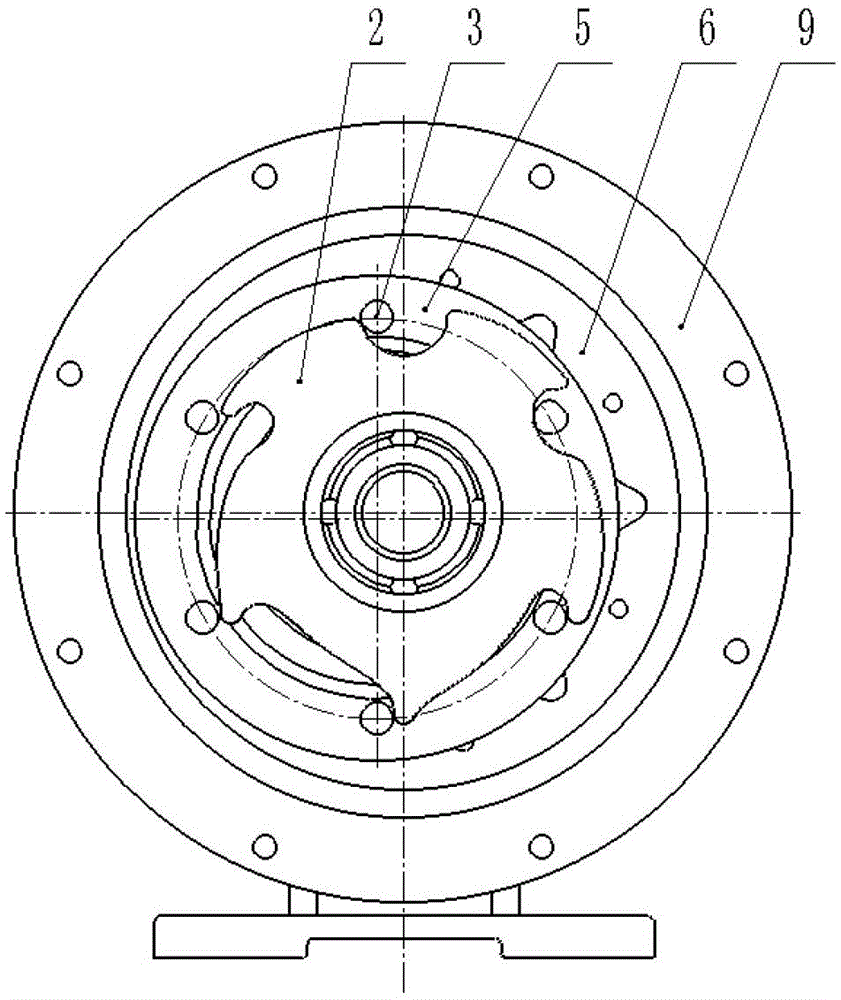

[0027] A double meshing needle cam indexing mechanism, as shown in the accompanying drawings, includes a chassis, a machine base 10, an input shaft 7, an output shaft 1, a hypocycloid wheel 6, a pin wheel 5, pin teeth 3 and an indexing cam 2 , on the upper end of the machine base, the chassis is fixed, and the chassis includes a front cover 9, a baffle plate 11 and a rear cover 12 fixed in sequence through a flange, and the front cover, the baffle plate and the middle part of the rear cover are all coaxially shaped for supporting Bearing bores for input and / or output shafts;

[0028] The input shaft is coaxially installed in the bearing hole made by the front cover and the baffle, and a hypocycloid w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com