Cold gas carrying spray head structure of direct contact type ice slurry generator

A gas nozzle, contact technology, applied in the field of direct contact ice slurry generator cooling gas nozzle structure, to achieve the effect of saving investment cost, reducing leakage and reducing maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

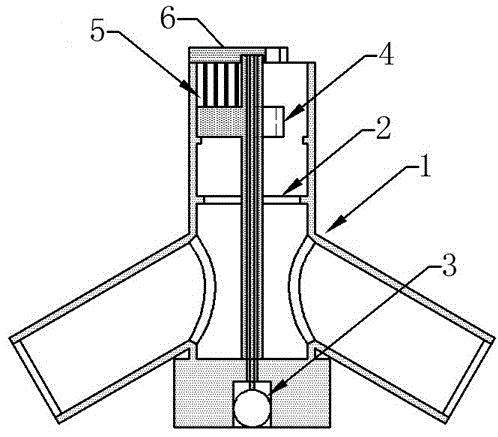

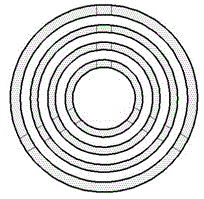

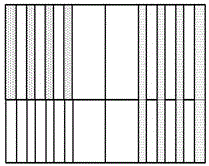

[0019] As shown in the figure, the structure of the cold-carrying gas nozzle of the direct contact ice slurry generator includes a gas tee structure 1, a wire mesh 2, a gear motor 3, a waterproof casing and support ribs 4, a concentric annular flow channel 5 and a deicer 6 , the deicer 6 includes a transmission shaft 6.1, a bracket 6.2, a deicing blade 6.3, and a waterproof groove 6.4; a mesh 2 is provided in the middle of the gas tee structure 1, a reduction motor 3 is provided at the lower end, and a concentric annular flow channel 5 is provided at the upper end , the deceleration motor 3 is connected to the lower end of the transmission shaft 6.1, the transmission shaft 6.1 is provided with a waterproof sleeve and a support rib 4, the concentric annular flow channel 5 is fixed on the waterproof sleeve and the support rib 4, and the lower surface of the bracket 6.2 is vertically provided with a deicing The blade 6.3 and the bracket 6.2 are 3 arms at 120 degrees. The lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com