Application of polyvinylidene fluoride-chlorotrifluoroethylene film as oxygenation film

A technology of chlorotrifluoroethylene and polyvinylidene fluoride, applied in membrane, membrane technology, semi-permeable membrane separation and other directions, can solve problems such as excessive pore size and blood leakage, achieve small separation pore size, reduce damage, and resist blood leakage Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

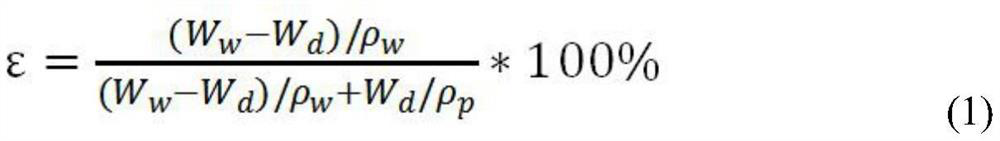

Embodiment 1

[0044] Put 20wt% PVDF-CTFE resin, 10wt% polyethylene glycol (molecular weight 4000) and 70wt% solvent dimethylacetamide into the spinning kettle, stir at 90°C for 6 hours to dissolve evenly, and let it stand for 4 hours for defoaming , together with the core liquid water, is inserted into the tubular spinning nozzle, extruded, and enters the coagulation bath tank. At a spinning draft speed of 20 m / min, a PVDF-CTFE hollow fiber membrane is spun out. After washing, Dry directly to obtain PVDF-CTFE oxygenated membrane. The PVDF-CTFE oxygenated membrane has an inner diameter of 200 μm and a wall thickness of 40 μm. The inner wall of the membrane filament is smooth and flat, without a dense outer skin layer, which can allow blood to flow through the tube. The gas permeation rate is 35mL / min·cm 2 ·bar, the water penetration pressure is 0.50MPa, the maximum pore size measured by the ethanol bubble point method is 0.06μm, the porosity is 83%, and the plasma leakage time is greater th...

Embodiment 2

[0050] Put 25wt% PVDF-CTFE resin, 10wt% ethylene glycol and 65wt% solvent N-methylpyrrolidone into the spinning kettle, stir at 70°C for 6 hours to dissolve evenly, let stand for defoaming for 4 hours, and mix with dimethyl ethyl The core liquid of the aqueous solution with an amide content of 70wt% is inserted into the tubular spinning nozzle, extruded, and enters the coagulation bath tank, and the PVDF-CTFE hollow fiber is spun at a spinning draft speed of 60 m / min The membrane was washed with water and dried directly to obtain a PVDF-CTFE oxygenated membrane. The PVDF-CTFE oxygenated membrane has an inner diameter of 200 μm and a wall thickness of 50 μm. The gas permeation rate is 22mL / min·cm 2 ·bar, the water penetration pressure is 0.60MPa, the maximum pore size measured by the ethanol bubble point method is 0.08μm, the porosity is 81%, and the plasma leakage time is greater than 20 days.

Embodiment 3

[0052] Put 20wt% polyvinylidene fluoride-chlorotrifluoroethylene resin, 8wt% polyethylene glycol (molecular weight 200) and 72wt% solvent sulfolane into the spinning kettle, stir at 80°C for 6 hours to dissolve evenly, and let it stand for degassing for 4 After one hour, together with the core liquid of the aqueous solution with a dimethylacetamide content of 70wt%, by inserting a tubular spinning nozzle, extruding, entering the coagulation bath water tank, under the spinning drafting speed of 60 m / min, A PVDF-CTFE hollow fiber membrane is spun, washed with water, and dried to obtain a PVDF-CTFE oxygenated membrane. The PVDF-CTFE oxygenated membrane has an inner diameter of 200 μm and a wall thickness of 60 μm. The gas permeation rate is 32mL / min·cm 2 ·bar, the water penetration pressure is 0.40MPa, the maximum pore size measured by the ethanol bubble point method is 0.05μm, the porosity is 84%, and the plasma leakage time is greater than 20 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com