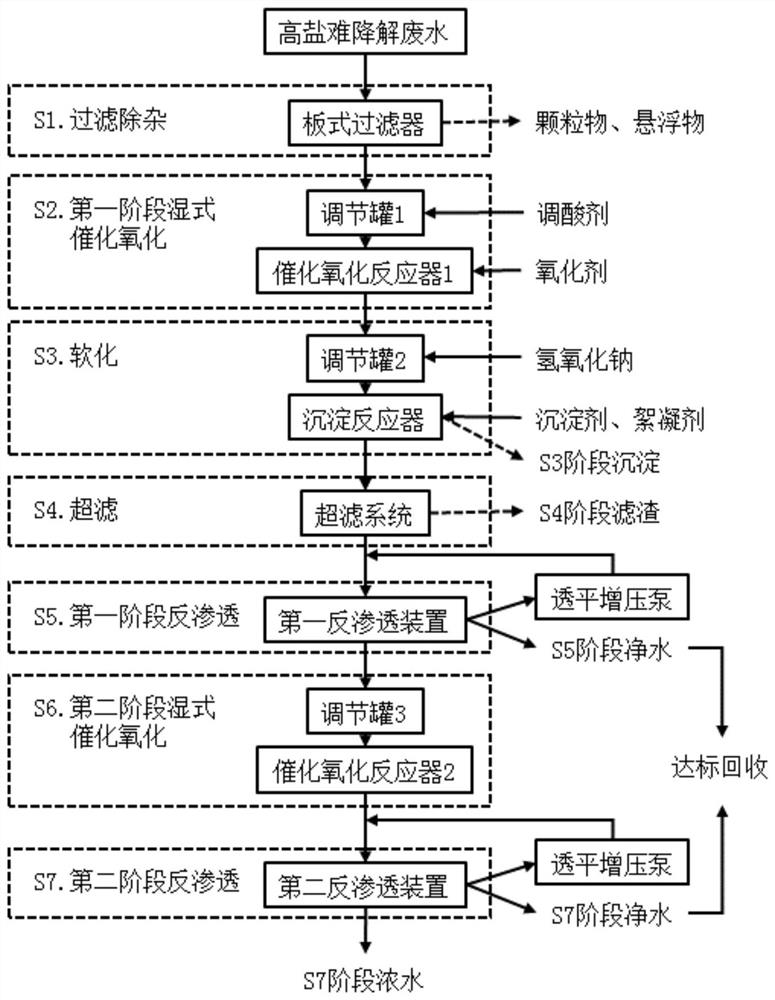

Method and system for treating high-salt degradation-resistant wastewater

A technology for wastewater treatment and refractory degradation, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc. The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A chemical company has high-salt wastewater containing sodium chloride and sodium sulfate, with a total salt content of 1% to 2%, COD500mg / L or so, and the water body is light yellow.

[0058] S1. Filtration to remove impurities, the waste water is passed through a plate filter to filter out particulate matter and suspended matter. S2. After the first-stage wet catalytic oxidation treatment of the wastewater, the COD can be reduced to below 50mg / L or even below 10mg / L (realized by adjusting the amount of oxidant), and the treated effluent is clear and colorless. S3. After softening and removing hardness, flocculation and precipitation, Ca 2+ , Mg 2+ Plasma content can be reduced to below 50mg / L. S4. The high salt water is initially filtered through the ultrafiltration system. S5. In the first stage of reverse osmosis, the purified water produced reaches the reuse standard for reuse. After the first stage of reverse osmosis concentration, the concentrated water COD re...

Embodiment 2

[0060] A coking enterprise has wastewater containing sodium chloride, the salt content is about 2%, the COD is about 1800mg / L, and the water body is orange-yellow.

[0061] S1. Filtration to remove impurities, the waste water is passed through a plate filter to filter out particulate matter and suspended matter. S2. After the waste water is treated by wet catalytic oxidation in the first stage, the COD can be reduced to below 50 mg / L, and the effluent after treatment is basically colorless. S3. After softening and removing hardness, flocculation and precipitation, Ca 2+ , Mg 2+ Plasma content can be reduced to below 50mg / L. S4. The high salt water is initially filtered through the ultrafiltration system. S5. In the first stage of reverse osmosis, the purified water produced reaches the reuse standard for reuse. After the first stage of reverse osmosis concentration, the concentrated water COD reaches about 200mg / L, and the salt content is greater than 6%. Enter S6. The seco...

Embodiment 3

[0063] A certain enterprise has wastewater containing sodium chloride, the salt content is about 1.5%, the COD is about 1000mg / L, and the water body is yellow.

[0064] S1. Filtration to remove impurities, the waste water is passed through a plate filter to filter out particulate matter and suspended matter. S2. After the waste water is treated by wet catalytic oxidation in the first stage, the COD can be reduced to about 40mg / L, and the effluent after treatment is clear and colorless. S3. After softening and removing hardness, flocculation and precipitation, Ca 2+ , Mg 2+ Plasma content can be reduced to below 50mg / L. S4. The high salt water is initially filtered through the ultrafiltration system. S5. In the first stage of reverse osmosis, the purified water produced reaches the reuse standard for reuse. After the first stage of reverse osmosis concentration, the concentrated water COD reaches about 200mg / L, and the salt content is about 5%. Enter S6. The second stage We...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com