A process for recycling wood pulp and papermaking black liquor

A technology for papermaking black liquor and recycling, which is applied in the regeneration of alkali liquor, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. , complex process and other problems, to achieve the effect of energy saving, emission reduction and recycling, wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

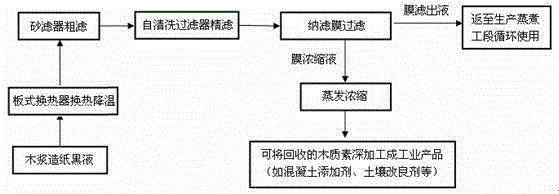

Image

Examples

Embodiment 1

[0025] A method for recycling wood pulp and papermaking black liquor, the specific steps are as follows:

[0026] (1) will be 60m 3 The wood pulp and papermaking black liquor with a processing capacity of / h is heat-exchanged through a plate heat exchanger, and its temperature is controlled at 20-50°C. The pH of the wood pulp and papermaking black liquor is 12.5-13.5, and the solid content is 10-12%. Suspended matter content is less than 30mg / L.

[0027] (2) The 60m after heat exchange 3 / h Wood pulp and papermaking black liquor is coarsely filtered with a sand filter. The sand filter adopts an anti-corrosion shell lined with carbon steel and hard rubber, and is filled with ASM special sand and gravel filter material. The patented product of Israel ARKAL company, its particle size is 0.6-0.7mm. The total filtration area of the sand filter is 4.52m 2 , the height of the filter layer of the special sand and gravel filter material is 50cm, and the filter operation paramete...

Embodiment 2

[0031] The method and device for recycling wood pulp and papermaking black liquor in this embodiment are substantially the same as those in Embodiment 1. The differences are: 1) The solid matter concentration of the treated wood pulp and papermaking black liquor is about 15%, and the suspended matter content is about 40mg / L; 2) The operating parameters of the coarse filtration process are: the inlet pressure is about 0.4MPa, the backwash pressure About 0.4MPa, filtration rate of about 15m / h, backwash interval time of about 4h, backwash flow rate of about 45m / h, flushing time of about 2min; 3) The selected self-cleaning filter is made of polypropylene laminated sheets, and the filtration accuracy is 100μm , the operating parameters of the fine filtration process are: operating pressure 0.5MPa, external source backwashing, backwashing pressure 0.7MPa, backwashing flow 50m 3 / h, the backwashing interval is about 2.5h, each filter unit is backwashed one by one in sequence, the bac...

Embodiment 3

[0033] The method and device for recycling wood pulp and papermaking black liquor in this embodiment are substantially the same as those in Embodiment 1. The differences are: 1) The solid matter concentration of the processed wood pulp and papermaking black liquor is about 18%, and the suspended matter content is 50mg / L; About 0.5MPa, filtration rate about 20m / h, backwash interval time about 2h, backwash flow rate about 50m / h, flushing time about 3min; 3) The selected self-cleaning filter is made of polypropylene laminated sheets, and the filtration accuracy is 200μm , the operating parameters of the fine filtration process are: the operating pressure is about 1.0MPa, the external source backwashing is adopted, the backwashing pressure is 1.0MPa, and the backwashing flow rate is 50m 3 / h, the backwashing interval is about 1.5h, each filter unit is backwashed one by one in sequence, the backwashing time of each unit is about 30 seconds, and the backwashing interval of each unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com