Production process of Lipstatin

A production process, lipox technology, applied in the field of drug synthesis, can solve the problems of low fermentation titer and high production cost, and achieve the effect of low fermentation cost, low cost and short fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

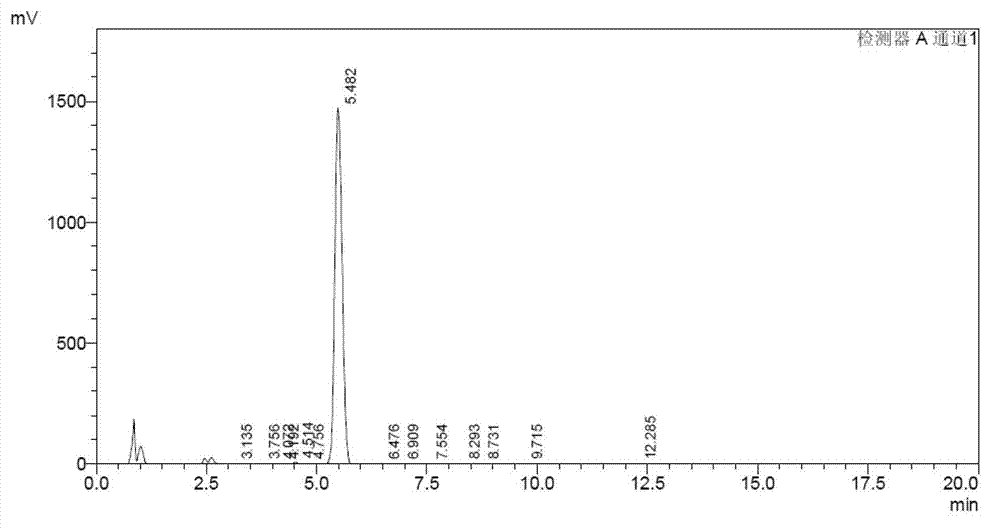

[0036] Example 1 A production process of riprestatin

[0037] Including the following steps:

[0038] A. Preparation of fermentation medium

[0039] In terms of mass percentage, the formula of 20L fermentation medium is: 2.5% glycerin, 3% soybean powder, 1.5% lecithin, 5% sunflower oil, 0.01% magnesium sulfate, 0.05% calcium carbonate, appropriate amount of trace elements (chlorinated Manganese: 0.001%, zinc chloride 0.0015%), and the balance is deionized water. Sterilize the culture medium by conventional methods.

[0040] B. Inoculation, fermentation culture

[0041] Streptomyces toxin was inoculated in the fermentation medium, the inoculum amount was 5% (V / V) of the fermentation broth, and the strain concentration of the bacteria solution was 15%; fermented at 27°C±1°C for 8 days; using hydrogen oxidation Sodium and hydrochloric acid are automatically balanced to adjust the pH value of the fermentation broth, so that the pH value is maintained at 7.0; during the ferment...

Embodiment 2

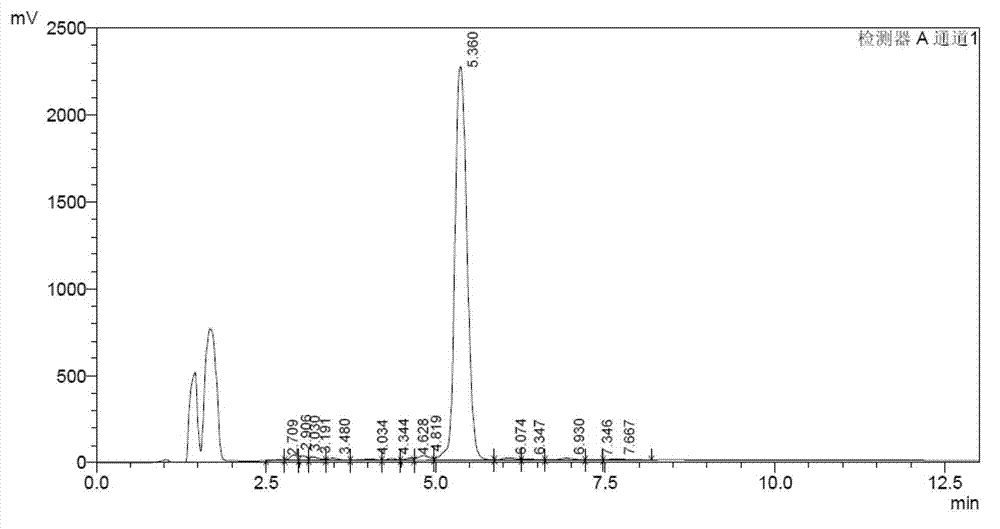

[0051] Embodiment 2 A kind of production process of riprestatin

[0052] Including the following steps:

[0053] A. Preparation of fermentation medium

[0054] In terms of mass percentage, the formula of 20L fermentation medium is: 3% glycerin, 4.5% soybean powder, 2% lecithin, 8% sunflower oil, 0.05% magnesium sulfate, 0.2% calcium carbonate, appropriate amount of trace elements (chloride Manganese: 0.001%, zinc chloride 0.0015%), and the balance is deionized water. Sterilize the culture medium by conventional methods.

[0055] B. Inoculation, fermentation culture

[0056]Streptomyces toxin was inoculated in the fermentation medium, the inoculation amount was 8% (V / V) of the fermentation broth, and the strain concentration of the bacteria solution was 20%; fermented at 27°C±1°C for 7 days; using hydrogen oxidation Sodium and hydrochloric acid are automatically balanced to adjust the pH value of the fermentation broth, so that the pH value is maintained at 7.0; during the ...

Embodiment 3

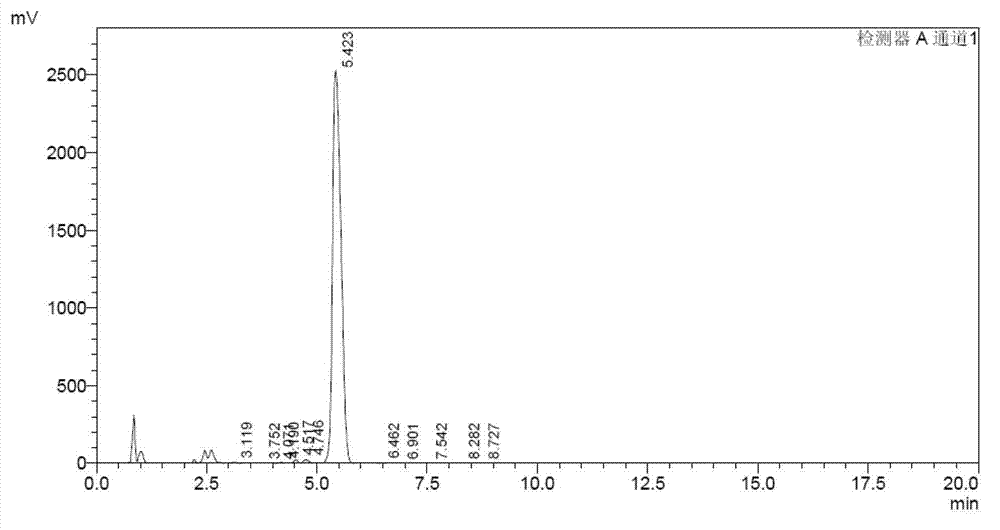

[0066] Example 3 A production process of riprestatin

[0067] Including the following steps:

[0068] A. Preparation of fermentation medium

[0069] In terms of mass percentage, the formula of 20L fermentation medium is: 4.5% glycerin, 6.5% soybean powder, 4% lecithin, 9% sunflower oil, 0.15% magnesium sulfate, 0.4% calcium carbonate, appropriate amount of trace elements (chloride Manganese: 0.001%, zinc chloride 0.0015%), and the balance is deionized water. Sterilize the culture medium by conventional methods.

[0070] B. Inoculation, fermentation culture

[0071] Streptomyces toxin was inoculated in the fermentation medium, the inoculation amount was 10% (V / V) of the fermentation broth, and the strain concentration of the bacteria solution was 20%; fermented at 27°C±1°C for 8 days; using hydrogen oxidation Sodium and hydrochloric acid are automatically balanced to adjust the pH value of the fermentation broth, so that the pH value is maintained at 7.0; during the ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com