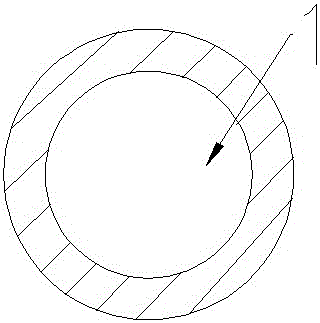

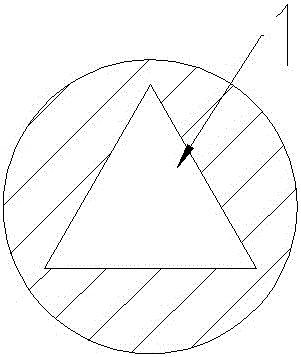

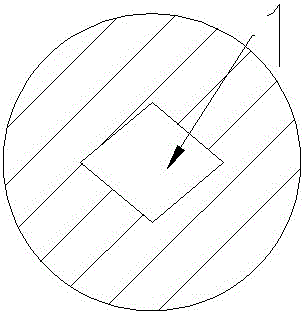

A mold for superhard material synthesis

A technology of superhard materials and molds, which is applied in the field of molds and can solve problems such as unstable synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A mold for synthesizing superhard materials is made of the following raw materials: a low-melting substance with a melting point range of 800-1000°C, a high-melting point substance with a melting point range of 1000-1800°C, and dolomite. The low melting point substance is sodium chloride, and the high melting point substance is magnesium oxide and aluminum oxide. Substances with low melting point ensure a more uniform pressure field in the synthesis cavity, which greatly improves the stability of synthesis; substances with high melting point make the mold still have high strength at high temperatures, ensuring the stability of synthesis; dolomite will undergo special Phase change, the volume becomes larger, to a certain extent, it compensates for the pressure drop caused by the volume shrinkage of the material after sintering.

[0018] The parts by weight of the sodium chloride, magnesium oxide, aluminum oxide and dolomite are respectively 5-40 parts, 5-30 parts, 10-40 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com